8

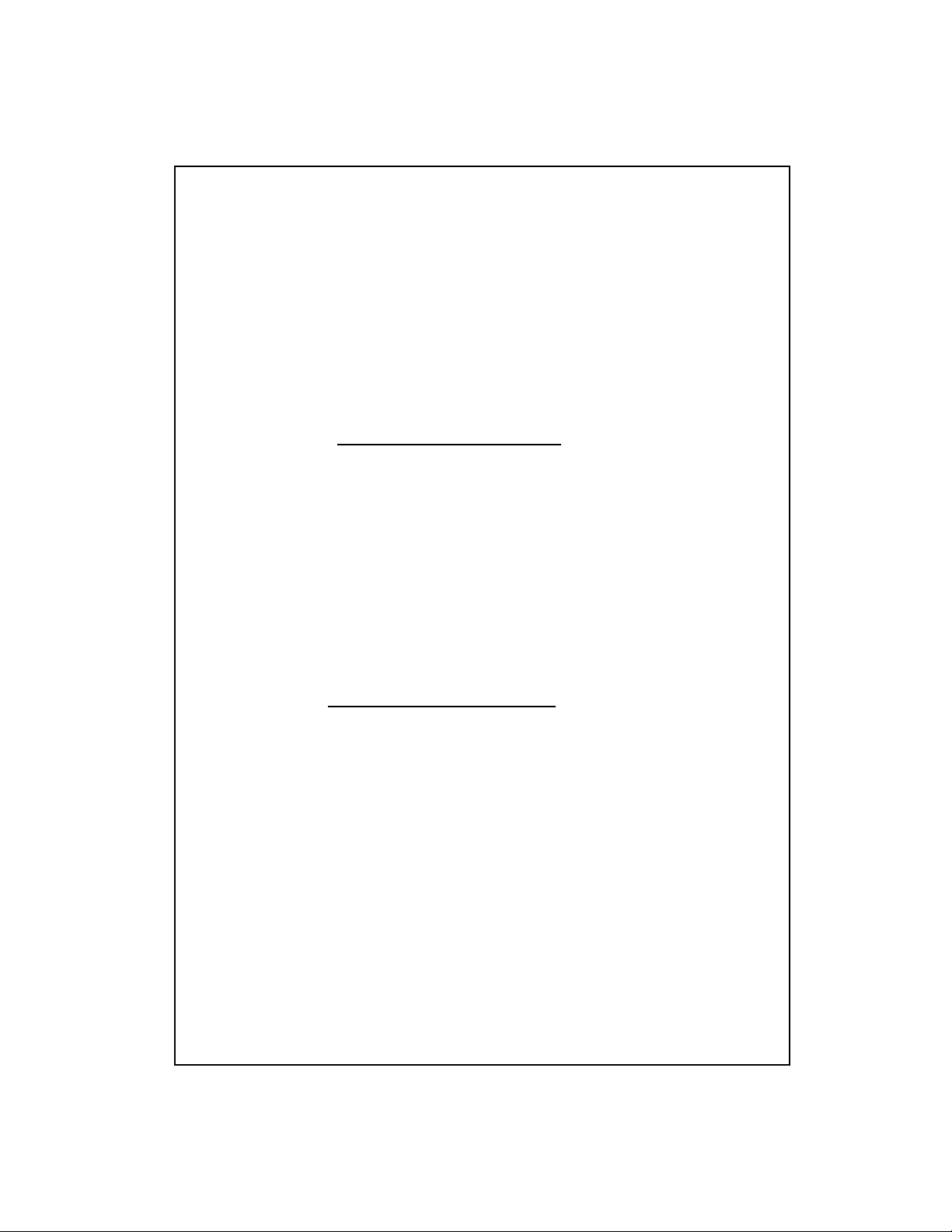

Meteor Loader Blower Decal Location

6 5

4

3

1

2

7

5

4

3

1

Folder

S:\Solidworks\Solidworks_Elo\Snowblower\LoaderBlower\33365 Hyd Power Pack.SLDASM

DWG. NO.

REV

Model

SCALE 1:24

SHEET 6 OF6

DATE DRAWN

MATERIAL

33365 Hyd Power Pack

October-01-12 10:56:13 AM

DESCRIPTION

Hyd Power Pack Assy

S:\Solidworks\Solidworks_Elo\Snowblower\LoaderBlower\

Weight(lbs.)

0

Width

Height

Length

0 0

535.03

0

Blank Size

Unit of Measure

ITEM ID.

33365

Config ID

33365

DIMENSIONS ARE IN INCHES

TOLERANCES NON SPECIFIED:

FRACTIONAL

1/64

BEND

1.0

TWO PLACE DECIMAL

0.01"

THREE PLACE DECIMAL

0.002"

