3

1 SPECIFICATIONS AND MARKINGS

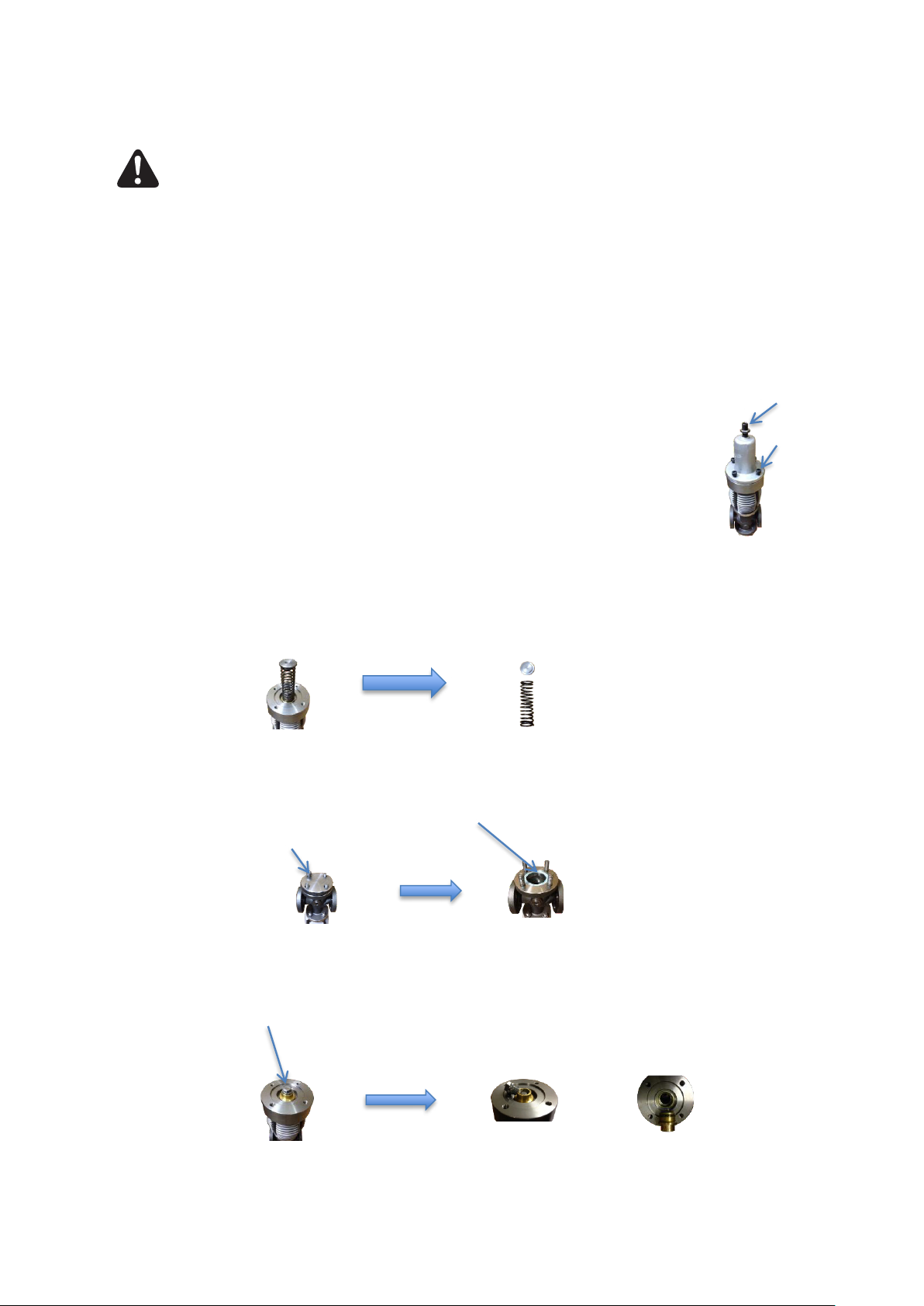

WARNING

Be sure not to use this product at higher pressures than the specified maximum allowable

pressure (PMA) or at temperatures

higher than the specified maximum allowable

temperature (TMA).

Main technical specification of the product:

(Check each item to avoid misuse of the product.)

PN16

Maximum allowable pressure (PMA): 1,6 MPa, 16 bar, 232 psig (@150°C, 302°F)

Maximum allowable temperature (TMA): 350°C, 662°F (@ 1,1 MPa, 11 bar, 160 psig)

Maximum operating (inlet) pressure (PMO): 1,5 MPa, 15 bar, 218 psig (@200°C, 392°F)

Maximum operating temperature (TMO): 350°C, 662°F (@ 1,1 MPa, 11 bar, 160 psig)

Adjustable Secondary (Outlet) Pressure: 0,05 to 1,6 MPa / 0,5 to 16,0 bar / 7.25 to 232 psig

PN25

Maximum allowable pressure (PMA): 2,5 MPa, 25 bar, 363 psig (@100°C, 212°F)

Maximum allowable temperature (TMA): 350°C, 662°F (@ 1,8 MPa, 18 bar, 261 psig)

