INSTALLATION

- 2 -

2. INSTALLATION

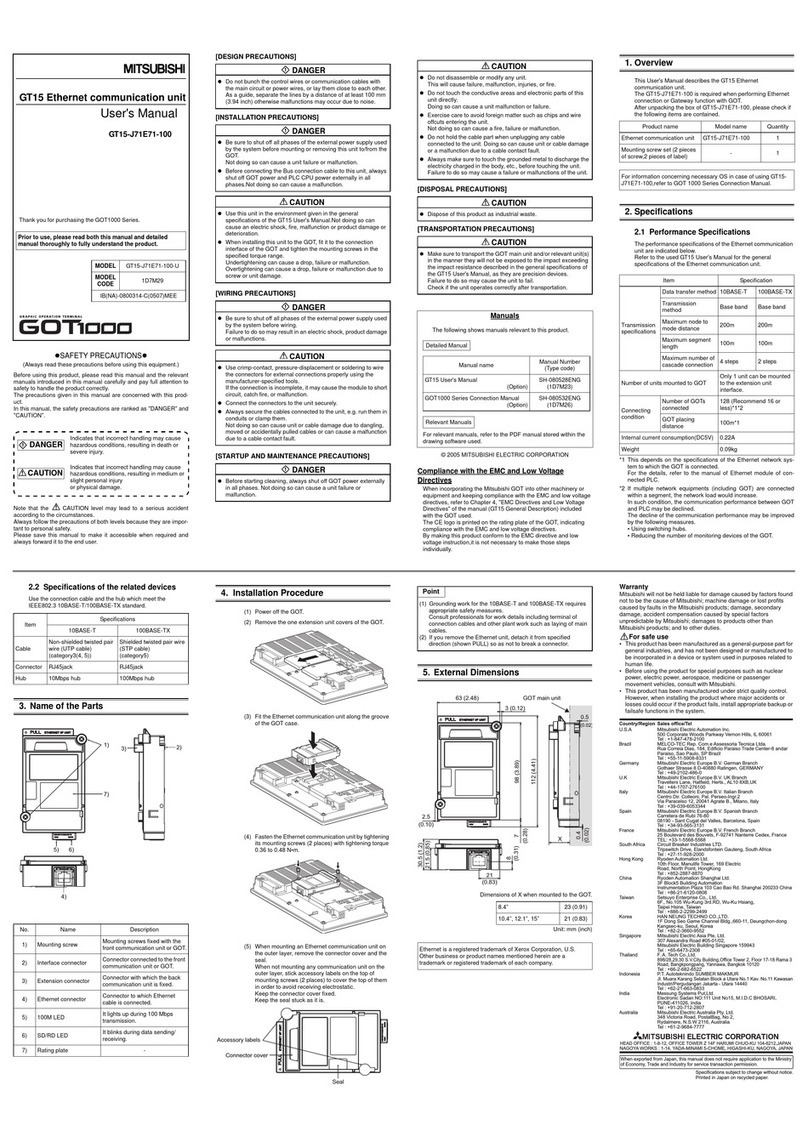

Remove the inverter cover and install the option unit using the following

procedure:

2.1. Pre-Installation Checks

(1) Check the inverter type.

This option unit may only be used with the FREQROL-A100E and A200E

series inverters and must not be used with any other series (e. g. A100,

A200, Z and F series). These models have a different option connector

to prevent connecting by mistake; however, if the user forces the

connector, the inverter may be damaged.

(2) Make sure that the inverter input power is off.

The inverter may be damaged if the option unit is installed with the input

power on. The inverter executes an initialization procedure at power on

that includes checking the option port. Adding the option later causes a

hardware conflict which may damage the inverter or option unit and

result in the alarm “E. CPU”.

