Pump unit to deliver fresh hot domestic water (DHW) ModvFresh 2 T

Rev.0 - 18/02/2021

Page 4 of 7

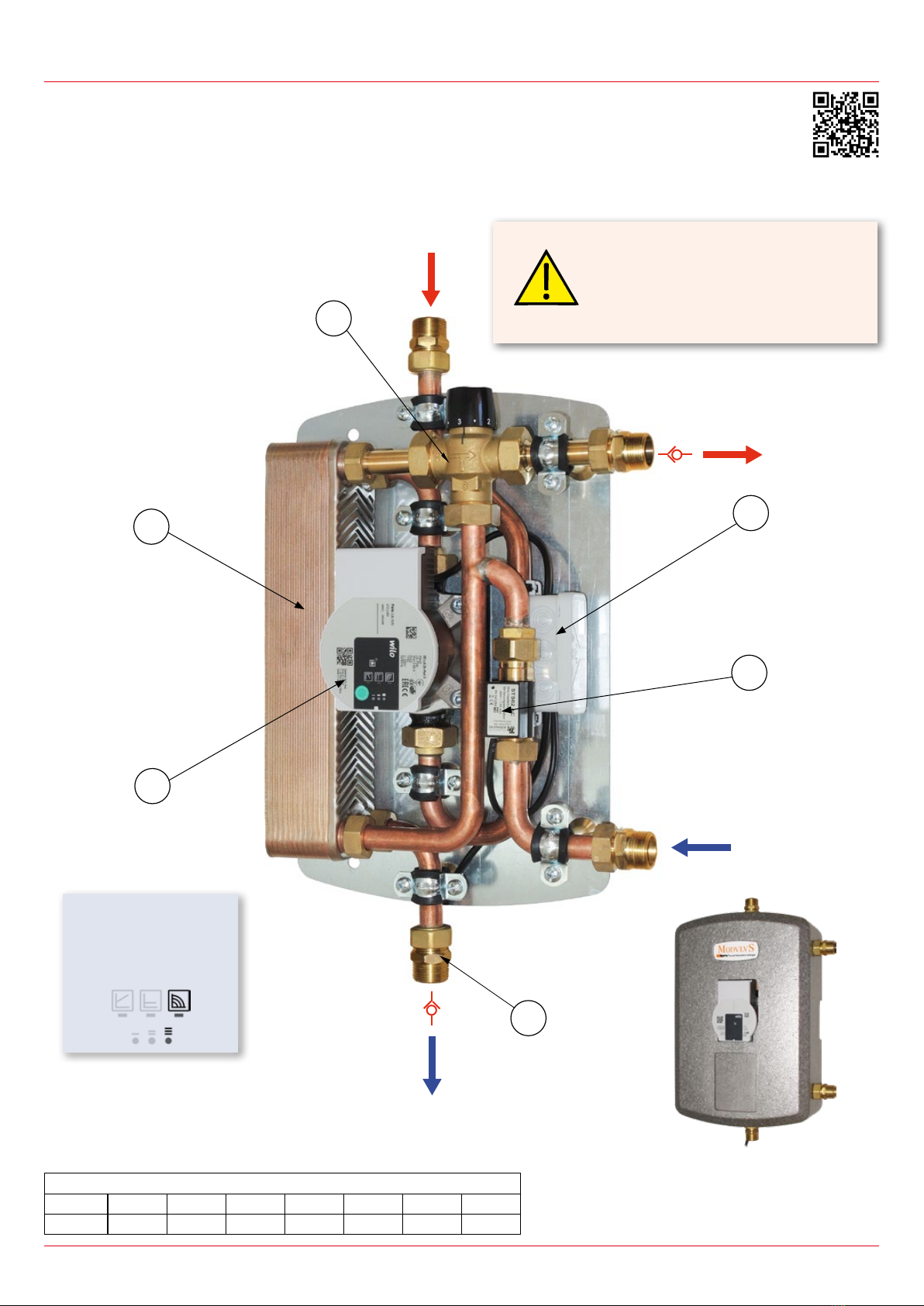

PERICOLO DI USTIONI

Per impedire ustioni all’utenza, non

superare mai i 60°C di temperatura

dell’acqua erogata.

