PRECAUTIONS BEFORE TEST RUN

PRECAUTIONS BEFORE REMOVE AND ELECTRIC WORK

WARNING

Always have the unit installed by Authorized Mitsubishi

Representative or similar professional.

Improper installation by the user could result in problems such as

water leakage, electric shock or fire.

Install the unit according to this Installation Manual.

If the unit is installed improperly, water leakage, electric shock or fire

may result.

Always use the designated cables and connect them properly.

When connecting the terminals, make sure that external forces

from the cable is not being conveyed to the terminal and then

tighten it securely.

Improper or loose connections could cause excessive heat or fire.

Only use Mitsubishi-approved accessories, such as an air

cleaner, humidifier or electric heater.

Always have such accessories installed by an Authorized Mitsubishi

Representative or similar professional. Improper installation by the

user may result in water leakage, electric shock or fire.

Have all electric work performed by a properly licensed electri-

cian. Electric work should be performed in strict adherence to

procedures to this Installation Manual. Always provide a dedi-

cated power supply.

If the capacity of the power supply is inadequate, it could result in

problems such electric shock or fire.

Never modify the unit and always have repairs performed by an

Authorized Mitsubishi Representative.

Improper repair could result in problems such water leakage, electric

shock or fire.

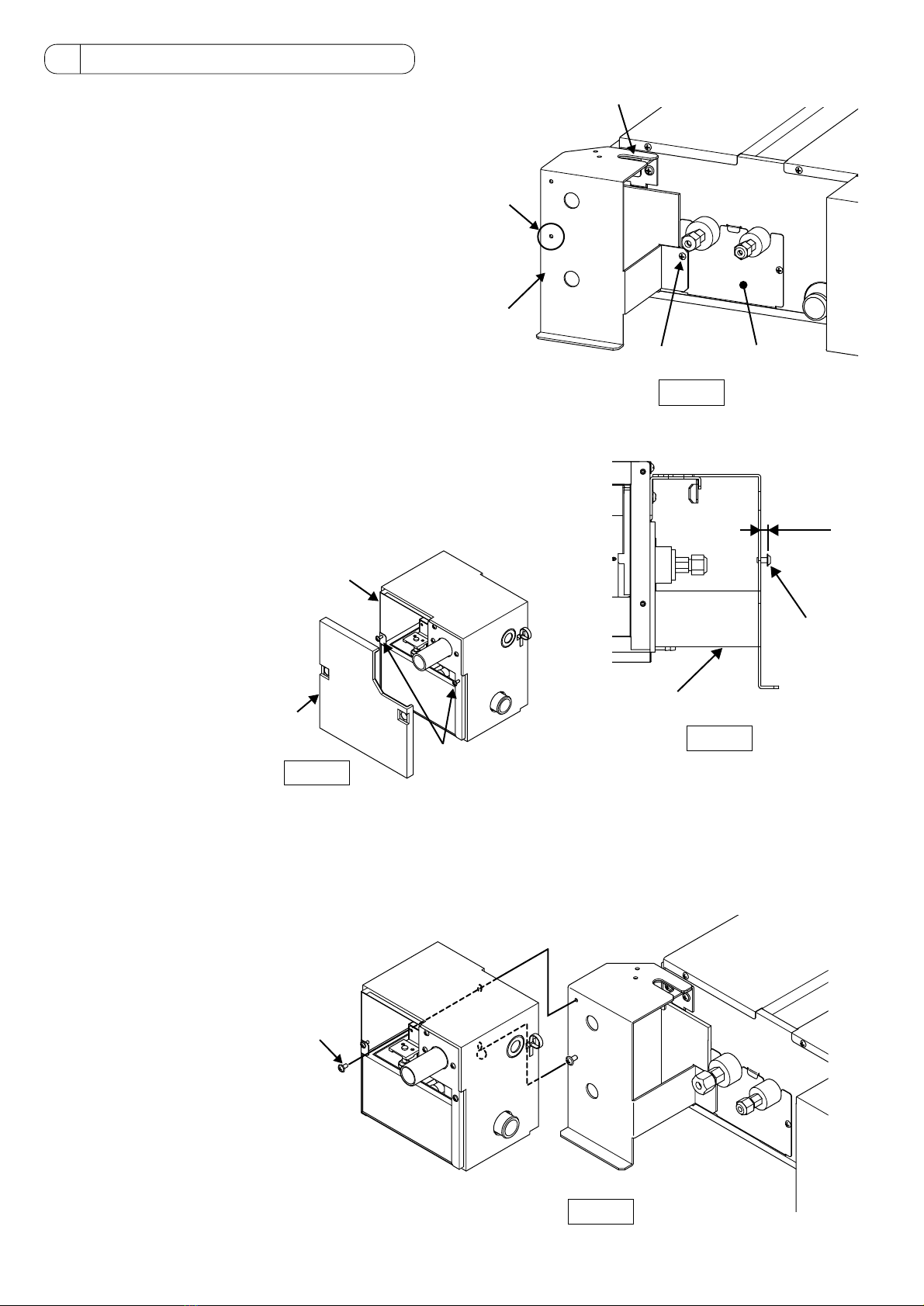

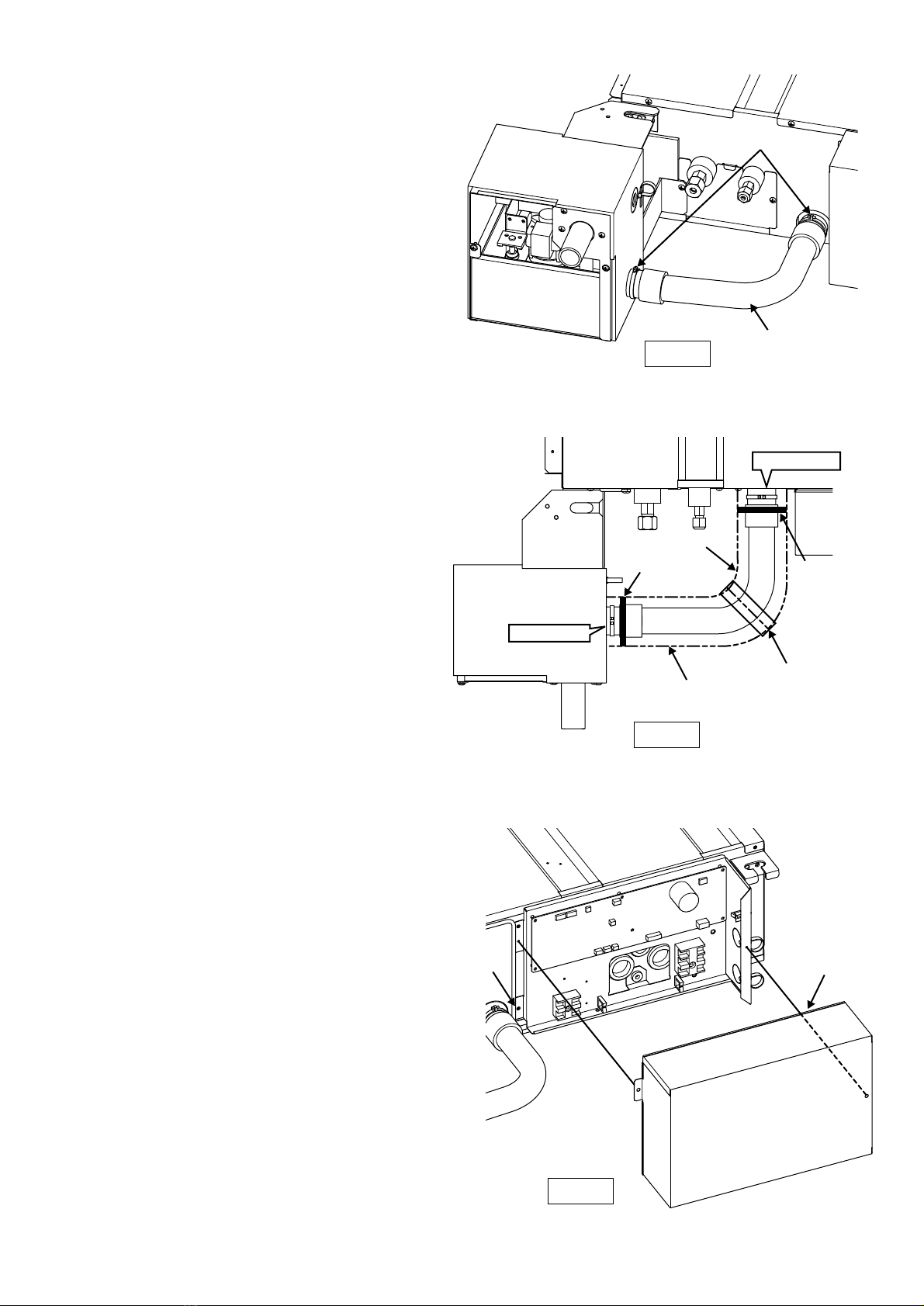

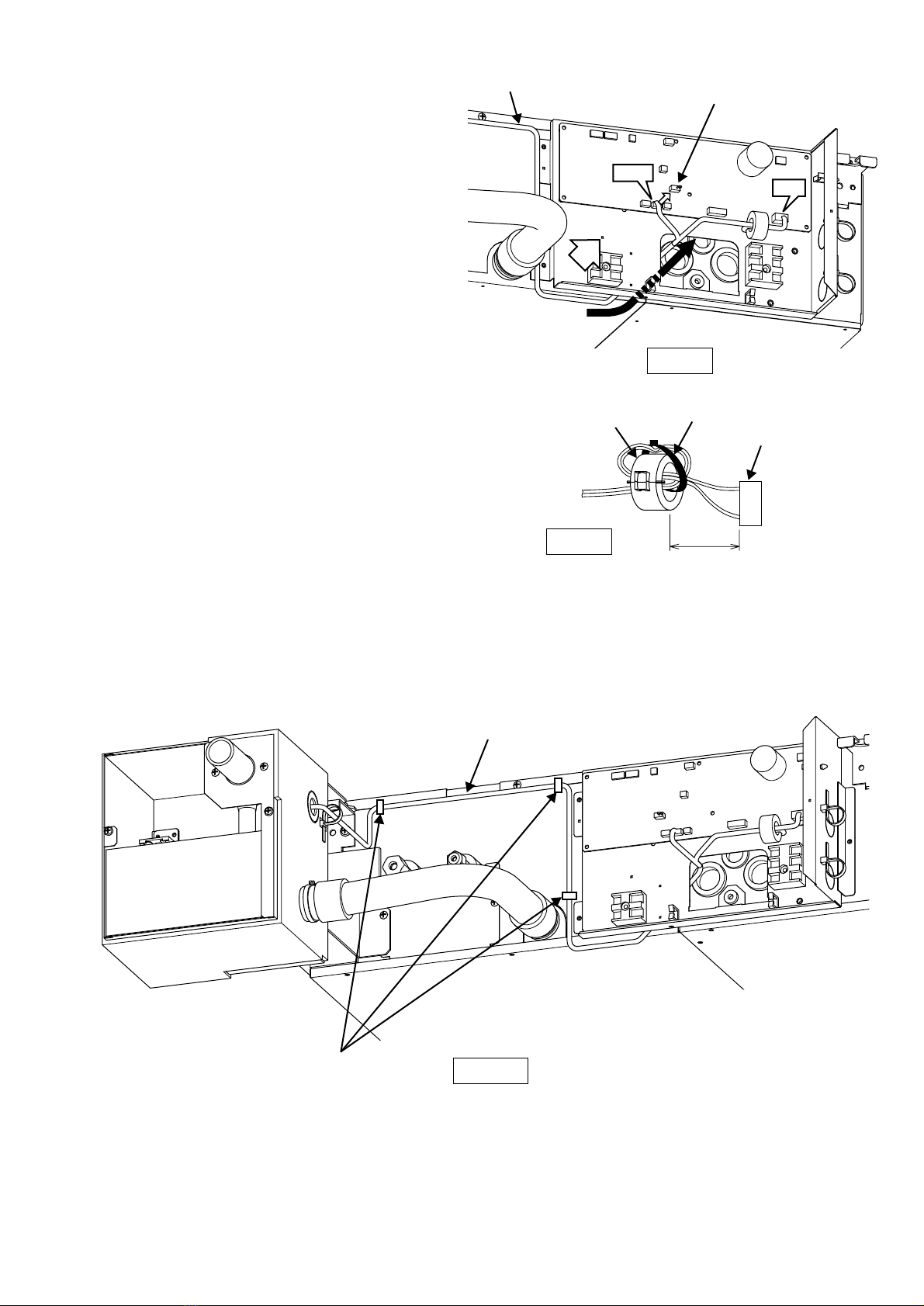

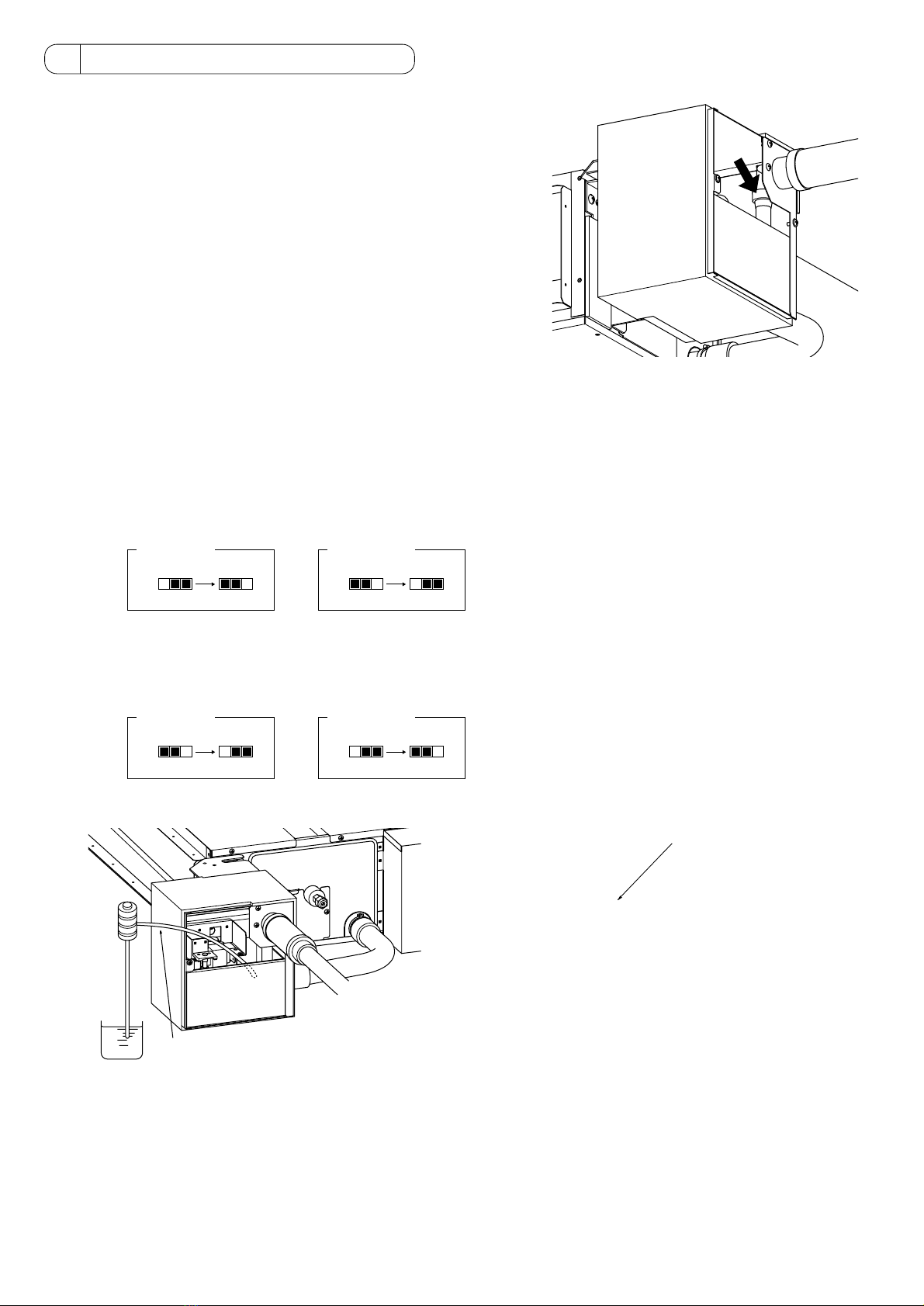

This installation manual contains only the description of how to install the Drain pump PAC-KE07DM-E. For information about how to wire and

how to install air conditioning units, see the installation manual for them.

For your safety, first be sure to read “ 1 Safety Precautions “ described below thoroughly and then install the Drain pump PAC-KE07DM-E

correctly.

This symbol denotes what could lead to serious injury or death if your misuse the PAC-KE07DM-E.

