CONTENTS

1. Outline .........................................................................................................................................

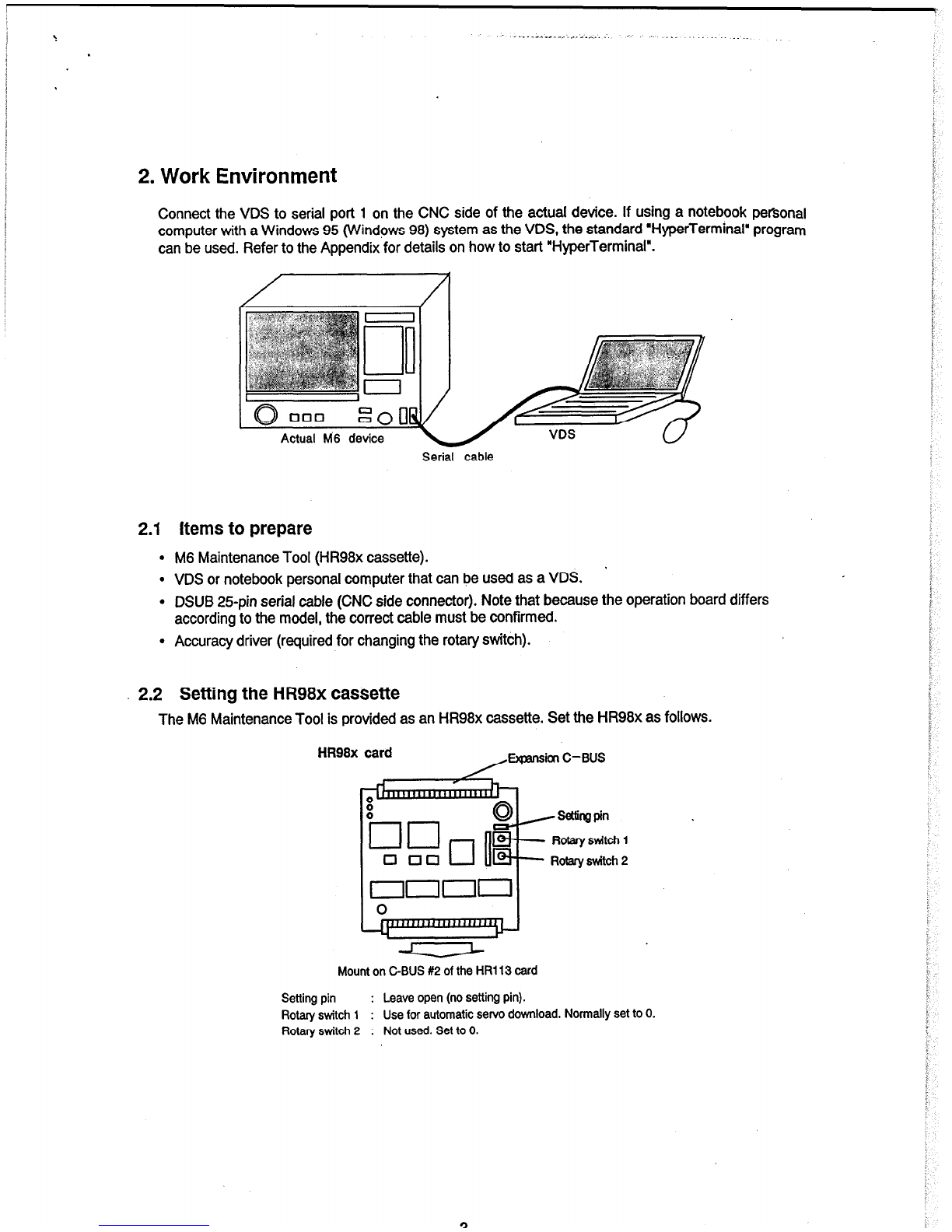

2. Work Environment ..............................................................................................................................

2.1 Items to prepare.. ........................................................................................................................

