Monogram 15900-012 User manual

Monogram Sanitation

800 W. Artesia Blvd., Compton, CA 90244-9057

TOILET ASSEMBLY

PN 15900-012

COMPONENT MAINTENANCE MANUAL

WITH

ILLUSTRATED PARTS LIST

DISTRIBUTION STATEMENT

This document contains proprietary information of Monogram Sanitation, and it is issued in strict confidence. Except for

rights expressly granted by contract, this document may not, in whole or in part, be duplicated, reproduced, disclosed, or

used for design or manufacturing purposes without written authorization from Monogram Sanitation.

T-1

Jan 10/95

38-31-07

Monogram Sanitation

COMPONENT MAINTENANCE MANUAL

PN 15900-012 Series

38-31-07 Jan 10/95

INTENTIONALLY BLANK

38-31-07

Monogram Sanitation

COMPONENT MAINTENANCE MANUAL

PN 15900-012 Series

Jan 10/95

LIST OF EFFECTIVE PAGES

SUBJECT PAGE DATE

Title T-1 Jan 10/95

Record RR-1 Jan 10/95

of Revisions

Record of RTR-1 Jan 10/95

Temporary

Revisions

Service Bulletin SBL-1 Jan 10/95

List

List of Effective LEP-1 Jan 10/95

Pages LEP-2 Jan 10/95

Table of TC-1 Jan 10/95

Contents

Introduction INTRO-1 Jan 10/95

Description and 1 Jan 10/95

Operation 2 Jan 10/95

3 Jan 10/95

4 Jan 10/95

Testing and 101 Jan 10/95

Trouble Shooting 102 Jan 10/95

103 Jan 10/95

104 Jan 10/95

105 Jan 10/95

106 Blank

Disassembly 301 Jan 10/95

302 Jan 10/95

303 Jan 10/95

304 Jan 10/95

305 Jan 10/95

306 Jan 10/95

SUBJECT PAGE DATE

Cleaning 401 Jan 10/95

402 Jan 10/95

403 Jan 10/95

404 Jan 10/95

Check 501 Jan 10/95

502 Jan 10/95

503 Jan 10/95

504 Jan 10/95

Repair 601 Jan 10/95

602 Jan 10/95

603 Jan 10/95

604 Jan 10/95

Assembly 701 Jan 10/95

702 Jan 10/95

703 Jan 10/95

704 Jan 10/95

705 Jan 10/95

706 Jan 10/95

707 Jan 10/95

708 Jan 10/95

709 Jan 10/95

710 Jan 10/95

711 Jan 10/95

712 Jan 10/95

Fits and 801 Jan 10/95

Clearances 802 Blank

Special Tools, 901 Jan 10/95

Fixtures and 902 Jan 10/95

Equipment

Page LEP-1

38-31-07

Monogram Sanitation

COMPONENT MAINTENANCE MANUAL

PN 15900-012 Series

Jan 10/95

LIST OF EFFECTIVE PAGES

SUBJECT PAGE DATE

Illustrated Parts 1001 Jan 10/95

List 1002 Jan 10/95

1003 Jan 10/95

1004 Jan 10/95

1005 Jan 10/95

1006 Jan 10/95

1007 Jan 10/95

1008 Jan 10/95

1009 Jan 10/95

1010 Jan 10/95

1011 Jan 10/95

1012 Jan 10/95

1013 Jan 10/95

1014 Jan 10/95

1015 Jan 10/95

1016 Jan 10/95

1017 Jan 10/95

1018 Jan 10/95

1019 Jan 10/95

1020 Jan 10/95

1021 Jan 10/95

1022 Jan 10/95

1023 Jan 10/95

1024 Jan 10/95

1025 Jan 10/95

1026 Jan 10/95

1027 Jan 10/95

1028 Jan 10/95

1029 Jan 10/95

1030 Jan 10/95

1031 Jan 10/95

1032 Jan 10/95

Page LEP-2

Monogram Sanitation

COMPONENT MAINTENANCE MANUAL

PN 15900-012 Series

38-31-07 Jan 10/95

INTENTIONALLY BLANK

38-31-07

Monogram Sanitation

COMPONENT MAINTENANCE MANUAL

PN 15900-012 Series

Jan 10/95

TABLE OF CONTENTS

SUBJECT PAGE

Introduction INTRO-1

Description and Operation 1

Testing and FaultIsolation 101

Automatic Test Requirements NA

Disassembly 301

Cleaning 401

Check 501

Repair 601

Assembly 701

Fits and Clearances 801

Special Tools, Fixtures, and Equipment 901

Illustrated Parts List 1001

Page TC-1

Monogram Sanitation

COMPONENT MAINTENANCE MANUAL

PN 15900-012 Series

38-31-07 Jan 10/95

INTENTIONALLY BLANK

38-31-07

Monogram Sanitation

COMPONENT MAINTENANCE MANUAL

PN 15900-012 Series

Jan 10/95

INTRODUCTION

1. General

