5

MOBIUSTRIMMER.COM

SAFETY INSTRUCTIONS

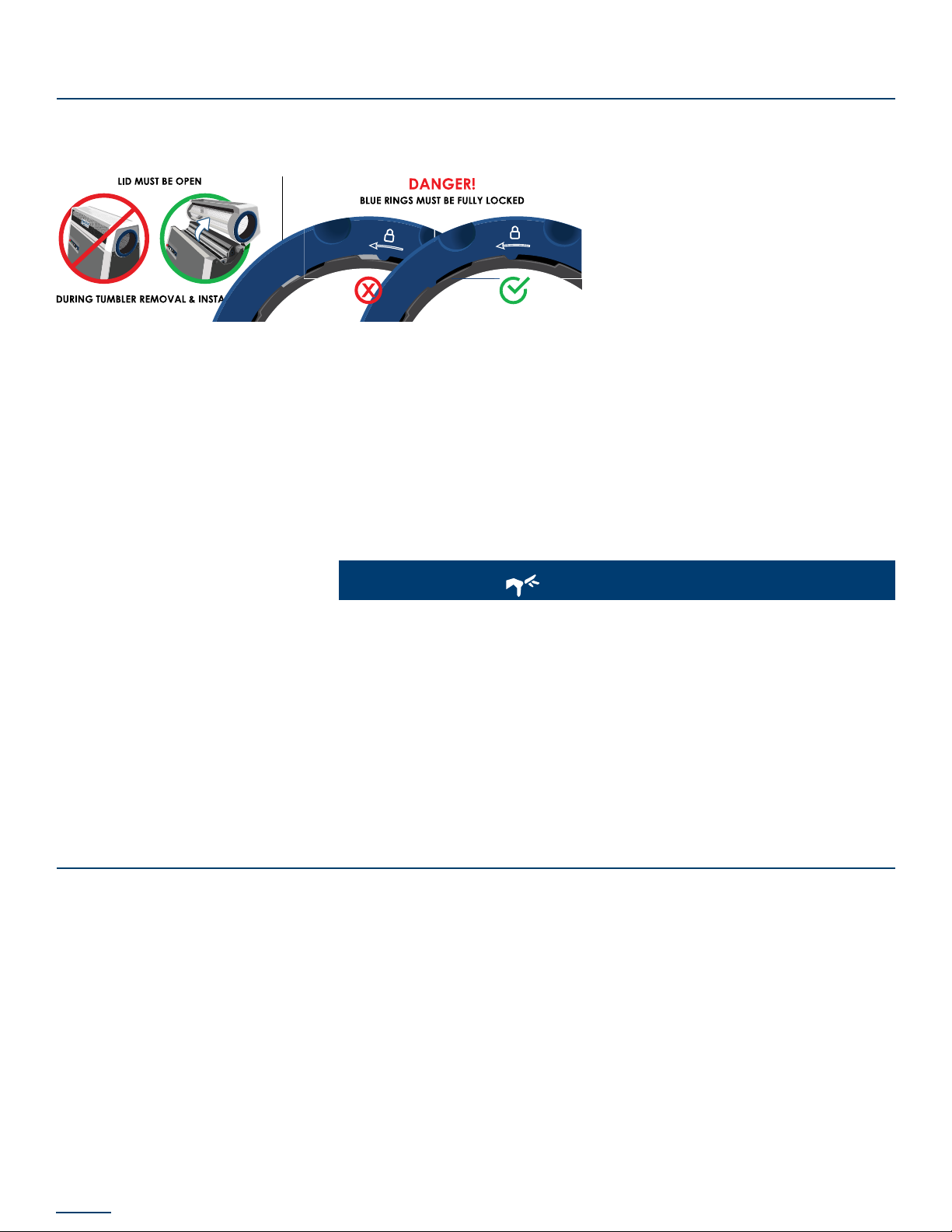

To ensure operator safety while in use, this device includes decaling, guarding, and other safety features.

Operators are encouraged to use caution and best judgment when using equipment. Equipment

should be serviced when required.

To avoid possible damage to the machine and risk of injury to the operator, consult with an ETEROS

TECHNOLOGIES representative to answer any questions.