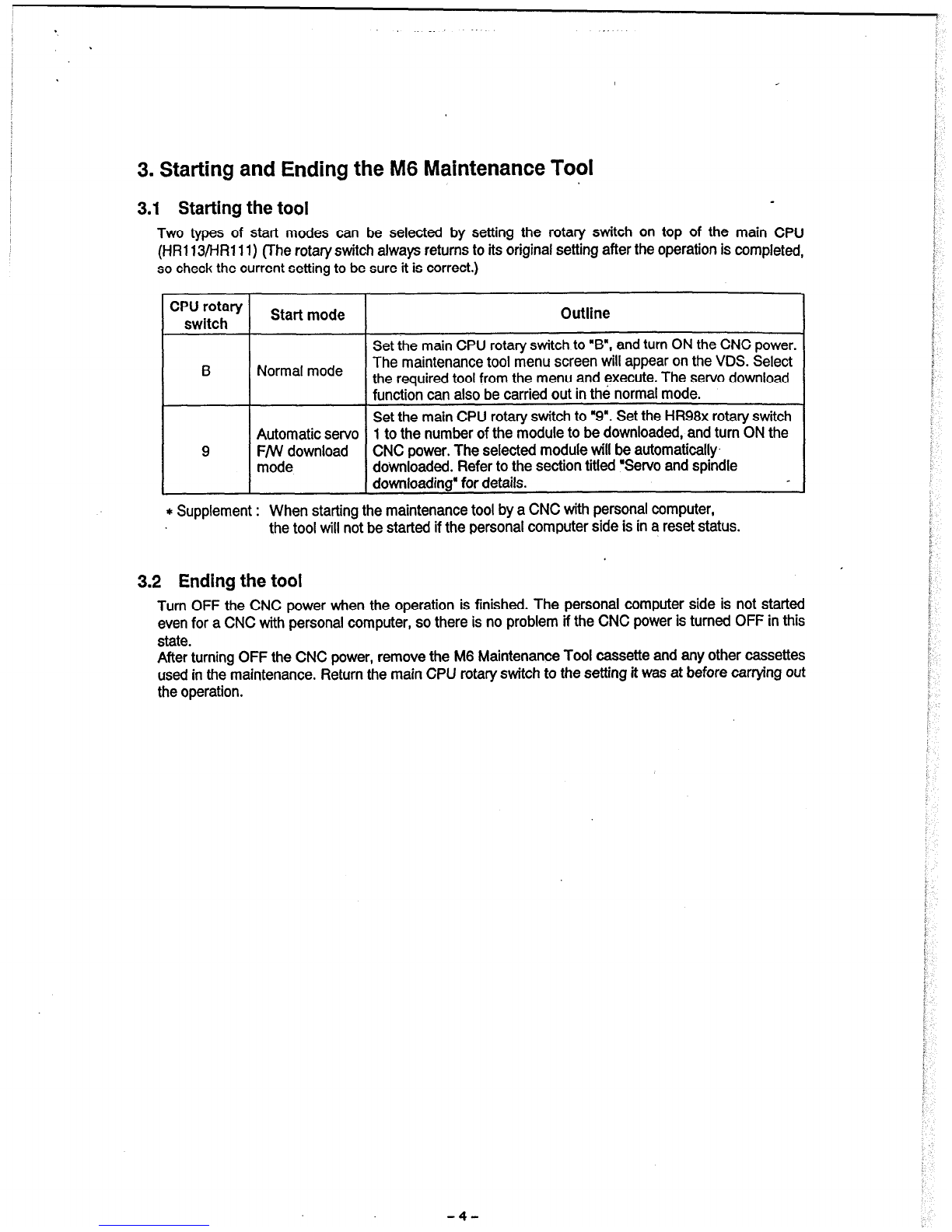

2.2 Setting the HR98x caxx$te .......................................................................................................

2.3 Mounting the maintenance tool cassette.. ..................................................................................

3. Starting and Ending the M6 Maintenance Tool ..............................................................................

