3

parts in dishwashing liquid and warm water to remove traces of mold release agent and body oils your

fingers may deposit. Allow the parts to dry thoroughly before applying primer and painting. Try to avoid

painting, whenever possible, surfaces to be glued together, or locating pins that insert into holes. Due

to the metal casting process used and shipping; some deformed parts may be received, or filled in

holes that will have to be drilled. Parts can be straightened by gently and slowly reforming with your

fingers. Check with the plans and photographs to verify the reforming of the part(s); every effort was

made to reproduce the parts accurately but some deforming may occur during de-molding or shipping

due to the weight of the parts themselves.

Photo Etched Parts: An etched aluminum sheet of parts is included in the kit. Care must be used to

cut these parts from the carrier sheet using the tip of a hobby knife blade on a hard surface like steel or

use small scissors/snips. Cut tabs will need to be filed smooth using a fine needle file. The “Eindecker

E-IV” on the aluminum sheet can be used to make a nameplate if desired.

Glues: Super glues, such as Jet, Flash, or Zap, produce quick adhesion. For most applications, the

medium viscosity, gap-filling variety is best allowing a little time for final positioning. The thin type is

recommended for filling a narrow crack, wicking into laminated tight joints and seizing thread ends to

make “needle” points. These instructions will refer to super glues as CA (cyanoacrylite). For Basswood

and Plywood it is best to use Yellow Wood glue like Titebond which is easier to sand than CA which

hardens the plywood. Epoxy glue is highly recommended for gluing metal cast engine parts some of

which are heavy. The five minute setting type is sufficient for this build. Scoring mating metal joint

surfaces with the tip of a hobby knife in a cross hatch pattern will increase the strength of the glue

joints. Excess glue can be cleaned carefully with acetone on a Q-tip, but take care not to loosen the

glued joint.

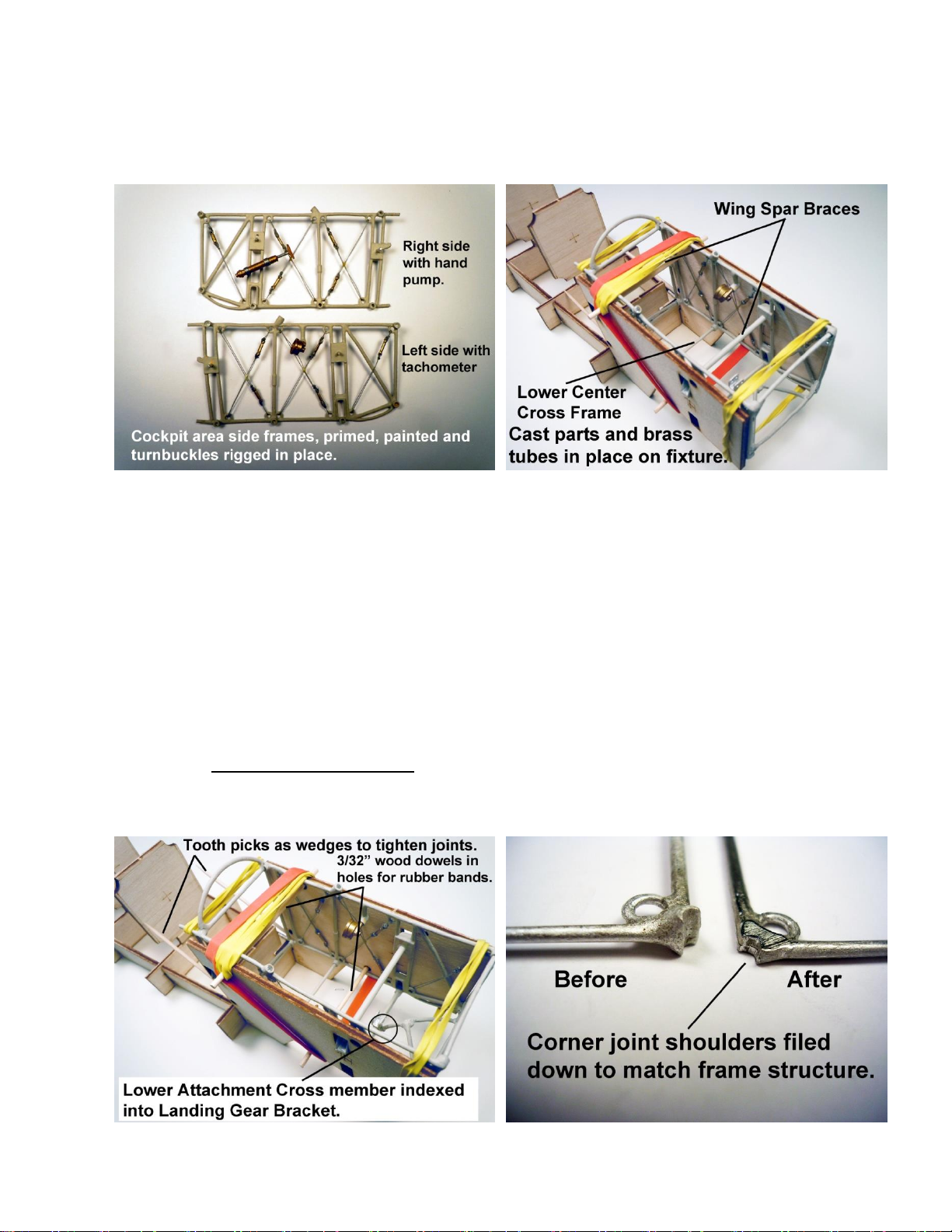

Building Tips and Suggestions before Starting to Build

Read assembly instructions, study the pictures and review the plans to understand and familiarize

yourself with various parts and components and how they relate to each other.

Check parts list to make sure you have all the kit parts listed.

Verify that you have all the tools and materials needed to start the build. See the materials list and

suggested tool list on the next page. A variety of rubber bands is essential to assemble the fuselage.

Try to follow the suggested build sequence outlined in the assembly instructions.

Pay attention to steps that are BOLD face type or underlined. These are critical actions to avoid

problems with assembly or when extra care is needed. Parts are Capitalized and Boldface on purpose

for emphasis and identification when reading and easy reference. Cast white metal parts in some cases

are delicate due to replicating in scale. Extra care and caution is required when cleaning, filing parting

lines and adjusting to dry fit.

Prime, paint and dry fit all cast parts prior to assembling. Keep primer and paint to a minimum to retain

fine details. When dry fitting parts if excess paint is an issue scrap off paint as needed for a good fit.

Keep in mind it is better to have two or three light coats rather than one thick coat of paint. Fill casting

voids with putty if required and then sand and prime before painting.

Take your time, learn and enjoy the build process as much as the finished model.

Building Strategy: Due to the number of laser cut parts in the kit for the wings; it is recommended to

clean, file, dry fit then paint the wood once the wings are assembled.