(3) Ensure that the following accessories are supplied with the option unit:

Instruction Manual

Mounting Screws M3 x 14

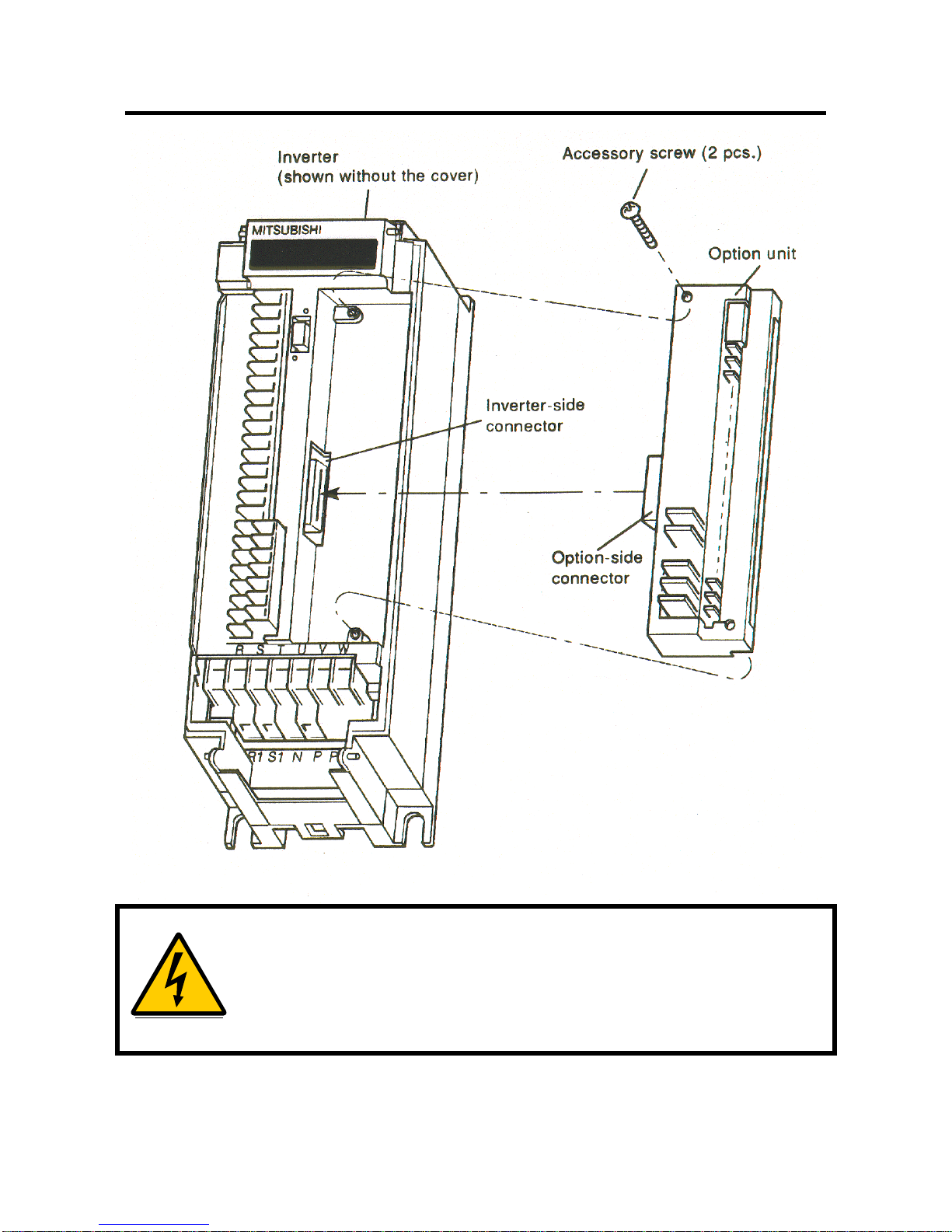

2.2. Installation Procedure

(1) Snugly insert the connector of the option unit into the connector of the

inverter.

(2) Securely fix the option unit to the inverter at the top and bottom with the

mounting screws. If the screw holes in the option unit do not line up

with the inverter mounting holes, check that the connectors have been

fitted correctly.