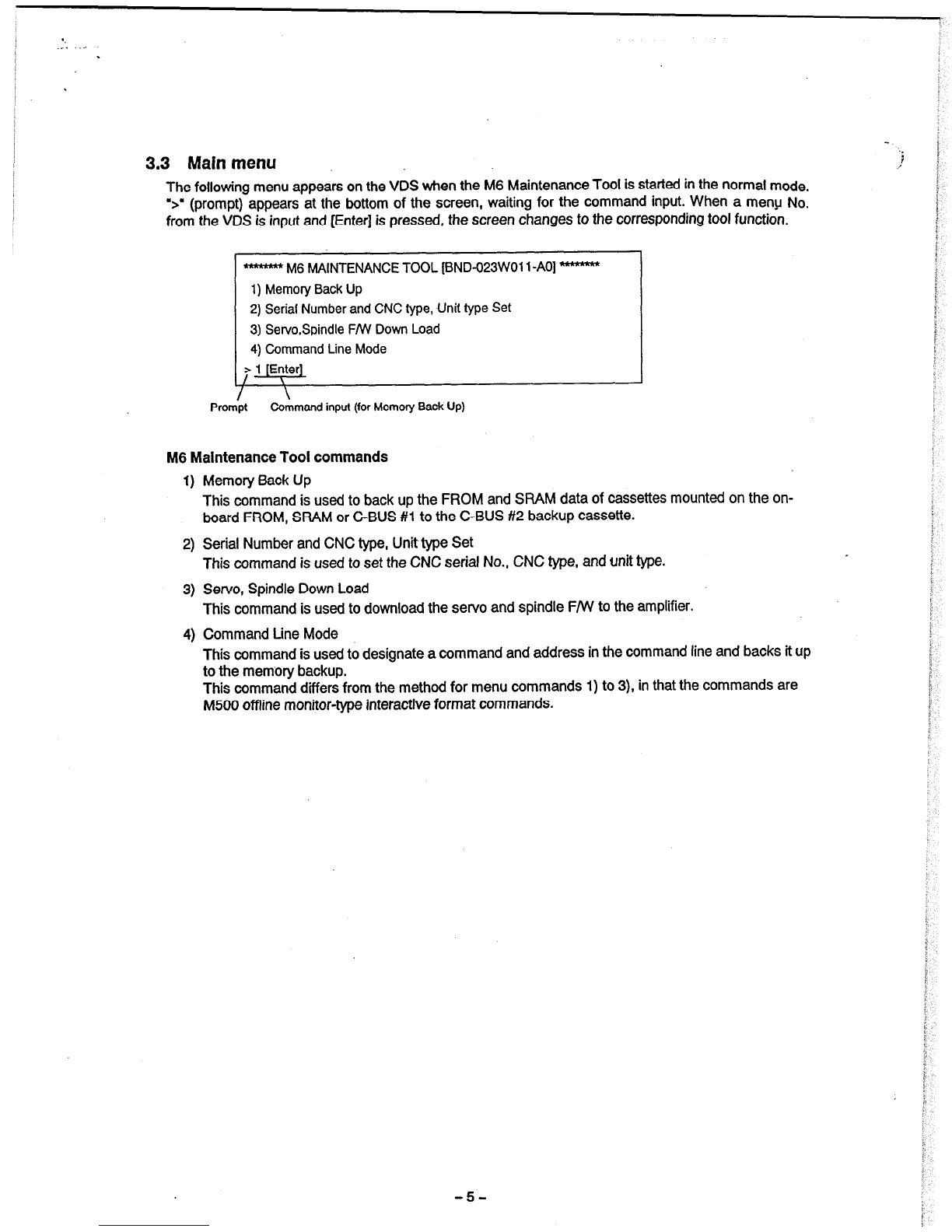

3.1 Starting the tool ...........................................................................................................................

3.2 Ending the tool.............................................................................................................................

3.3 Main menu.. .................................................................................................................................

