3

(13)Before starting to work on truck, hang "Do not

Operate" tag in the Operator's Compartment.

(14)Repairs, which require welding, should be per-

formed only with the benefit of the appropriate ref-

erence information and by personnel adequately

trained and knowledgeable in welding proce-

dures. Determine type of metal being welded and

select correct welding procedure and electrodes,

rods or wire to provide a weld metal strength

equivalent at least to that of parent metal.

(15)Do not damage wiring during removal operations.

Reinstall the wiring so it is not damaged nor will it

be damaged in operation by contacting sharp cor-

ners, or by rubbing against some object or hot

surface. Place wiring away from oil pipe.

(16)Be sure all protective devices including guards

and shields are properly installed and functioning

correctly before starting a repair. If a guard or

shield must be removed to perform the repair

work, use extra caution.

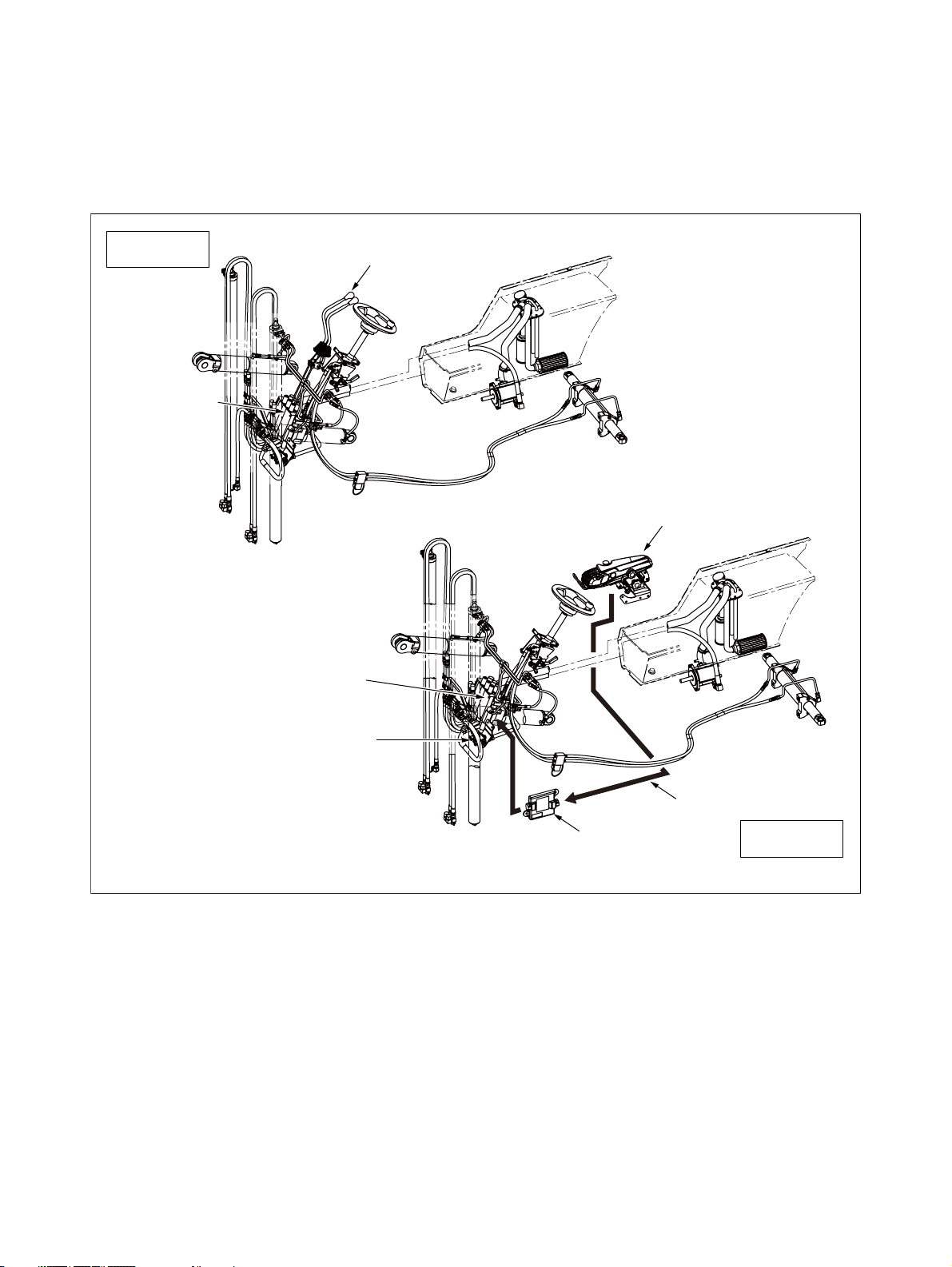

(17)Always support the mast and carriage to keep

carriage or attachments raised when maintenance

or repair work is performed, which requires the

mast in the raised position.