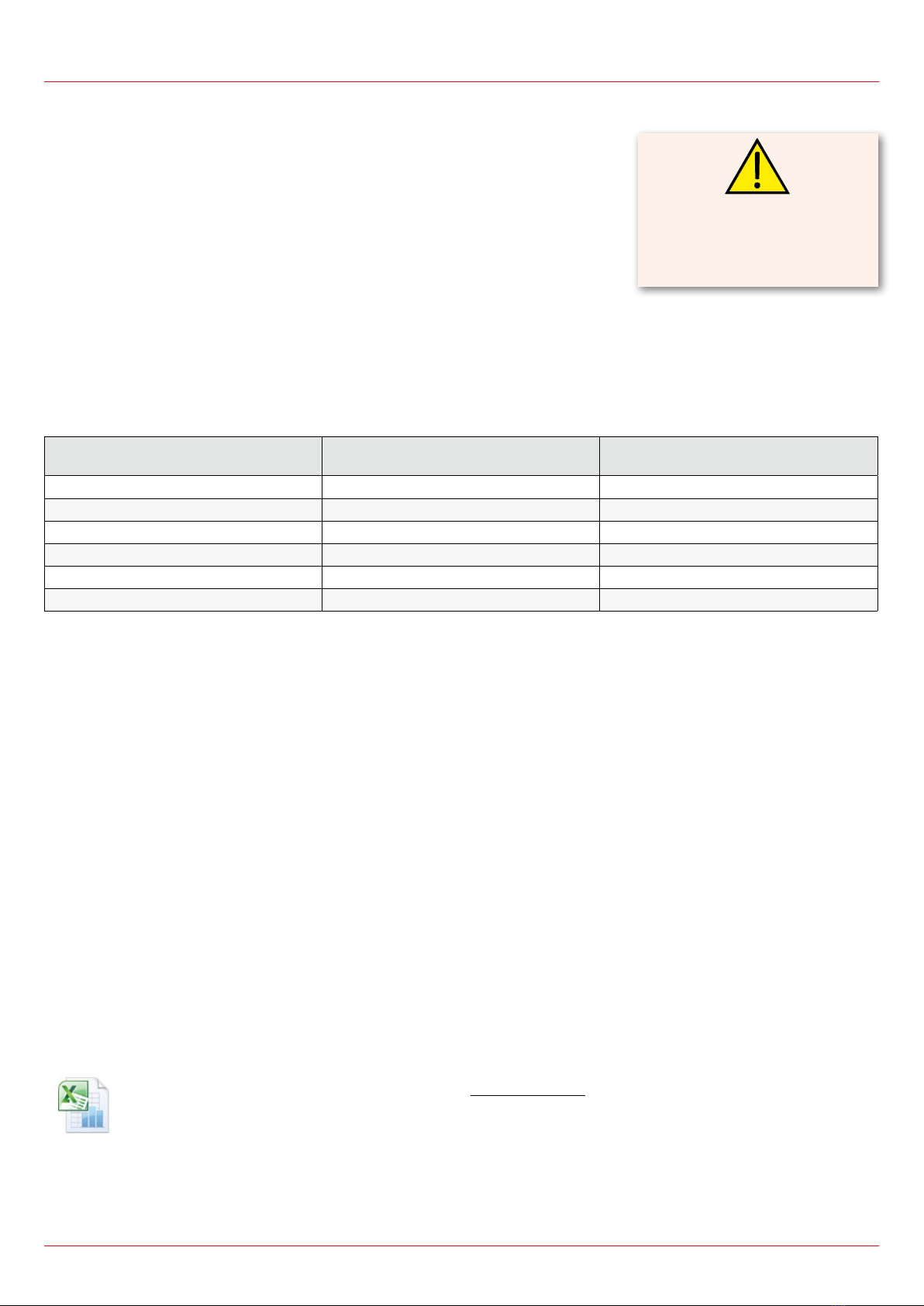

Minimum delivery capacity

To ensure a constant temperature of the DHW delivered, a minimum ow of delivery capacity is required. In the following table there is

an example of delivery with a cold water temperature of 10°C on the supply: minimum deliveries are shown necessary to ensure stability

at 45°C requested by the user, making various assumptions of water temperatures provided by the tank.

Water temperature on supply

from the tank

Minimum capacity for the model

ModvFresh 2 T 50 kW

Minimum capacity for the model

ModvFresh 2 T 70 kW

55 °C 2 l/min 2,5 l/min

60 °C 2,5 l/min 3 l/min

65 °C 3 l/min 3 l/min

70 °C 3 l/min 3,5 l/min

75 °C 3,5 l/min 3,5 l/min

80 °C 4 l/min 4 l/min

Calculation of performances

It is also possible to download an excel le from the site www.modvlvs.com dedicated to the calculation of the peformances

of the ModvFresh 2 T unit from where you cen get: output power, time of delivery, the overall delivery capacity and recovery

time of the temperature in the tank.

Suggestions / Remarks on the delivery capacity

The temperature into the storage tank must be almost 10K higher than the desired

temperature of the domestic water. Higher dierences of temperature allow to extend the

delivery time of the hot water. In presence of calcareous water we recommend not to

exceed the temperature of 70°C (supply from the storage tank) to avoid limescale into the

secondary side of the plate exchanger, in case put a thermostatic valve (Pict.1).