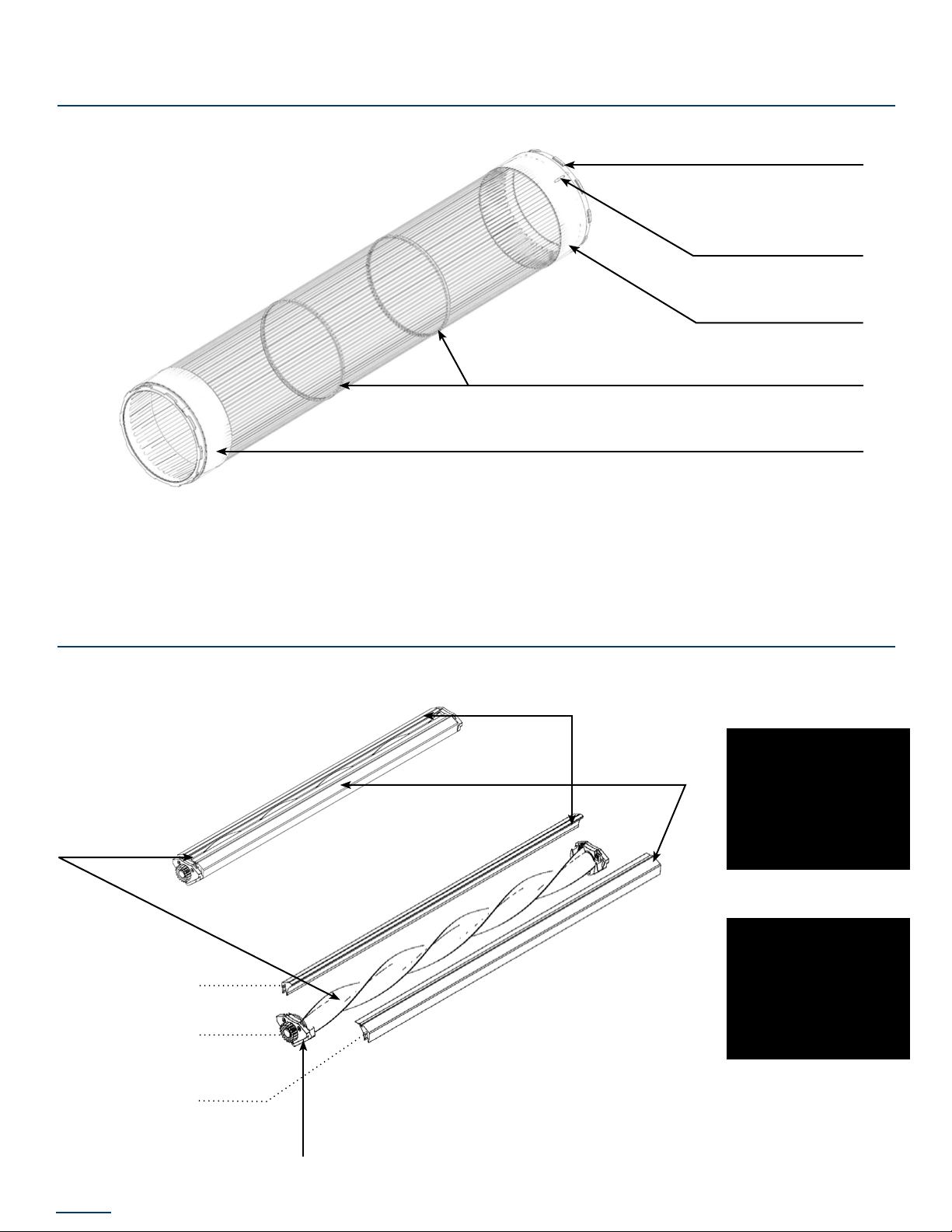

This document refers to the ETEROS TECHNOLOGIES product trimming machine as the M108S. Since this

machine has moving blade components, special safety precautions must be observed to reduce the

risk of personal injury. Careless or improper use may cause serious or even fatal injury. Please read and

understand these precautions thoroughly before using the machine.

All operators must read and understand this User Guide and be trained in safe operation and use of

the M108S. We recommend the owner of this equipment develop a standard operating procedure

specic to each worksite to address any local hazards or other conditions not outlined in this User

Guide. The M108S must be inspected regularly for damage, component failure, and wear. Results of

inspection activity should be documented.

ETEROS TECHNOLOGIES makes every effort to ensure the M108S is compliant with all current safety

standards. It is the responsibility of the owner to ensure all municipal, provincial, state, county, territorial,

and federal codes, regulations and standards have been met in each working location. Do not lend

or rent your machine without providing the User Guide. A rst-time operator should receive practical

instruction before using the machine.

This machine is not to be used for any purpose other than those expressly stated in the User Guide,

advertising literature, or other ETEROS TECHNOLOGIES written material pertaining to the M108S.

Operators must be in good physical condition and mental health to operate this device. Under no

circumstances should the device be operated by anyone under the inuence of any substance,

including drugs or alcohol, which might impair vision, dexterity, or judgment. Do not operate the M108S

when fatigued. Be alert. If tired while operating the device, take a break. Fatigue may result in loss

of control. Working with any equipment can be strenuous. If you have any condition that might be

aggravated by strenuous work, check with your doctor before operating the device.

DISCLAIMER

ETEROS TECHNOLOGIES recognizes that the M108S is a purpose-built machine for processing cannabis

and hemp by licensed producers. Please check all municipal, provincial/state, and federal laws and

regulations before using the M108S. ETEROS TECHNOLOGIES does not promote or condone the use of

processing equipment in any way that may be deemed illegal.

It is not the responsibility of ETEROS TECHNOLOGIES to conrm alternative equipment applications.