This publication contains shop maintenance instructions to maintain, troubleshoot and test the

toilet assembly. The toilet assembly is manufactured by Monogram Sanitation.

2. Product Support Services

Contact Monogram Sanitation for repair services, technical documents, replacement parts, and

other product support services.

Monogram Sanitation

800 W. Artesian Blvd.

Compton, CA 90224-9057, USA

Telephone: (310) 638-8445

Fax: (310) 638-8458

SITA: LAXMOXD

3. Layout of Manual

The information in this manual is divided into sections in accordance with Air Transportation

Association, Specification 100, to enable maintenance personnel to disassemble, clean, check,

repair, assemble, troubleshoot, and test the component. An illustrated parts list is provided to

locate, identify, and requisition parts.

4. Revision Service

To ensure that coverage contained in this handbook reflects changes in maintenance concepts and

procedures, revised information is provided to the customer through a letter of transmittal,

advising pages to be removed and replaced by a revision. This letter includes a “highlights” page

which identifies the general reason for change and indicates the effectivity of the change. Any

service bulletins which may be involved are also noted accordingly.

Page INTRO-1

Monogram Sanitation

COMPONENT MAINTENANCE MANUAL

PN 15900-012 Series

38-31-07 Jan 10/95

5. Abbreviations

Abbreviations used throughout this manual are defined as follows:

ASSY Assembly

CMM Component Maintenance Manual

DPL Detail Parts List

EFF Effectivity

FIG. Figure

gpm gallons per minute

IPL Illustrated Parts List

lpm liters per minute

min minute

M.S. Monogram Sanitation

NA Not Applicable

NHA Next Higher Assembly

No. Number

PN Part Number

psig pounds per square inch, gage

REPLD BY Replaced by

REPLS Replaces

RF Reference

SB Service Bulletin

SUPSD BY Superseded By

SUPSDS Supersedes

V Vendor

Page INTRO-2

Monogram Sanitation

COMPONENT MAINTENANCE MANUAL

PN 15900-012 Series

38-31-07 Jan 10/95

6. Special Terms and Handling Used in this Manual

A. Interchangeability between two different parts at one location is defined as follows:

(1) Superseded parts are not interchangeable with the superseding part(s). The notation

(SUPSD BY ITEM XXX) means that the part is not authorized for continued use. The

superseding part is identified with the notation (SUPSDS ITEM XXX).

(2) When a part is replaced by another part the notation (REPLD BY ITEM XXX) is used.

The replacing part is newer and is more desirable than the replaced part. However,

either part can be used. The replacing part is identified by the notation

(REPLS ITEM XXX).

B. All weights and measurements in the manual are in English units with metric equivalents in

parenthesis, unless otherwise stated.

Page INTRO-3/4

Monogram Sanitation

COMPONENT MAINTENANCE MANUAL

PN 15900-012 Series

38-31-07 Jan 10/95

INTENTIONALLY BLANK

Monogram Sanitation

COMPONENT MAINTENANCE MANUAL

PN 15900-012 Series

38-31-07 Jan 10/95

DESCRIPTIONAND OPERATION

1. General

A. The flushing toilet assembly covered in this manual is a separable assembly of the toilet

installation and is capable of receiving, temporarily storing, and during ground servicing,

disposing of waste. Refer to Table 1, Leading Particulars for general specifications of the

toilet assembly.

