SM 1690

page 6 of 18 File: SM1690_r5eng - Dec. 2013 - Technical note: SM1690

SM 1690 SM 1280

SM 1690

File: SM1690_r5eng - Dec. 2013 - Technical note: SM1690 page 7 of 18

Equipment installation

The SM1690x cannot operate on a bench: it must be installed

into a proper cabinet like a commercial 19” standard enclo-

sure.

The equipment is intended for industrial use only, not for

laboratory use, and user must respect the wiring norms and

prescriptions as described into next paragraph (“Wiring

instruction”).

The equipment cannot operate cantilevered, it must be safely

fixed inside a cabinet by means of screws on the front panel

(which is provided with 4 holes) and supported by means of a

proper frame on the bottom for, at least, 3/4 of the total depth.

Usually two “L” shaped supports on each side of the equip-

ment, having a dimension of mm 10(h) x 30(l) x 2 (thick) are

suitable for that purpose.

The rear side of the equipment must be protected by a fixed

panel which can be removed only by means of tools or by a

door with security micro-switch: when the door is opened the

micro-switch must shut-off the main line. This safety precau-

tions must be taken to avoid operations on rear fuses or on

connectors while the unit is still powered.

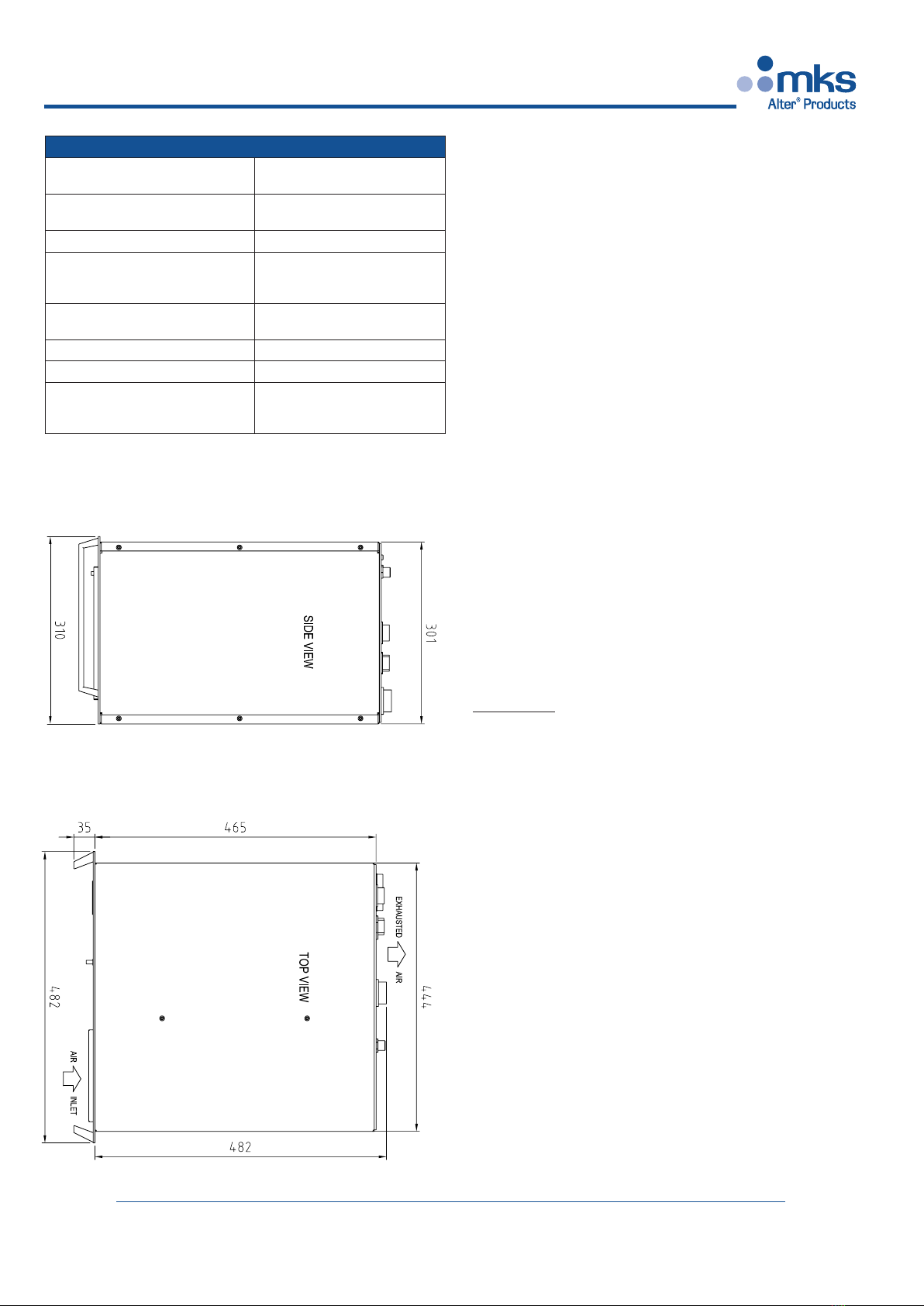

Special attention must be taken on designing the cooling air

flow in case of stacking several units into the same cabinet.

Note that each equipment has its own fan which intake approx

200 m³/h: the outlet of the exhaust air is on rear panel, the

inlets on the right side (looking at front).

When designing a board to house several units we recommend

to adopt the following design criteria:

1. use a standard 19” wide enclosure with a depth of 800 mm

(32”);

2. allow free intake of the cooling air from the front of the

cabinet and exhaust air from back panel throu the top of the

cabinet or the back side;

3. in case of ambient air with high degree of dust and moisture,

install a proper air conditioner; if you cannot do this, then you

have to use suitable air filters and instruct the user about their

cleaning;

4. provide a separation between the air intake duct and the air

outlets, in order to avoid air-recyrculating;

Handling instructions

The equipment weight is 40 kg (88 lbs). Always lift from the

bottom and use an adeguate rugged support to avoid personal

injury and damage to equipment itself.

In case of shipping, package with the original package or use

a wooden case and a proper filler: movement of the equipment

inside the package must be avoided.

Warning for handling: use handles only for help during

installation. Never use handles to lift the rack: the handles

don’t withstand the off-center weight of the rack!

