6

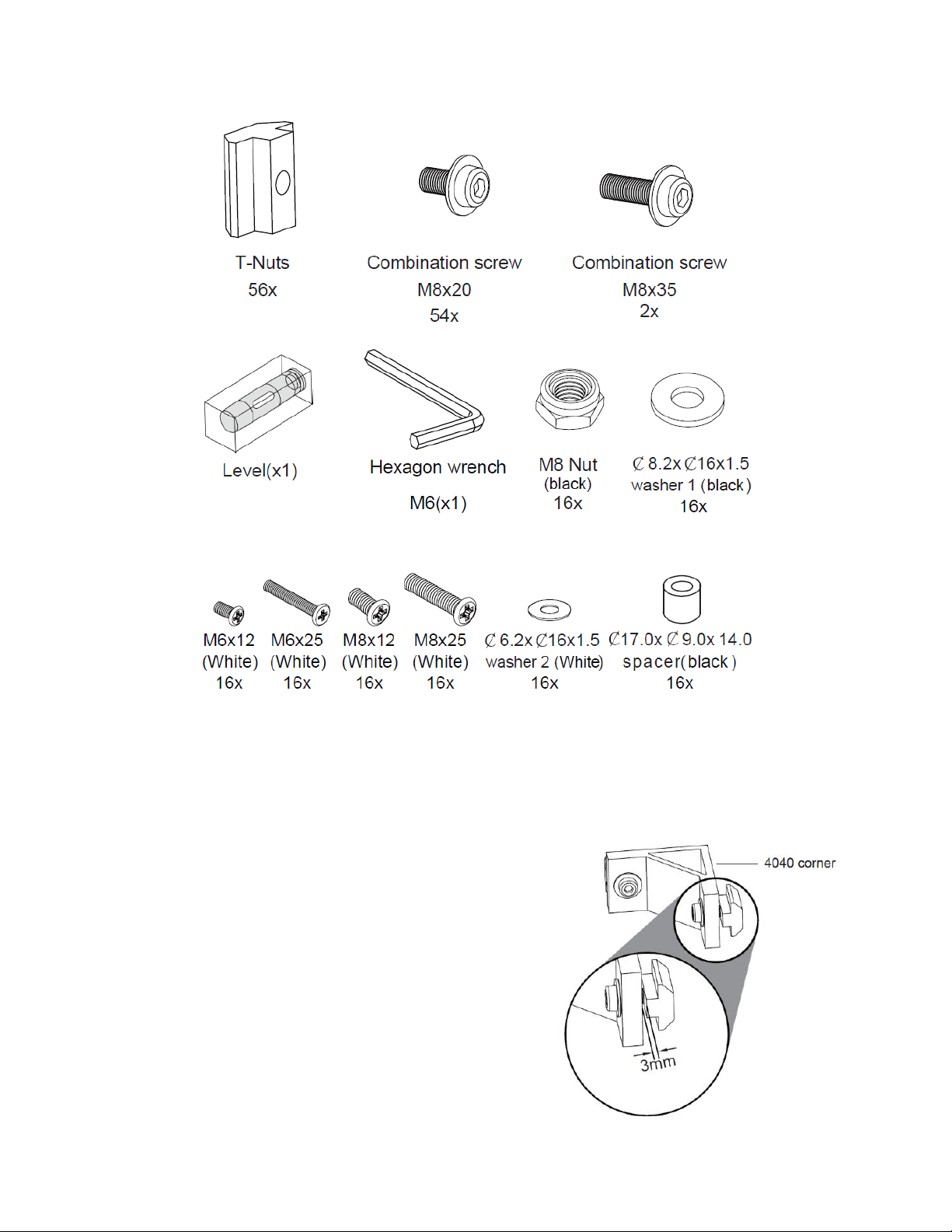

2. For the remaining two 4040 Corner pieces, attach one T-Nut using an M8x20

Combination Screw, then attach a second T-Nut using one M8x35 Combination

Screw. Tighten the M8x35 Combination Screw until the end of the screw is flush

with the back of the T-Nut. This will result in a larger than 3mm gap, but will be

necessary when attaching the lower Beam to the two Base Bars. These two 4040

Corner assemblies will be referred to as Special 4040 Corner Assemblies.