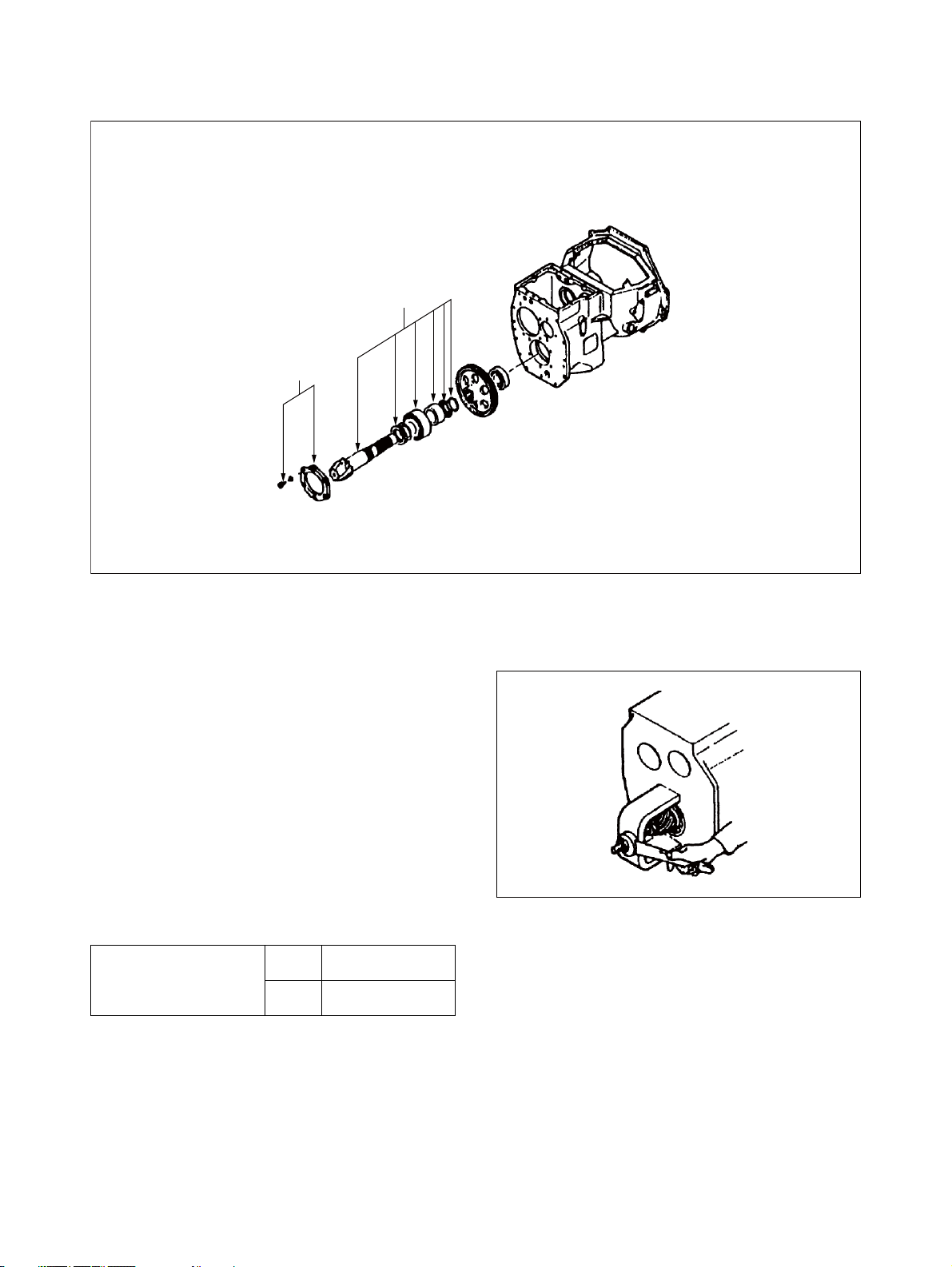

(18)Loose or damaged fuel, lubricant and hydraulic

lines, tubes and hoses could cause fires. Do not

bend or strike high pressure lines or install ones

which have been bent or damaged. Inspect lines,

tubes and hoses carefully. Do not check for leaks

with your hands. Pin hole (very small) leaks could

result in a high velocity oil stream that will be invis-

ible close to the hose. This oil could penetrate the

skin and cause personal injury. Use cardboard or

paper to locate pin hole leaks.

(19)Tighten connections to the correct torque. Make

sure that all heat shields, clamps and guards are

installed correctly to avoid excessive heat, vibra-

tion or rubbing against other parts during opera-

tion. Shields that protect against oil spray onto hot

exhaust components in event of a line, tube or

seal failure, must be installed correctly.

(20)Relieve all pressure in air, oil or water systems

before any lines, fittings or related items are dis-

connected or removed. Always make sure all

raised components are blocked correctly and be

alert for possible pressure when disconnecting

any device from a system that utilizes pressure.

(21)Do not operate a truck if any rotating part is dam-

aged or contacts any other part during operation.

Any high speed rotating component that has been

damaged or altered should be checked for bal-

ance before reusing.