To lift always lean the rack over a proper supporting base.

Wiring instructions

The SM1690x must be installed and serviced only by quali-

fied personnel acquainted with the regulations covering the

application. For safety operations the following rules must be

adopted:

I) The equipment must be grounded through the connector

#1 using pin 4 (see the wiring diagram at page 13).

II) Connect the ground screw on panel rear (indicated by

“ground” symbol) directly to the remote microwave generator

head by a separate yellow/green wire gauge 2.5 mm².

III) The main supply must be provided through connector

#1: connect phases according to schematic at page 11, the

connector’s pins can house wires with gauge up to 10 mm².

Warning: this connector is not intended for live insertion

of the unit: an external tripolar breaker must always

be provided, and the unit must be switched off before

inserting/unplugging of the connector.

IV) The connector #4, with 14 pins, brings the head’s signals

to the equipment. Use wires with max gauge of 1.5 mm²,

refer to wiring diagram at page 12.

V) The connector #5 is the high voltage output and must be

connected to magnetron’s cathode, usually marked with the

symbol “FA” on the magnetron’s teminal. The voltage value

is near -9 kV .Use a proper insulated cable with working vol-

tage >10 kVdc and minimum gauge of 0.25 mm²; protect the

wire with sheating (armoured if appropriate).

Assemble the wire into plug according to professional rules.

The reliability of the equipment starts from the h.v. connec-

tions.

ALTER may supply the HV cable with lenght on request.

VI) The connector #3 provides the power supply for the

filament transformer (usually located near the magnetron), the

magnetron fan and a warning lamp. Use wires wih max gauge

1.5 mm². Refer to wiring diagram at page 12;

VII) The “D” type female connector #6 has 25 pins and brings

the I/O signals to the equipment. Refer to wiring diagram at

page 13.

VIII) The CONN# 8 has a type of socket that depends on the

fieldbus interface:

- RJ 45 on Ethernet-Modbus TCP

- 9 pin “D” on CANopen/Profibus

IX) The “D” type female connector RS232 has 9 pins and it’s

a standard serial port, that can be used to upgrade of the sof-

tware from a PC, or to retrive internal data through FrontPa-

nel GUI. Look the pin-out at page 11.

X) The user must provide external cut-off device, to protect

the SM1690x from short-citcuit and thermal runaway; this

external protection device must also allow to switch-off the

main line for maintenance operations.

XI) The external circuit breaker must be a 3-poles current

limiter breaker and must comply the norm EN61010-1.

XII) The external circuit breaker must be in close proximity

of the equipment and within easy reach of the operator.