2. Description

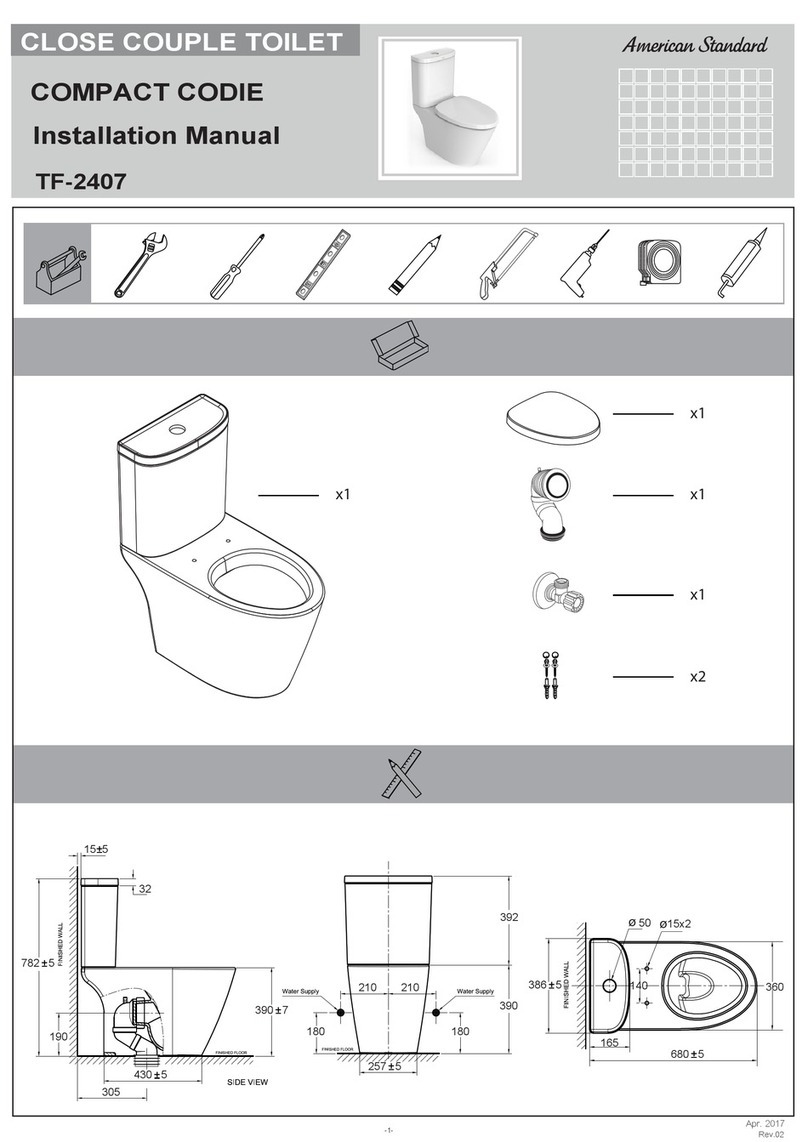

A. The toilet assembly (Figure 1) basically consists of the toilet bowl, (1), timer (2), tank and

top assembly (3), motor-pump-filter unit (4), drain valve assembly (5), solenoid valve

assembly (6), liquid level transmitter (7).

B. The toilet bowl assembly, made of polished stainless steel, is mounted on top of the tank and

top assembly. The timer assembly, a solid-state electronic device used to control sequence

and timing of flushing operation, is also located on the top of the tank. The tank and top

assembly, a Kevlar tank with molded-in structure reinforcement and top is the reservoir for

flushing fluid and waste. The motor-pump-filter assembly (MPFA) consist of a DC Motor

Assembly, static TEF coated perforated filter, pump impeller and rotating spray nozzle

housing. The MPFA is mounted on the tank with filter submerged in the flushing fluid. The

spring loaded, cable actuated drain valve assembly seals the toilet to prevent leakage of

stored fluid and waste and to permit draining and cleaning of the toilet during ground

servicing. The solenoid valve assembly controls the admission of cleansing and charging

fluid. The liquid level transmitter is a solid state electronic device capable of sensing two

discrete points of fill on the toilet tank and transmitting an electronic signal for pre-charge

level or full-tank level. The level sensors are located on an inside wall of the tank and the

transmitter is mounted on the top of the tank.

