x

HD9625 9-⅝” - 22K Tong

TecHnical Manual

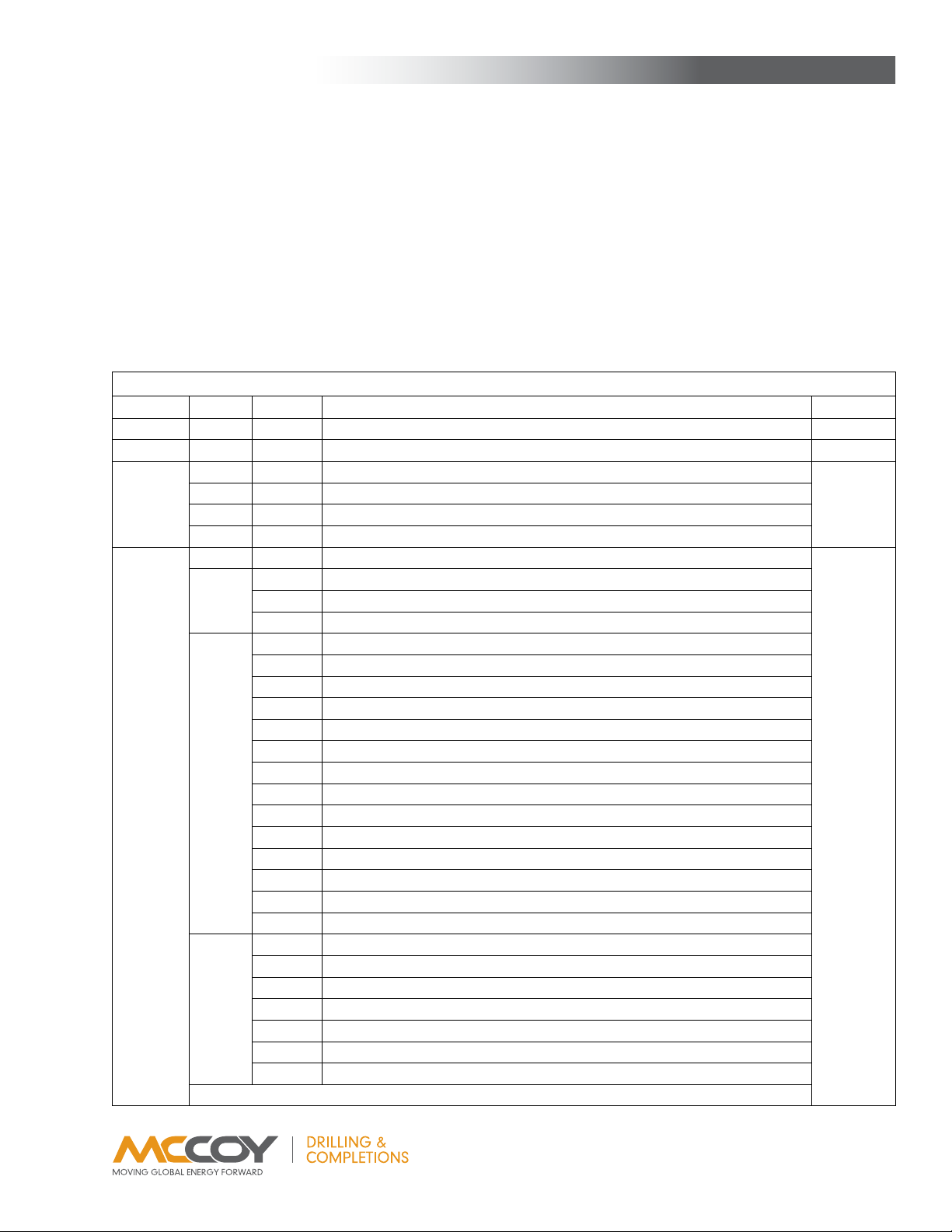

Tables ofconTenTs

SECTION FIVE: PARTS AND ASSEMBLIES

Gear Train ........................................................................................................................................................................ 5.4

Rotary Idler Assembly ...................................................................................................................................................... 5.6

Pinion Idler Assembly....................................................................................................................................................... 5.8

Pinion Assembly............................................................................................................................................................... 5.10

Clutch Assembly............................................................................................................................................................... 5.12

Manual Shifter Assembly.................................................................................................................................................. 5.14

Cage Plate Assembly ....................................................................................................................................................... 5.16

....................................................................................................................................................... 5.18

