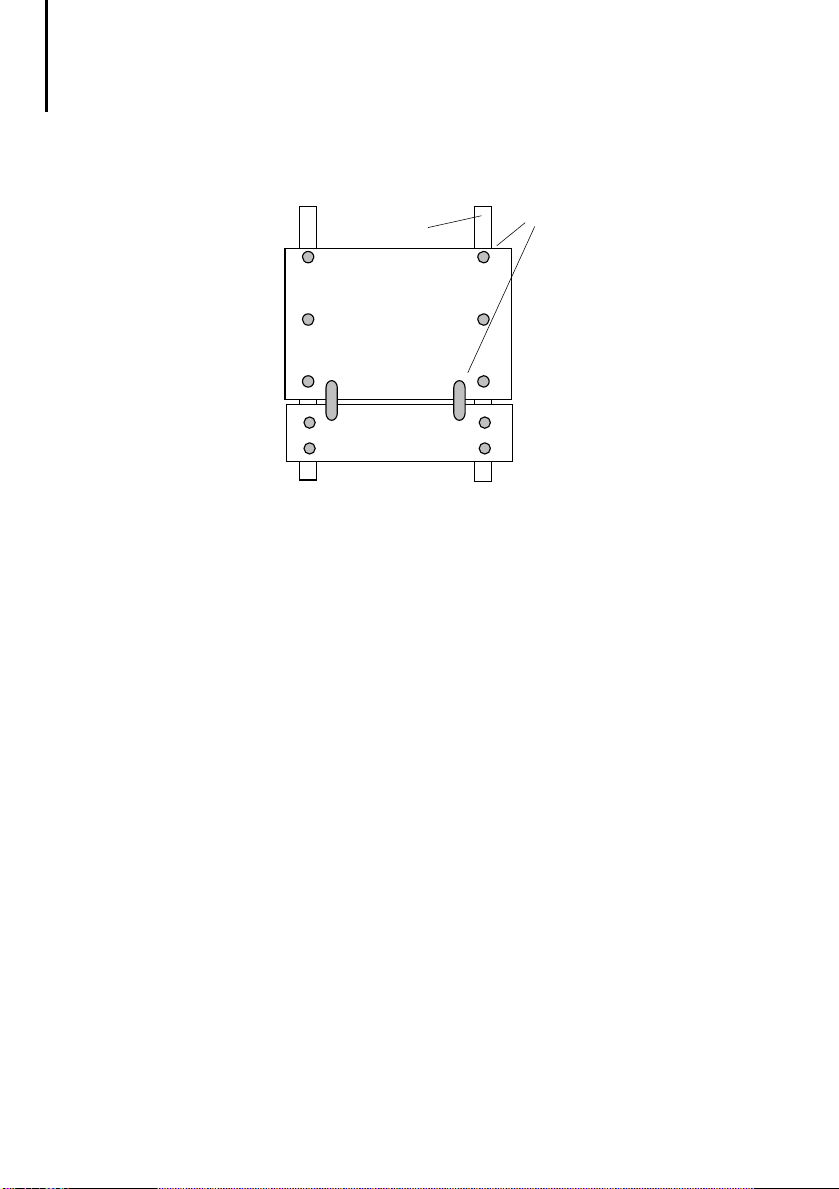

Mounting plates,

CI distribution boards

7

04/97 AWB 27-1287-GB

cable clip must sit snugly around the entire

circumference of the cable screen.

햶Connect the external protective circuit (potential

to earth) to the control cabinet reference potential

(internal protective conductor bar) with a large-

area and low-impedance connection.

Mounting plates,

CI distribution boards

You should use mounting plates as your base.

Connect the mounting plates to the control cabinet

with a low-impedance connection.

Use mounting plates made of galvanized sheet steel

(no enamelling).

The CI distribution board must be fitted with a

galvanized mounting plate. The mounting plate of the

CI distribution board forms the reference potential

surface.

Make sure that connecting points are protected

against corrosion.

Mounting plates must be connected not only to each

other but also to the internal protective circuit with

low-impedance and large-area connections so as to

form one overall reference potential surface. Here

you should connect the mounting plates, mounting

sub-plates, metal device plates to the cabinet

earthing system as often as possible.

Protect the all chassis earth connections against

corrosion.

Total insulation is cancelled by implementing the

provisions of “Reference potential surface”.