Page 1

38-31-07

Monogram Sanitation

COMPONENT MAINTENANCE MANUAL

PN 15900-012 Series

Jan 10/95

3. Operation

A. The operation of the toilet begins with the initiation of the flush cycle. The electric motor of

the motor-pump-filter unit assembly is energized for approximately 10 seconds. Throughout

the flush cycle, flushing fluid is drawn thought the filter by the pump and discharged into the

toilet bowl in a swirling action to wash waste into the tank assembly.

B. Toilet Assemblies must be serviced after each scheduled flight by emptying, flushing, and

recharging the tanks with fluid containing a dye-deodorant-disinfectant-chemical-water

solution. Draining, cleaning and filling of the toilet assemblies is controlled from the aircraft

toilet ground servicing panel. During toilet tank draining and cleaning, the tank drain valve

is opened. The drain valve is a plunger type valve which is spring loaded to the closed

position. A pull force of approximately 35 pounds (15.91 Kg) is required to open the valve.

During tank cleaning and filling, fresh water is pumped into the toilet tank from an aircraft

lavatory servicing vehicle. The water enters the toilet tank through an inlet fitting of the

solenoid valve assembly, before going into the rotating spray nozzle via hose connection to

the pump inlet. The rotating spray nozzle is part of the motor-pump-filter assembly. The

pressurized fluid is jettisoned through spray nozzle openings and cleanses the inside of the

filter basket and tank side walls at same time pre-charge fluid is added. After the cleaning

operation the Liquid Level Transmitter will indicate when the fluid reaches the proper pre-

charge level.

4. Leading Particulars

Page 3/4

Leading Particulars

Table 1

Use Toilet Facilities

Electrical Power Rating +28 VDC, 5 AMPS Nom.

Fluid Pump Capacity (Nominal) 10.0+ 1 GPM (37.85+3.79 LPM)

Flushing Cycle (Nominal) 10+2 Seconds

Tank Capacity, Total 7.5 Gal (28.39 Liters)

Usable Capacity 3.8 Gal (14.38 Liters)

Priming Precharge 1.6 Gal (6.06 Liters)

Monogram Sanitation

COMPONENT MAINTENANCE MANUAL

PN 15900-012 Series

38-31-07 Jan 10/95

INTENTIONALLY BLANK

38-31-07

Monogram Sanitation

COMPONENT MAINTENANCE MANUAL

PN 15900-012 Series

Jan 10/95

TESTINGAND FAULT ISOLATION

1. Testing

A. Place complete toilet assembly over sink or drain opening. Arrange with toilet drain valve

opening above sink or drain.