Hydraulic Supports ........................................................................................................................................................... 5.20

Motor & Motor Mount........................................................................................................................................................ 5.22

..................................................................................................................................................................... 5.24

Door Assembly (First-Generation Safety Door)................................................................................................................ 5.26

Door Assembly (Second-Generation Safety Door) .......................................................................................................... 5.28

Rigid Sling Assembly........................................................................................................................................................ 5.30

SECTION SIX: TORQUE MEASUREMENT

........................................................................................................................ 6.3

............................................................................................................................................. 6.7

6.C.1 Inspection..................................................................................................................................................... 6.8

6.C.2 Fluid Recharge............................................................................................................................................. 6.8

............................................................................ 6.8

6.C.4 Repair And Calibration ................................................................................................................................. 6.9

SECTION SEVEN: OEM DOCUMENTATION

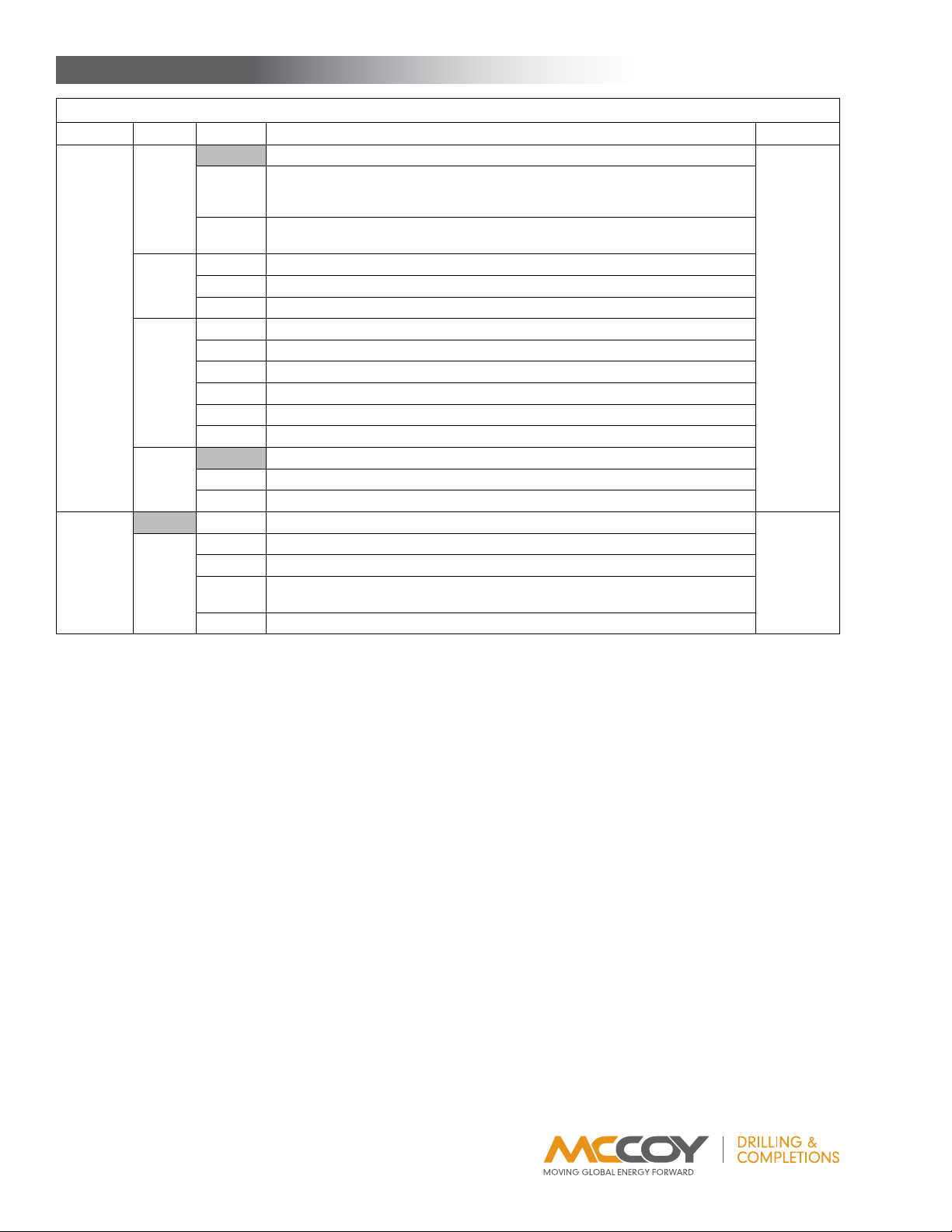

LIST OF ILLUSTRATIONS

IllustratIon 1.a.1: HD9625 Power tong .................................................................................................................................. 1.3

