Page 3 of 19

MOLT MODELS Parkflyer F6F Hellcat

Thank you for purchasing the MOLT MODELS Parkflyer F6F Hellcat. This kit represents a true

first in parkflyer warbirds in that it possesses characteristics that make it both enjoyable to build

and more importantly, fly. I sincerely hope that you enjoy your new MOLT MODELS kit. Please

visit us at www.moltmodels.com for updates and information on future kits.

GENERAL BUILDING INSTRUCTIONS AND SUGGESTIONS

Please be sure to study the plan sheet and read through the following instructions before

attempting to build your Hellcat. Having a good idea of what to expect as you progress will cut

down on mistakes and allow you to better organize your project. Checkboxes have been provided

in front of each step that allows you to easily keep track of your work. This manual is organized

as blocks of text and illustrations that correspond to the current build section.

The Hellcat is a fully functional aileron, rudder, elevator, and throttle controlled aircraft (4

channel). You may build the Hellcat to fly with aileron, elevator, and throttle only by gluing the

rudder to the vertical stabilizer. If you decide to do this I would recommend that you leave the

landing gear off as take off and landing on a hard surface will be difficult without a rudder. I also

recommend leaving the landing gear off if you intend to fly on grass only. If you fly on a nice hard

surface, the Hellcat with all functions and landing gear is quite impressive. Do not attempt to fly

the Hellcat as a rudder, elevator, and throttle only model.

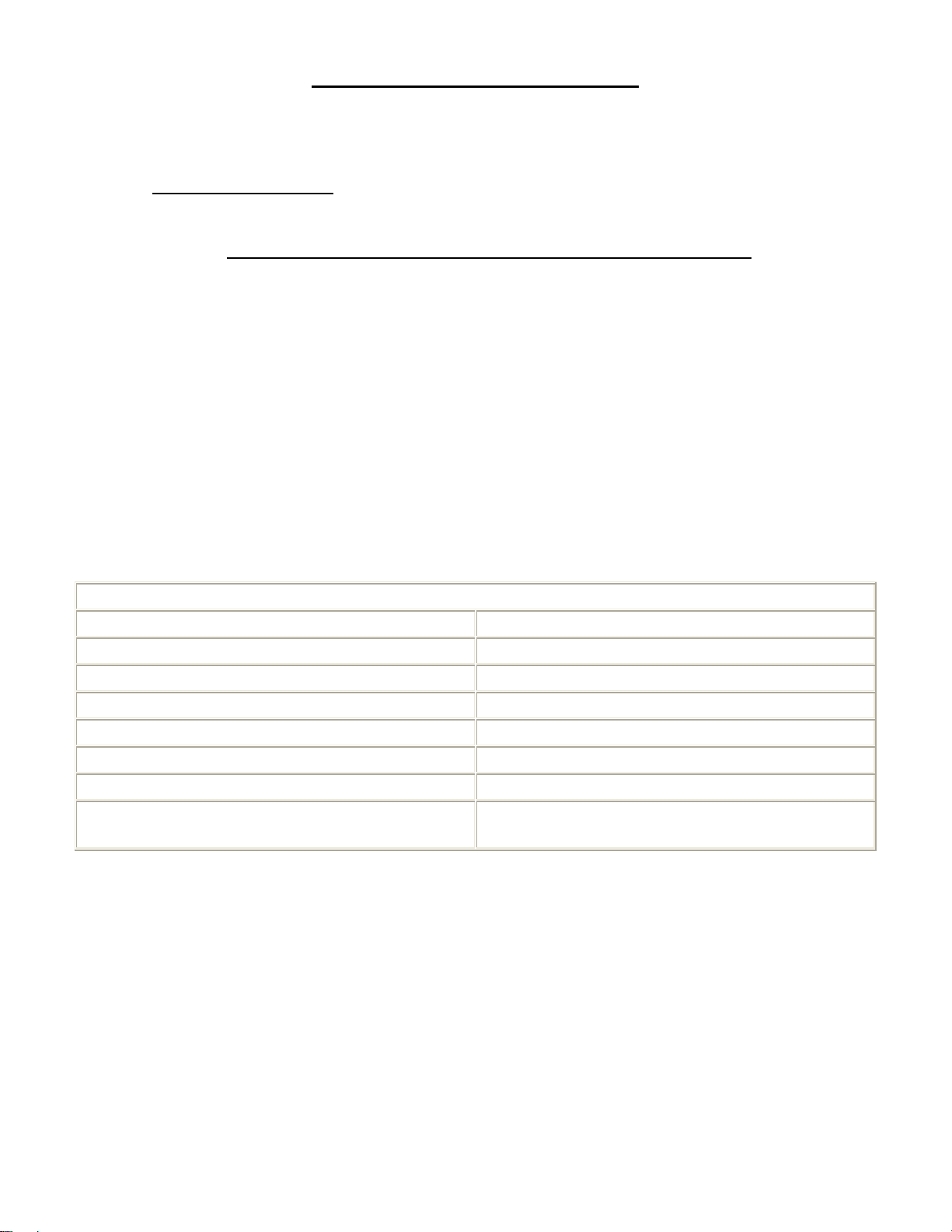

HELLCAT SPECIFICATIONS

Length: 23.5 in

Wing Span: 30 in

Wing Area: 170 in2

Flying Weight: 7.0 ~ 8.0 oz

Wing Loading: 5.93 ~ 6.77 oz/ft2

Power System: GWS DX-A IPS

Functions: Aileron, Elevator, Rudder, & Throttle

Battery Pack: 7 cell 370 mAh NiMH

7.4V ETEC or Kokam Lithium Polymer

What you will need to complete the Hellcat kit:

• Park flyer sized receiver

• Servos (Hitec HS-55 or GWS Pico/Naro) (3 Req. for 4 Channels)

• Speed Control (Castle Creations Pixie 7P or GWS ICS-50 ESC)

• GWS IPS (“A” gearing) and manufacturer recommend propeller

• Dubro Micro E/Z Connectors (5 Req.)

• Dubro Micro E/Z Link (2 Req.)

• 1/2" Dubro Micro Tail Wheel

• 1-1/2” Dubro Micro Lite Wheel (Qty. 2 required)

• 1 roll of Nelson Lite Film AKA Solite covering

• Glue, paint, and other misc. building items