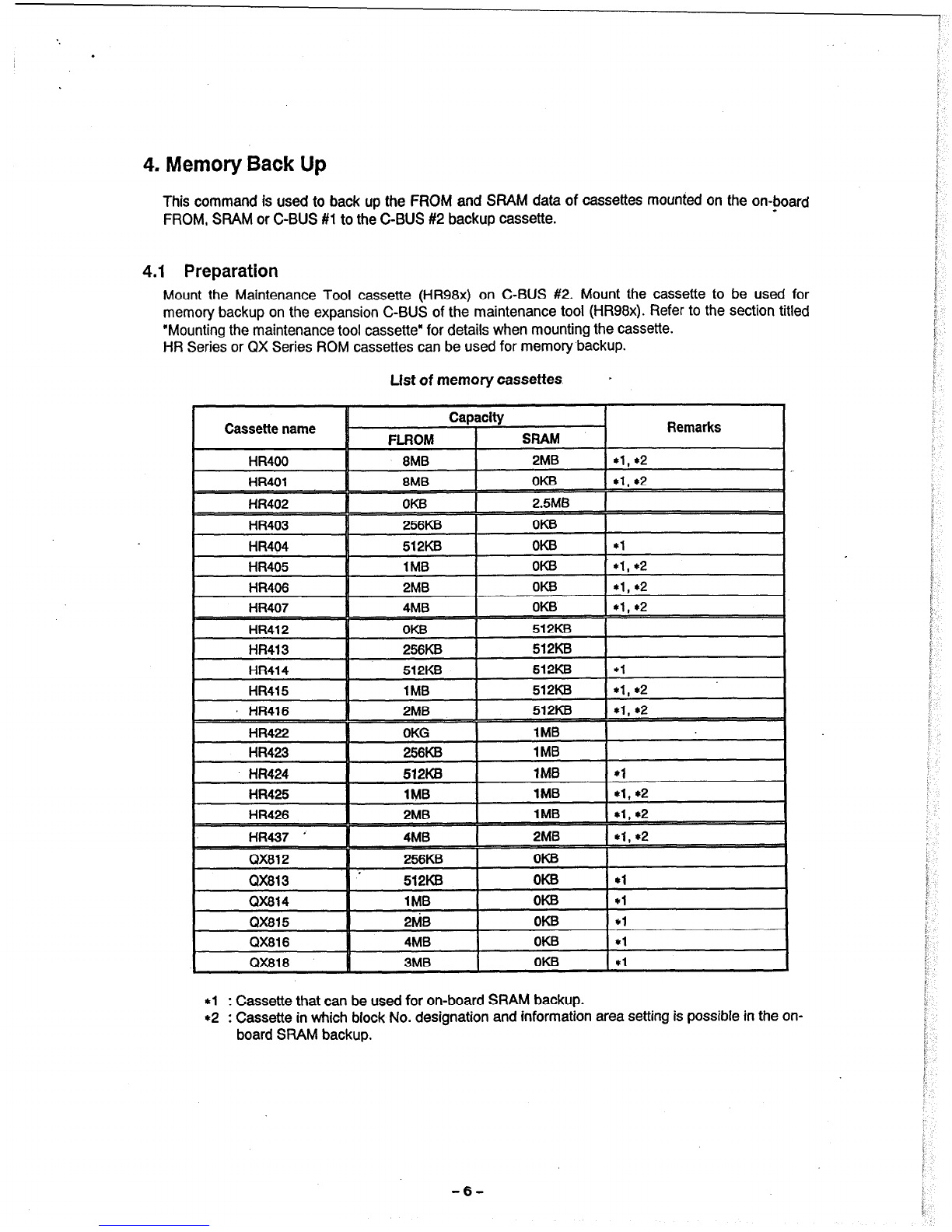

4. Memory Back Up .................................................................................................................................

4.1 Preparation ..................................................................................................................................

