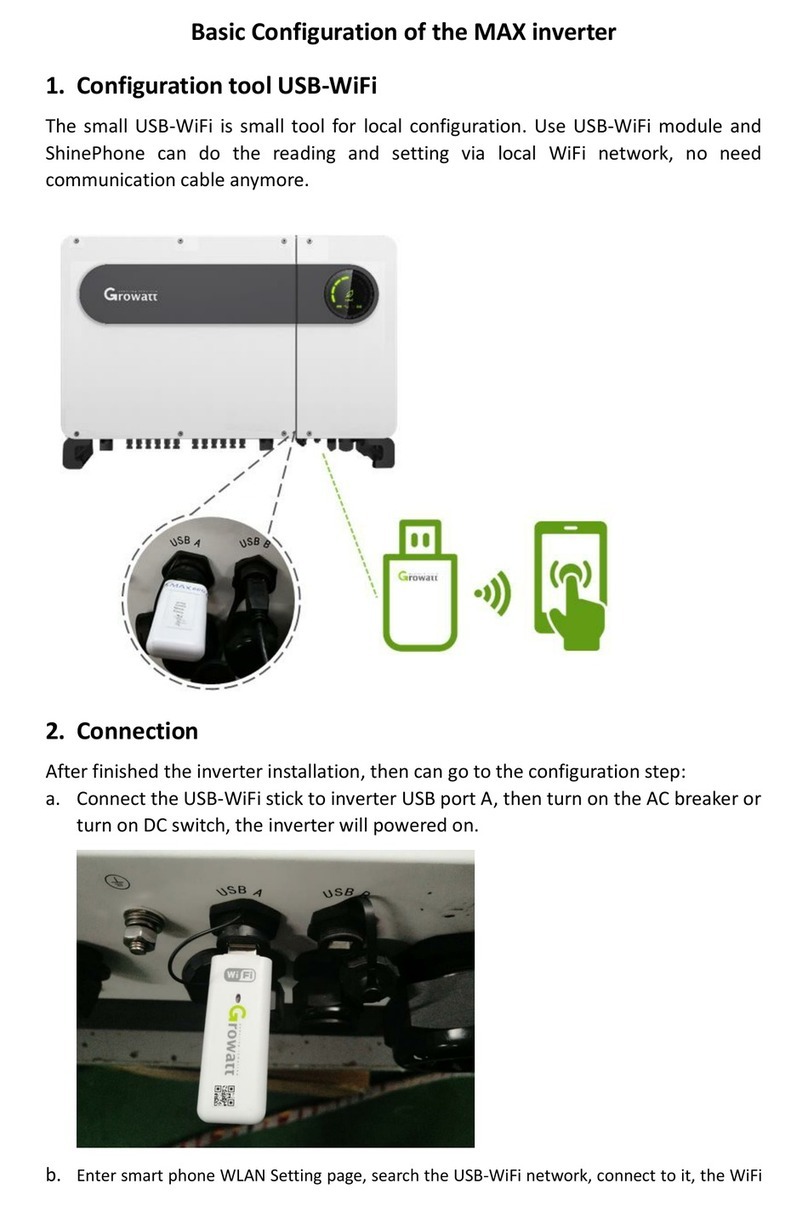

1 Overview

1.1 Product Overview

This manual is aimed at providing sufficient information and installing instruction for

consumers buying Shenzhen Growatt New Energy Technology Co.,Ltd (short as Growatt)

MAX Series solar inverters. Please read this manual carefully before using the MAX series

inverters and store the manual in a reachable place for an authorized technician. No

further notice if there is any change in this manual.

1.2 Applicable Personnel

Only qualified electrical technicians are allowed to install MAX series inverter. With

reading through this manual and following all the precautions, qualified electrical

technician can properly install MAX serial inverter, finish trouble shooting and

communication settings.

If there is any problem during the installation, the installer can either log on

www.ginverter.com and leave a message or call consumer service hotline +86 755

27471942.

2 Safety Precautions

2.1 Safety Overview

1>Before installation please make sure reading through this manual, any damage caused

by improper installation, Growatt reserve the right to disclaim any warranty.

2>All the operations and connections must be done by trained qualified electrical

technician.

3>During installation except for terminals, do not touch any inside part of the inverter.

4>All the electrical connections must meet local country's safety regulations.

5>If you need maintenance for this inverter, please contact our local authorized

installing and maintenance technician.

6>You must get the local power supplier's permit before connecting this inverter to the

grid.

H a n d l e P r o c e s s:

Installation:

Electrical Connections:

Maintenance and replacement:

•The inverter is heavy,please treat with care while handling,in case of

crushing injury.

•

cause by improper installation,Growatt reserve the right to disclaim

any warranty.

Before installation,please read through this manual,any damage

•Ensure that the MAX is not connected to a power supply and is not

power on before installation.

•

at "OFF” also disconnect AC switch, otherwise the high voltage from

inverter may cause life risk.

•Only trained authorized electrical technician can do the electric

connection also please follow the connection procedures in this

manual along with local country's regulations.

•High voltage may cause electric shocks and serious injury please

do not touch the inverter.

•Please do not store inverter in area with flammable and explosive

material.

Before electrical connection, please ensure the inverter DC switch is

•

accurately follow this manual.

•Please disconnect the DC and AC switch for at least five minutes, all

the operations should be carried after power disconnection.

•If there is PV isolation low alarm, the inverter case may be ungrounded,

please do not touch the inverter case.

•High voltage of inverter may result in electric shock.

Must be installed by trained and authorized electrical technician and

•Each inverter must install one AC breaker; AC breaker is forbidden to

share with other inverters.

•It is forbidden to add load between inverter and breaker.

•If the cable is thick, after tightening the cable do not shake it and

ensure the cable is well-connected and then start the inverter.Loose

connection may cause overheat.

•Before connecting between PV panels and inverter please ensure the

positive and negative poles are correct connected.

•

•Do not use air pump to clean the fans, cause it may damage the fans.

For better cooling purpose, please regularly clean the fans.

1

2

•Please follow this installation manual as installation condition

environment,space and so on.

• P l e a s e i n s t a l l t h e i n v e r t e r i n a d r y a n d v e n t i l a t e d

environment,otherwise may affect the performance of the inverter.

•Please follow the installation procedures in this manual.

WARNING

WARNING

DANGER

DANGER

DANGER

NOTICE

WARNING

WARNING