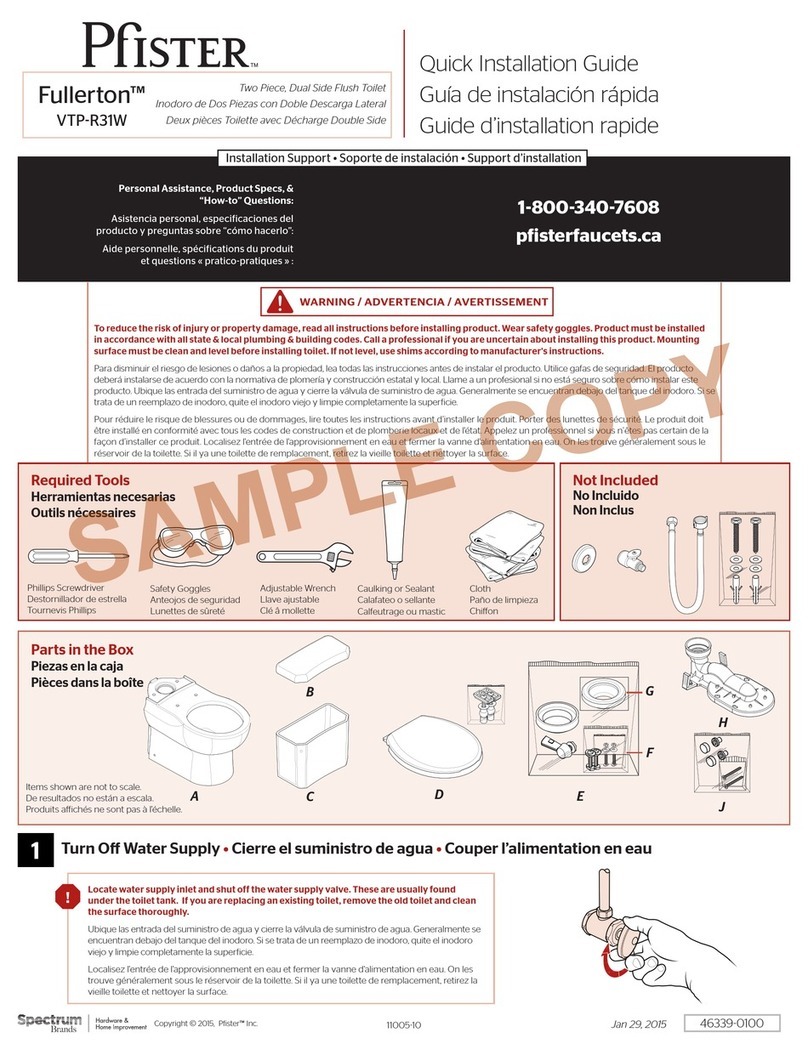

B. Connect 28 VDC Power to the toilet. See the wiring diagram (Figure 101) for connection.

C. Connect a variable pressure water source to the water inlet fitting.

D. Rinse Test

(1) Introduce the water source at 60 psi(g) to the tank. Check and ensure that solenoid valve

is open.

(2) Observe pump spray nozzle for free rotation and adequate rinsing of the toilet tank.

(3) Remove the water source, disconnect the power source.

(4) Check and ensure that the solenoid valve is closed. Check for leaks around the inlet

fitting, antisiphon valve and pump exterior.

E. Motor Pump and Timer Test

(1) Connect the pump and timer to a regulated power supply which conforms to specified

voltage and current requirements.

(2) Depress push-button switch and note toilet function. Cycle duration shall be 10+2

seconds. The swirl pattern should be consistent and vigorous, washing the complete

inner surface of the bowl.

(3) Repeat flush cycle 3 to 4 times.

(4) Measure current surge and running current drain (5 amps nominal).

(5) Inspect for leaks around inlet tube and antisiphon valve.

(6) Drain toilet.

Page 101

Monogram Sanitation

COMPONENT MAINTENANCE MANUAL

PN 15900-012 Series

38-31-07 Jan 10/95

Page 102

F. Bowl Flushing Test

(1) Fill the toilet tank to the specified precharge level (see Leading Particulars).

(2) Upon flushing the toilet it should be observed that the bowl is completely wetted and

water action is vigorous without excessive splashing.

(3) Repeat flushing operation four times to confirm adequate bowl coverage and water

action.

(4) Drain toilet.

G. Liquid Level Sensor Test

(1) Connect the liquid level sensor to the appropriate test harness.

(2) Fill the toilet tank to the precharge level.

(3) Ensure that the precharge indicator light is on.

(4) Continue filling the toilet tank to the full level as indicated in the drawing.

(5) Ensure that the full indicator light is on, and the solenoid valve is shut off.

H. Leak Test

(1) Cap the tank vent. Fill the toilet throughout the bowl aperture until the water level is

approximately one inch below the bowl flushing ring.

(2) Remove any air trapped within the tank.

(3) Allow the toilet to remain in this condition for one hour after which there shall be no

evidence of leakage from any of the toilet components, including the toilet tank, tank

top, gaskets and fitting.

I. Disconnect water supply.

J. Disconnect power supply.

K. Drain all water from tank and remove all water from components.

Table of contents

Other Monogram Toilet manuals

Popular Toilet manuals by other brands

Kohler

Kohler GABRIELLE CLASS FIVE S-EB K-3322T-W installation instructions

YitaHome

YitaHome BFTLPT-2006 Assembly instructions

BEMIS

BEMIS bioBidet HD-5000 owner's manual

Swiss Madison

Swiss Madison Sublime SM-1T205BQ installation instructions

Jacuzzi

Jacuzzi AT1201-DF Instruction

Kohler

Kohler KARING 2.0 K-77780TW-0 Homeowner's guide