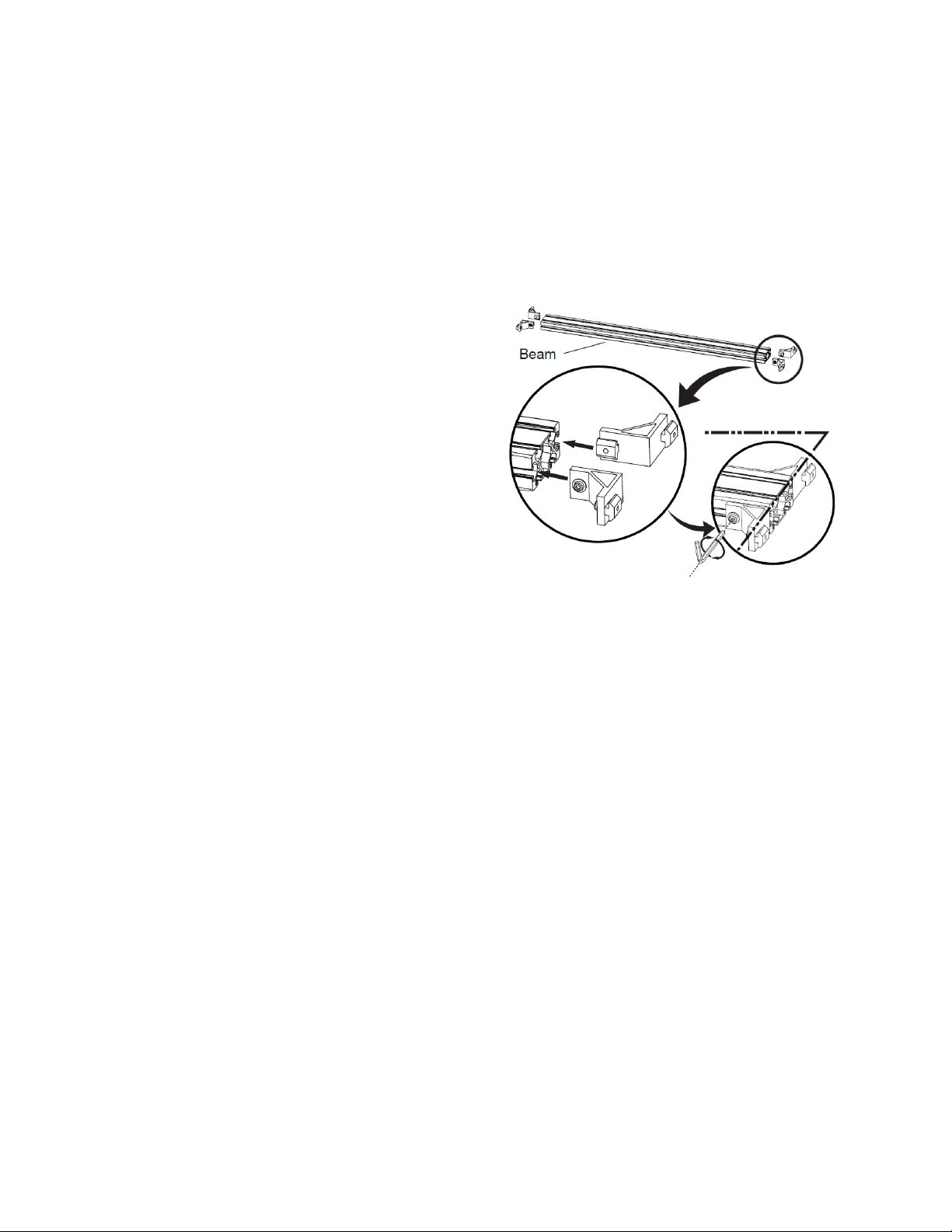

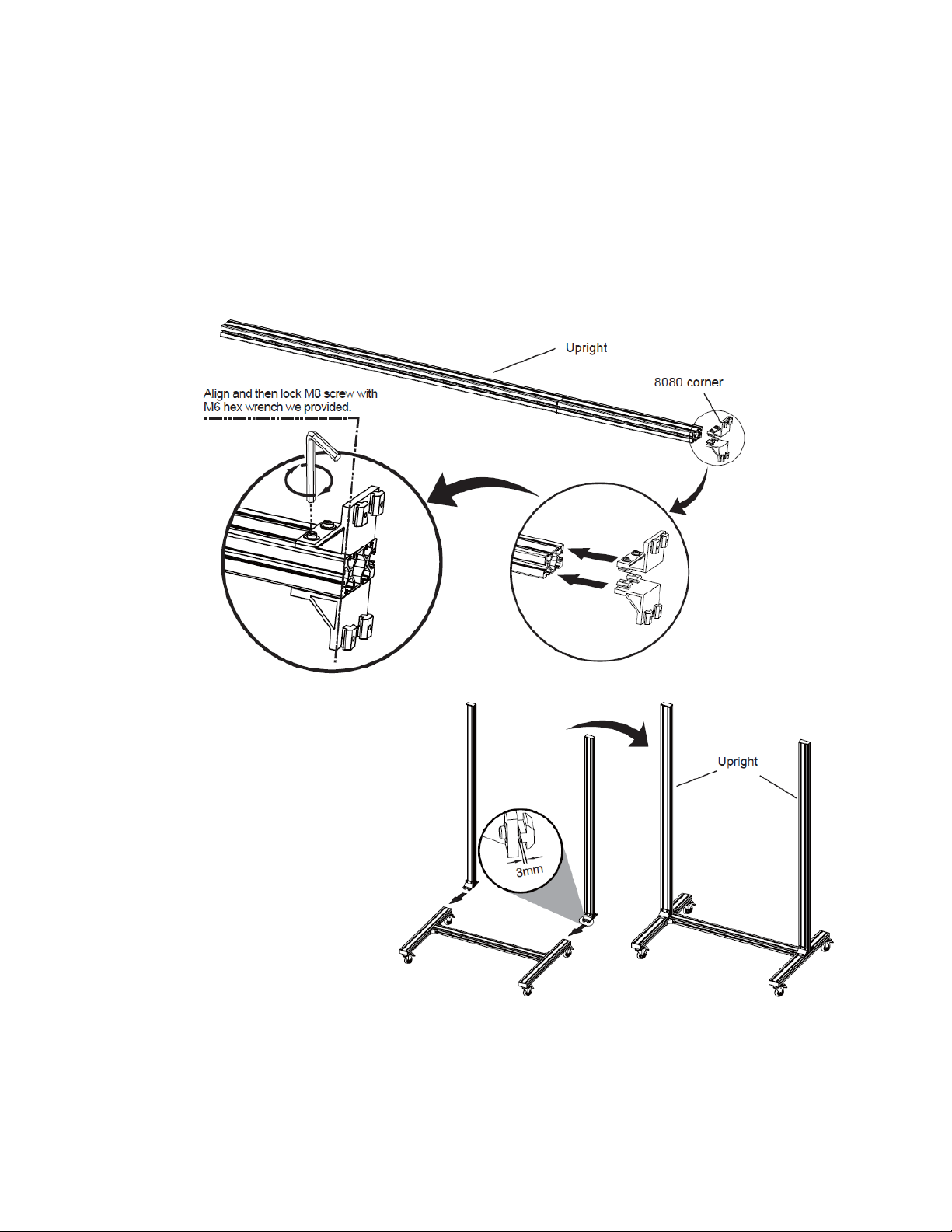

3. Create two Upper Beam Assemblies by

attaching four Ordinary 4040 Corner

Assemblies. To do this, align the T-Nut

with the groove in the Beam and slide

the Corner Assembly into the groove

until the exposed side of the Corner

Assembly is flush with the end of the

Beam. Tighten the M8x20 Combination

Screws on the T-Nuts inserted into the

Beam grooves using the included M6

Hexagonal Wrench.

4. Create one Lower Beam Assembly by attaching two Ordinary 4040 Corner

Assemblies on one side of the Beam, using the instructions in step 3 above. Then

attach the two Special 4040 Corner Assemblies to the other side of the Beam, with

the sides with the M8x35 Combination Screws on the outside. Ensure the exposed

side of each corner assembly is flush with the ends of the Beam, then tighten the

M8x20 Combination Screws on the T-Nuts inserted into the Beam grooves using the

included M6 Hexagonal Wrench.

