OPERATOR’S MANUAL

3

DM-4600

Table of Contents

System Overview .......................................................................................................................... 4

Specifications ............................................................................................................................ 5

Installation ........................................................................................................................... 6-7

Quick Start ................................................................................................................................8-13

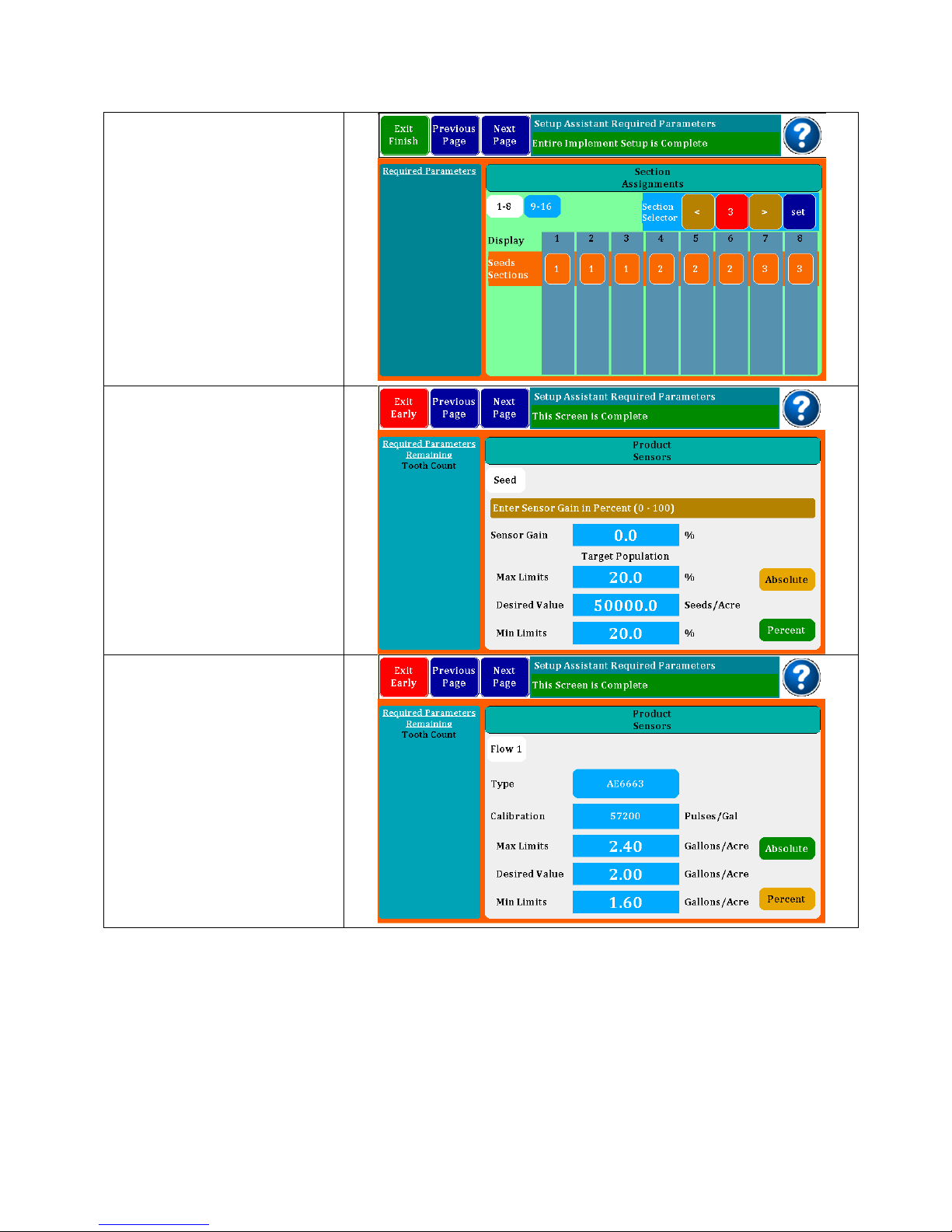

Implement Setup....................................................................................................................... 8

Sensor Setup ........................................................................................................................... 8-9

Target Rates............................................................................................................................. 10

Accessories and Options .................................................................................................. 11-12

Speed Setup ....................................................................................................................... 12-13

Monitor Operations..................................................................................................................... 14

Home Screen...................................................................................................................... 14-15

Dash View ........................................................................................................................... 16-17

Singulation Screen .................................................................................................................. 18

MPH Indicator.......................................................................................................................... 19

Internal GPS Status.................................................................................................................. 20

Lift Switch Configuration / Hopper Type Sensor Setup ...................................................... 21

VAC/Pressure Sensor Setup .............................................................................................. 22-23

Flow meter installation ..........................................................................................................24-27

Master Flow Sensor.................................................................................................................. 28

Post Season Storage............................................................................................................... 29

Harness Pinouts ...................................................................................................................... 30-32

Parts and Accessories...........................................................................................................33-34

Warranty....................................................................................................................................... 36