Maximum operating (inlet) pressure (PMO): 2,2 MPa, 22 bar, 319 psig (@250°C, 482°F)

Maximum operating temperature (TMO): 350°C, 662°F (@ 1,8 MPa, 18 bar, 261 psig)

Adjustable Secondary (Outlet) Pressure: 0,05 to 1,6 MPa / 0,5 to 16,0 bar / 7.25 to 232 psig

(For lower or higher secondary pressure setting than indicated contact our office or local representative)

Maximum Pressure Reducing Ratio: 25 : 1

Minimum Differential Pressure: 0,05 MPa / 0,5 bar / 7.25 psi

Connection & Size: Flanged DIN-EN 1092-1 and ASME B16.5 –DN15 –DN200 (½” – 8”)

(For socket weld, butt-weld or screwed connections contact our office or local representative)

Flow direction: Shown by an arrow.

Body material: Ductile cast iron 0.7040

Check the Pressure-Temperature Rating of the product.

Don’t use it beyond the pressure and temperature limits of the table !!

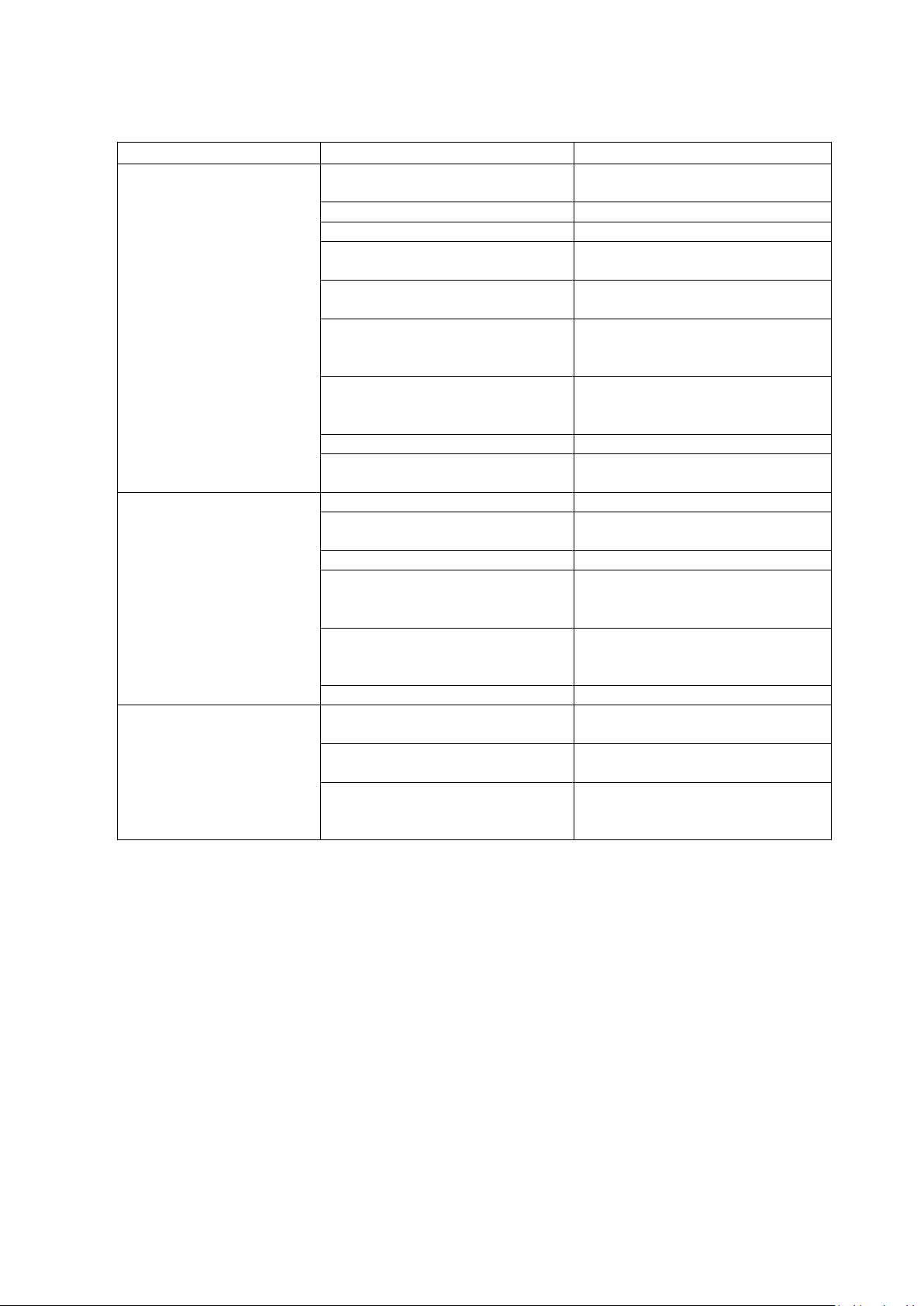

PN Body

material

Temperature °C

-10 …+50 100 150 200 250 300 350 400 450 500 530

16 0.7040 1,6 1,6 1,6 1,5 1,4 1,3 1,1

25 0.7040 2,5 2,5 2,4 2,3 2,2 2,0 1,8

40

63

100

1