This symbol denotes what could lead to a personal injury or damage to your property if you misuse the PAC-KE07DM-E.

●The following two symbols are used to denote dangers that may be caused by incorrect use and their degree:

●After reading this installation manual, keep it in a place where the final user can see it anytime he or she wants to it.

When someone moves, repairs or uses the PAC-KE07DM-E, make sure that this manual is forwarded to the final user.

.WARNING

.CAUTION

Never use for special applications such as storing food, plants,

precision equipment or art.

The quality of these items may deteriorate.

Always provide adequate signal noise protection when

installing in facilities such as hospitals and communication sta-

tions.

Equipment at these facilities, such as inverters, in-house generators,

high-frequency medical equipment, two-way communication equip-

ment, may cause the air conditioner to operate improperly.

Conversely, the signal noise from the air conditioner may affect the

operation of medical equipment and two-way communication equip-

ment and this could interfere with the medical treatment being given

a patient or cause disturbances or interference in video broadcasting

equipment.

Never operate the air conditioner with the air filter removed.

Particles will enter into the air conditioner and cause damage.

Route wiring so that there is no tension.

Tension could cause the wire to break and this could result in exces-

sive heat or fire.

Dispose of packing materials properly.

Never use the unit in special environments.

Special environments with high concentrations of oil, steam or sulfu-

ric gases will reduce the performance of the air condition and cause

its parts to deteriorate.

Never turn off the power supply immediately after stopping the

unit.

Wait five minutes or more before turning off the power supply.

Turning off the power supply before that time could result in water

leakage or damage.

Never install the unit where run-off could result in damage.

If the humidity in the room exceeds 80% or if the drain becomes

clogged, water may drain off of the indoor unit. When the unit is used

for heating, there may be drainage from the outdoor unit. If required,

provide collector drain for the outdoor unit.

Use care when transporting the unit.

•Always use two or more people for lifting a product weight 20 kg. or

more.

•Some products are packaged with plastic wrapping bands. Never

use these for lifting or transporting the product.

•Never touch the fins on the heat exchanger. They are sharp and

could cause cuts.

•Never allow children to play with the plastic bags used for packag-

ing. Always tear them up when disposing. A child could suffocate

in these bags.

Never touch the switch with wet hands.

Electric shock could occur.

Never operate the air conditioner with the panel or guard

removed.

The hand could come in contact with rotating, hot or high-pressure

components. They could cause electrical shock or entanglement.

MITSUBISHI ELECTRIC

Air Conditioning For Building Application

Drain pump PAC-KE07DM-E

Installation Manual

WT05243X01

1 Safety Precautions

CAUTION

PRECAUTIONS BEFORE INSTALLATION