4

SECTION 4 - MAINTENANCE

PRIOR TO ANY DISASSEMBLY OR SERVICE

VERIFY THAT ALL REQUIREMENTS OF

STATUTORY REGULATIONS OR CODES ARE

MET AND THAT SPECIFIC SITE

REQUIREMENTS ETC. ARE SATISFIED.

Some inspections and maintenance tasks can be

performed with the pump 'in line' if complete

isolation, depressurising and purging procedures

have been completed. However for major

maintenance, it is recommended that the pump

be removed from the installation.

The following instructions regarding disassembly

and reassembly are relative to major

maintenance.

4.1 SPARE PARTS

When ordering spare parts, to ensure a minimum

delay and correct replacement to original

specification, always quote the pump serial

number which is located on the nameplate of the

pump.

Advise the name, cat # and quantity required.

Refer Drawing CMP082

Advise complete delivery instructions, transport

detail

4.2 PREPARATION FOR DISASSEMBLY

1. Obtain the appropriate work permit if

required.

2. Isolate the pump from liquids in suction and

discharge lines, depressurise and purge out

any toxic, flammable, corrosive or air-

hardening liquids.

3. Isolate power supply to motor.

4. Note driveshaft and porting orientation to

ensure correct reassembly.

5. Disconnect porting connections.

6. Remove pump from installation.

4.3 DISASSEMBLY

1. Remove lubrication harnesses and drain oil

from bearing housings (if oil lubricated).

2. Remove any plugs, vents etc. which may

hinder access to Bearing Housing nuts.

3. Remove Dustcaps from both ends of pump.

4. Unlock Lockwashers and Using a suitable

'C'

spanner, remove Shaft Locknuts (both

sides).

5. Loosen Sleeve Locknuts enough to just

clear the end of the sleeve. With a suitable

drift and hammer, sharply tap the faces of

the Sleeve Locknuts to release the Sleeves

from the Bearings.

6. Remove Bearing Housing Setscrews.

CAUTION

Place a support under Bearing Housings

which will allow Bearing Housings to be

removed from Pump without dropping as it

comes clear of the shaft where the locknut

thread begins. If the Bearing Housing does

not remain centred during removal the

Stationary Seal Face is likely to be chipped by

the thread on the shaft. Lubricate shaft before

removing Bearing Housing.

7. Screw two of the Bearing Housing

Setscrews (M20) into the extraction holes in

each Bearing Housing, tighten evenly to

remove bearing housing assembly. (It may

be necessary to tap the faces of the Sleeve

Locknuts again to fully release the Sleeves

from the Bearings)

8. Remove Sleeve Locknuts and remove

Sleeves from Bearings. If required, remove

Bearings from Bearing Housings.

9. Loosen the 6 grubscrews from each

Mechanical Seal Assembly. Carefully

remove Mechanical Seal Assemblies from

shaft.

10. Remove Cover setscrews, remove Cover

from inspection end.

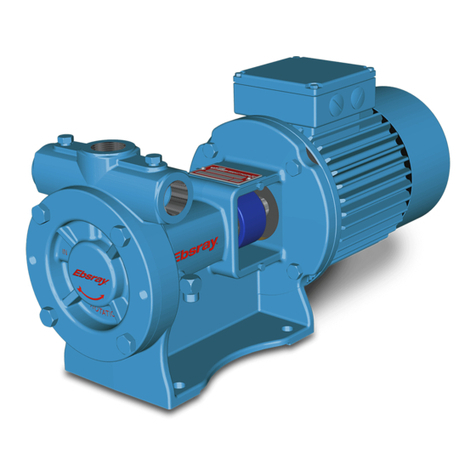

11. Place a 37mm diameter x 120 mm long bar

inside Liner (this is to support Rotor during

removal - see Figure 5)

12. Partially withdraw Rotor/Shaft Assembly

from inspection end far enough to allow

string or tape to be wrapped around the rotor

to retain the vanes and pushrods in position.

13. Remove Rotor/Shaft Assembly.

14. Release grubscrews and remove Seal

Spacers from Shaft.