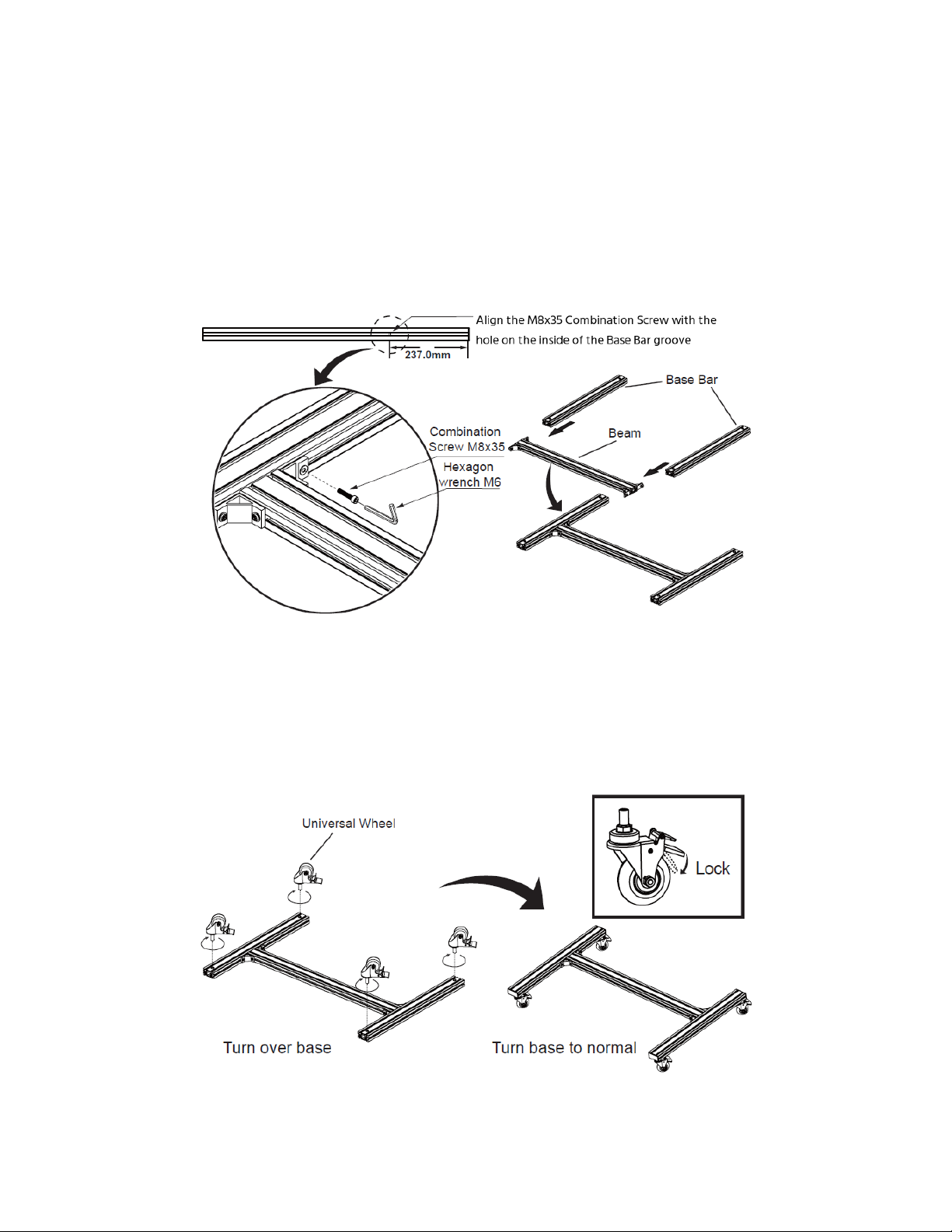

5. Examine each of the two Base Bars. Inside one of the grooves on each, at a distance

of 237mm from the end, is an unthreaded hole. This hole is used to properly position

the Lower Beam Assembly on the Base Bars. Align the T-Nut with the M8x35

Combination Screw into the groove on one of the Base Bars, then slide the Lower

Beam Assembly onto the Base Bar until the M8x35 Combination Screw is aligned

with the hole on the inside of the groove. Ensure that the beam is located on the

short side of the hole in the Base Bar, then tighten the M8x35 Combination Screw

using the M6 Hexagonal Wrench. The screw will extend into the hole, thereby