Notes

DO NOT SCALE DRAWING

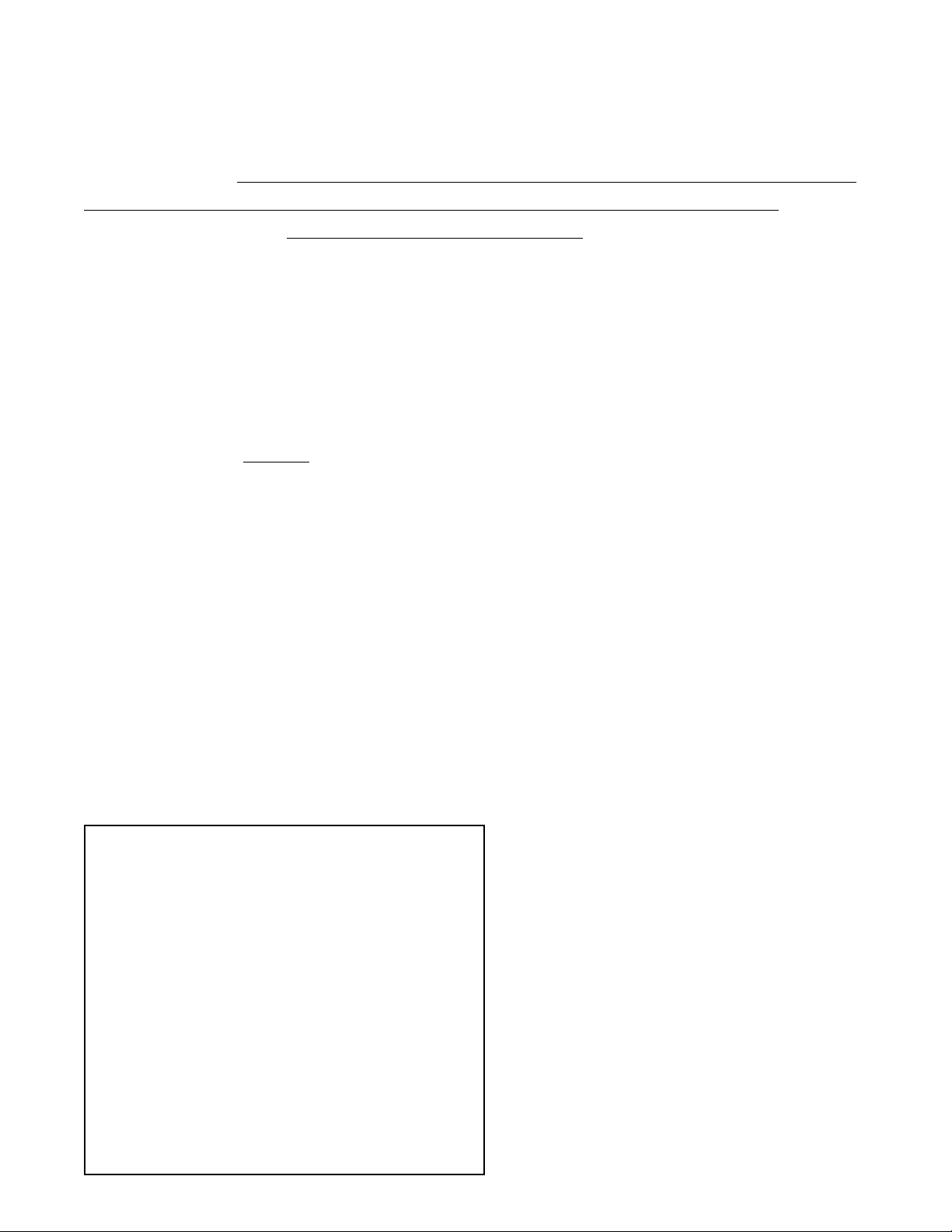

Meteor Loader Blower Decals Power Pack Decals

1- Meteor small decal 2 pieces

1

11

12

10

2

4

5

6 7 8 9

3

5

4

3

1

Folder

S:\Solidworks\Solidworks_Elo\Snowblower\LoaderBlower\76 Blower\33886.SLDASM

DWG. NO.

REV

Model

SCALE 1:48

SHEET 2 OF2

DATE DRAWN

MATERIAL

33886

June-08-17 4:48:03 PM

DESCRIPTION

76 Loader Blower Assy

S:\Solidworks\Solidworks_Elo\Snowblower\LoaderBlower\76 Blower\

Weight(lbs.)

0

Width

Height Length

0 0

1013.79

0

Blank Size

Unit of Measure

ITEM ID.

33886

Config ID

33886

DIMENSIONS ARE IN INCHES

TOLERANCES NON SPECIFIED:

FRACTIONAL

1/64

BEND

1.0

TWO PLACE DECIMAL

0.01"

THREE PLACE DECIMAL

0.002"

Notes

DO NOT SCALE DRAWING

2- 244 Avoid uid escaping under

pressure. Consult technical manual for

service procedures. 1 piece

3- Serial number plate 1 piece

4- 213 Do not open or remove safety

shields while engine is running. 1 piece

5- 224 Keep safe distance from this

machine. 1 piece

6- Chute decal. 2 pieces

7- SmallMKMartin Made in Canada. 1pc

8- 226 Shut off engine and remove key

before performing maintenance or repair

work. 1 piece

9- F9 Read operators manual

1 piece

10- 212 Do not open or remove safety

shields while engine is running.

1 piece

11- Grease decal. 2 pieces

12- 236 Stay clear of rotating auger

2 pieces

1- SmallMKMartin

Made in Canada 1 piece

2- Decal SMV, slow moving

vehicle. 1 piece

3- 226 Shut off engine and

remove key before performing

maintenance work. 1 piece

4- F9 Read operators manual

1 piece

5- 207 Stay clear of draft link

lifting range while operating

rockshaft controls. 1 piece

6- 220 Do not open or remove

safety shields while engine is

running. 1 piece

7-244 Avoid uid escaping under

pressure. Consult manual for

service procedures. 1 piece