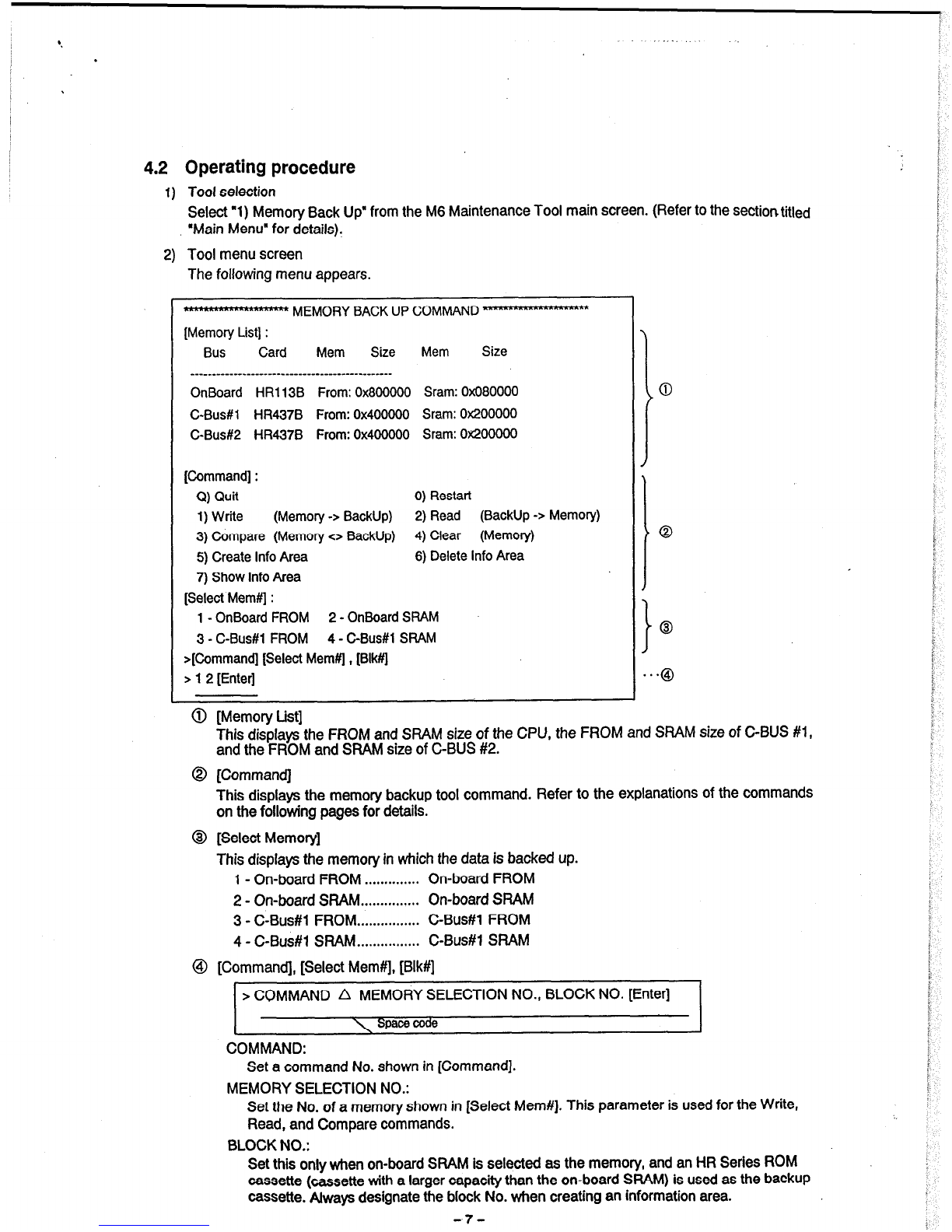

4.2 Operating procedure ...................................................................................................................

4.3 Explanation of commands ..........................................................................................................

4.4 Emr messages.. .........................................................................................................................

5. Serial Number and NC Typk, Unit type Set .....................................................................................

5.1 Preparation ..................................................................................................................................

5.2 Operating procedure ...................................................................................................................

6. Servo Spindle FNV Down Load.. ........................................................................................................

6.1 Preparation ..................................................................................................................................

6.2 Starting the tool ...................................................................................... .....................................

6.3 Operating proce&re in the normal mode.. .................................................................................

6.3.1 Initial screen .....................................................................................................................

6.3.2 Operation display.. ...........................................................................................................

6.3.3 Error information ..............................................................................................................

6.4 Operating procedure in the automatic firmware download mode .............................................

6.4.1 Operation proc&,re.. ......................................................................................................

6.4.2 List of error Nos ...............................................................................................................

6.5 Internal mnfigur&on of the M500 Maintenance Tool CaSSetk.. ...............................................

7. Command Line Mode ..........................................................................................................................

7.1 Outline ........................................................................................................................................

7.2 Memory map ....................................... .......................................................................................

7.3 l& of cammlds.. ......................................................................................................................

7.4 &mmand format.. ......................................................................................................................

7.5 Explanation of comma& ..........................................................................................................

7.5.1 End command line tool.. ..................................................................................................

7.5.2 Display help.. ....................................................................................................................

7.5.3 Display memory information ............................................................................................

7.5.4 Display memory.. .............................................................................................................

7.5.5 Modify memory.. ..............................................................................................................

7.5.6 Write FROM.. ...................................................................................................................

7.5.7 Erase FROM ...................................................................................................................

7.5.8 copy memory ..................................................................................................................

7.5.9 W&e memory.. ................................................................................................................

7.510 Clear memory.. ................................................................................................................

7.5.11 Compare memory.. ..........................................................................................................

7.5.12 meate a wpy of the M6 Maintenance Tool ....................................................................

8. Appendix 1 HyperTermlnal Starting Procedure ............................................................................

1

2

2

2

3

4

4

4

5

6

6

7

8

15

16

16

16

18

18 .

18

19

19

20

22

23

23

24

25

27

27

27

28

28

29

29

29

29

30

31

32

33

33

34

34

34

35

36