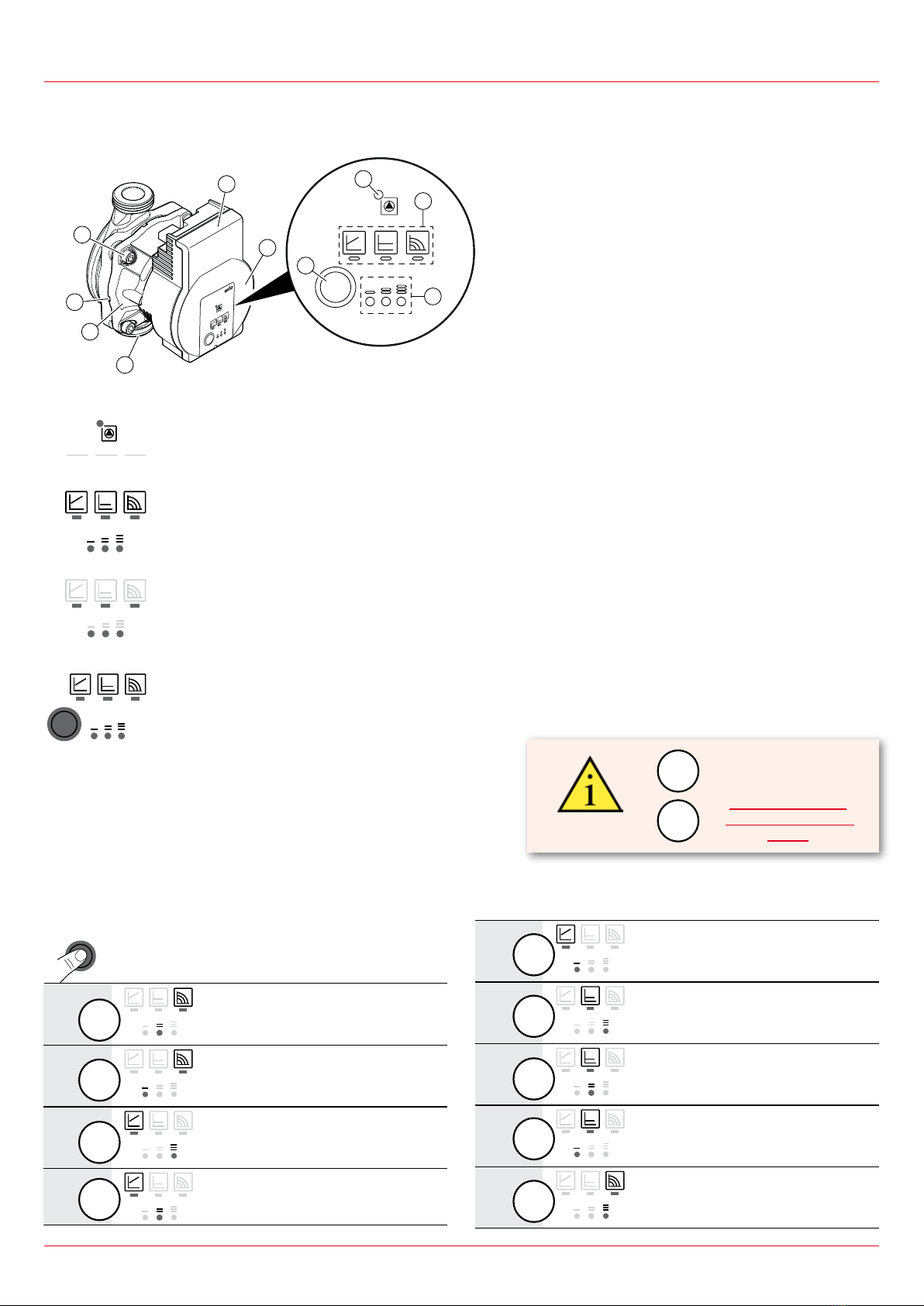

Diagrams of the pump unit performances

The following diagrams relate the user’s ow rate and the supply temperature to the buer storage tank, according to the requested

temperature of DHW. This allows to identify the minimum supply temperature needed to supply DHW at a required temperature and

ow. Vice versa it is also possible to x which is the maximum usable ow at the selected DHW temperature, at the available supply

temperature. Performances are also due to the inlet temperature of the cold water from the water supply system; diagrams show three

possibilities with inlet water at 5°C, 10°C and 15°C.

How to read the diagrams

Example 1, shown in the next page (ModvFresh 2 T 50 kW, inlet at 10°C). In this case a DHW ow of 12 l/min at a temperature of 45°C

is required. Crossing the desired DHW temperature curve, it follows that the supply from the buer storage tank must be almost 51,7°C.

Example 2, shown in page 6 (ModvFresh 2 T 70 kW, inlet at 10°C). This is the case in which the supply from the buer storage tank cannot

go over 56°C and we want to see what can be the maximum suppliable temperature at the DHW of 45°C. Crossing the desired DHW

temperature curve, it follows that the ow cannot be over 19,3 l/min.