8

HYDRAULIC PLUMBI G DIAGRAM

for

SI GLE MOTOR SPREADERS

I STALLATIO OTES

1. ydraulic components should be

kept as clean as possible during

assembly operations.

2. Galvanized pipe and pipe fittings

must not be used because flaking of

galvanizing material can cause

damage to major hydraulic

components.

3. A pipe joint sealant compatible with

hydraulic oil must be applied to all

NPT fittings. (Teflon tape is not

recommended.)

4. Sufficient hose should be allowed

for raising dump body without

kinking or stretching hose.

5. ose should be protected where

severe wear may be caused by

vibration or sliding movement.

6. Long runs of hose should be

supported by tie wiring or clamping.

7. Pressure and return hoses,

connected to spinner or auger

motors, may be reversed for proper

motor rotation.

8. Three hose lines to rear of truck

may be installed inside truck frame,

under dump body floor, and secured

in place.

9. Use hose manufacturer's

recommendations for fitting reusable

hose ends.

10. To eliminate hose twisting, allow

hose end clamp to remain loose

until hose end fitting is screwed

tightly in place.

3/4 -1 Wire Hose

3/4 Street Elbow

Pressure Line

From Existing System

3/4 x 1/2

Reducer Bushing

1/2 Street Elbow

Valve 3/4 x 1/2 x 3/4

Elbow

To Tank

1/2-1 Wire Hose

1

JIC (Flared)

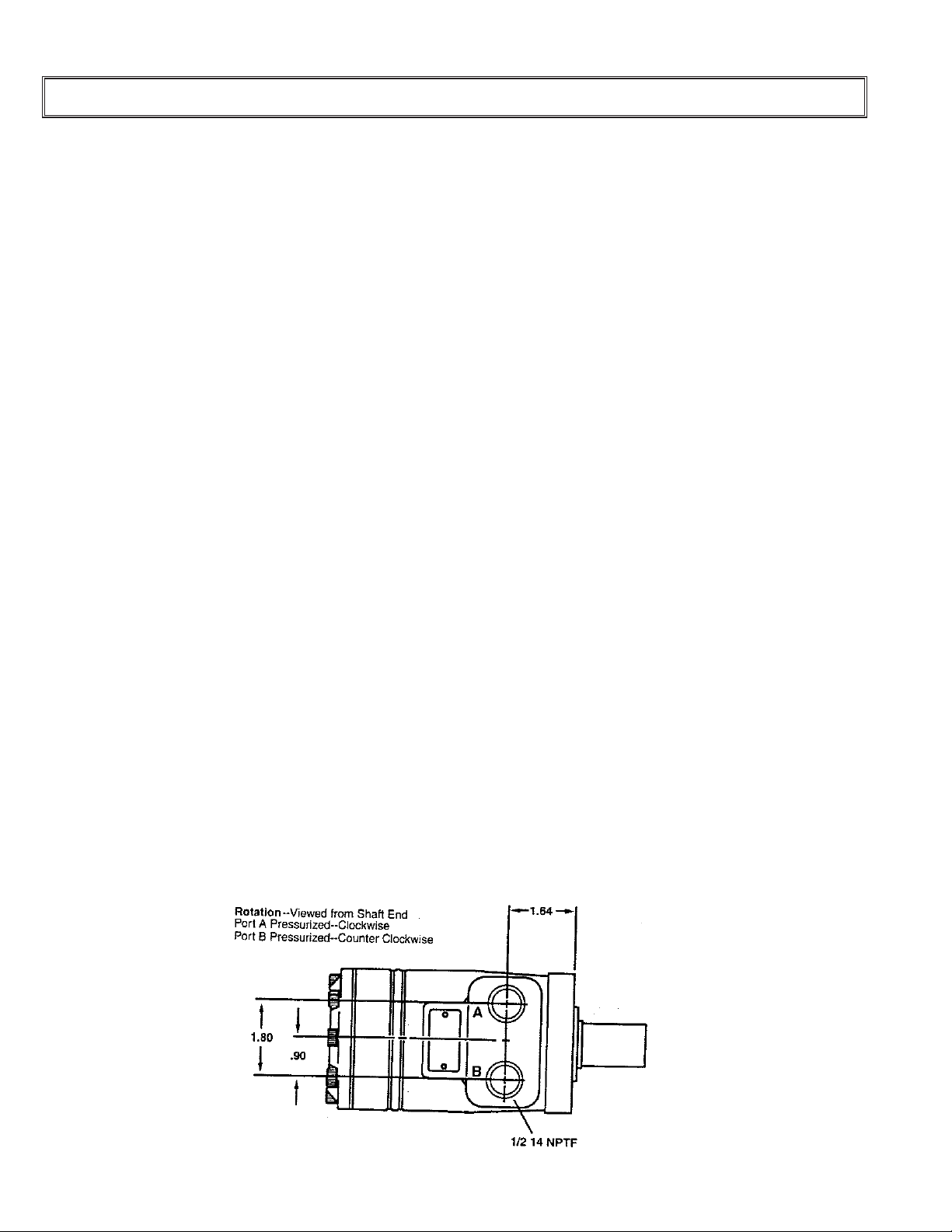

NPT (Pipe Thread) ORB (O-Ring)

Requires pipe

thread sealant Self Sealing