IllustratIon 1.a.2: HD9625 Power tong DImensIons................................................................................................................. 1.4

IllustratIon 2.B.1: major ComPonent IDentIfICatIon 01.............................................................................................................. 2.3

IllustratIon 2.B.2: major ComPonent IDentIfICatIon 02.............................................................................................................. 2.4

IllustratIon 2.B.3: major ComPonent IDentIfICatIon 03.............................................................................................................. 2.5

IllustratIon 2.a.1: slIng angle ................................................................................................................................................. 2.6

IllustratIon 2.D.1: lIft CylInDer & sPrIng Hanger InstallatIon................................................................................................. 2.9

IllustratIon 2.D.2: lIft CylInDer HyDraulIC ConneCtIon ............................................................................................................ 2.10

IllustratIon 2.e.1: HyDraulIC sCHematIC .................................................................................................................................... 2.12

IllustratIon 2.e.2: HyDraulIC ComPonent IDentIfICatIon 01........................................................................................................ 2.13

IllustratIon 2.e.3: HyDraulIC ComPonent IDentIfICatIon 02........................................................................................................ 2.14

IllustratIon 2.e.4: HyDraulIC ComPonent IDentIfICatIon 03........................................................................................................ 2.14

IllustratIon 2.e.5: HyDraulIC ComPonent IDentIfICatIon 04........................................................................................................ 2.15

IllustratIon 2.e.6: HyDraulIC ComPonent IDentIfICatIon 05........................................................................................................ 2.15

IllustratIon 2.e.7: HyDraulIC ComPonent IDentIfICatIon 06........................................................................................................ 2.15

IllustratIon 2.e.8: HyDraulIC ConneCtIons 01 ........................................................................................................................... 2.16

IllustratIon 2.e.9: HyDraulIC ConneCtIons 02 ........................................................................................................................... 2.16

IllustratIon 2.f.1: jaw rePlaCement ......................................................................................................................................... 2.19

IllustratIon 2.H.1: tong susPensIon relatIve toaxIal Centre ................................................................................................. 2.21

IllustratIon 2.H.2: tong susPensIon relatIve tovertICal Centre ............................................................................................ 2.21

IllustratIon 2.g.3: tong levelIng (sIDe-to-sIDe) ...................................................................................................................... 2.22

IllustratIon 2.g.4: tong levelIng (front-to-rear) .................................................................................................................. 2.23

IllustratIon 2.H.1: tong rotatIon Control valve ..................................................................................................................... 2.24

IllustratIon 2.H.2: tong lIft CylInDer Control valve .............................................................................................................. 2.25

IllustratIon 2.H.3: tong lIft CylInDer neeDle valve................................................................................................................. 2.25

IllustratIon 2.H.4: tong motor sPeeD Control valve .............................................................................................................. 2.26

IllustratIon 2.H.5: tong manual sHIft Control ........................................................................................................................ 2.27

IllustratIon 2.I.1: master lIftIng lInk ....................................................................................................................................... 2.29

IllustratIon 2.I.2: settIng BaCkIng PIn to“make-uP” PosItIon.................................................................................................... 2.30

IllustratIon 2.I.3: lIft CylInDer Control - raIse ....................................................................................................................... 2.30

IllustratIon 2.I.4: oPenIng tong Door ...................................................................................................................................... 2.31

IllustratIon 2.I.5: motor Control - make-uP ............................................................................................................................. 2.31

IllustratIon 2.I.6: motor Control - releasIng jaws .................................................................................................................. 2.32

IllustratIon 2.I.7: lIft CylInDer Control - lower...................................................................................................................... 2.32

IllustratIon 2.I.8: settIng BaCkIng PIn to“Break-out” PosItIon................................................................................................ 2.33

IllustratIon 2.I.9: rotatIon Control - Break-out ..................................................................................................................... 2.34

IllustratIon 2.I.10: releasIng tong jaws followIng Break-out & un-tHreaDIng ........................................................................ 2.34

IllustratIon 2.I.11: lowerIng tong usIng lIft CylInDer Control............................................................................................... 2.35

Continued on next page...