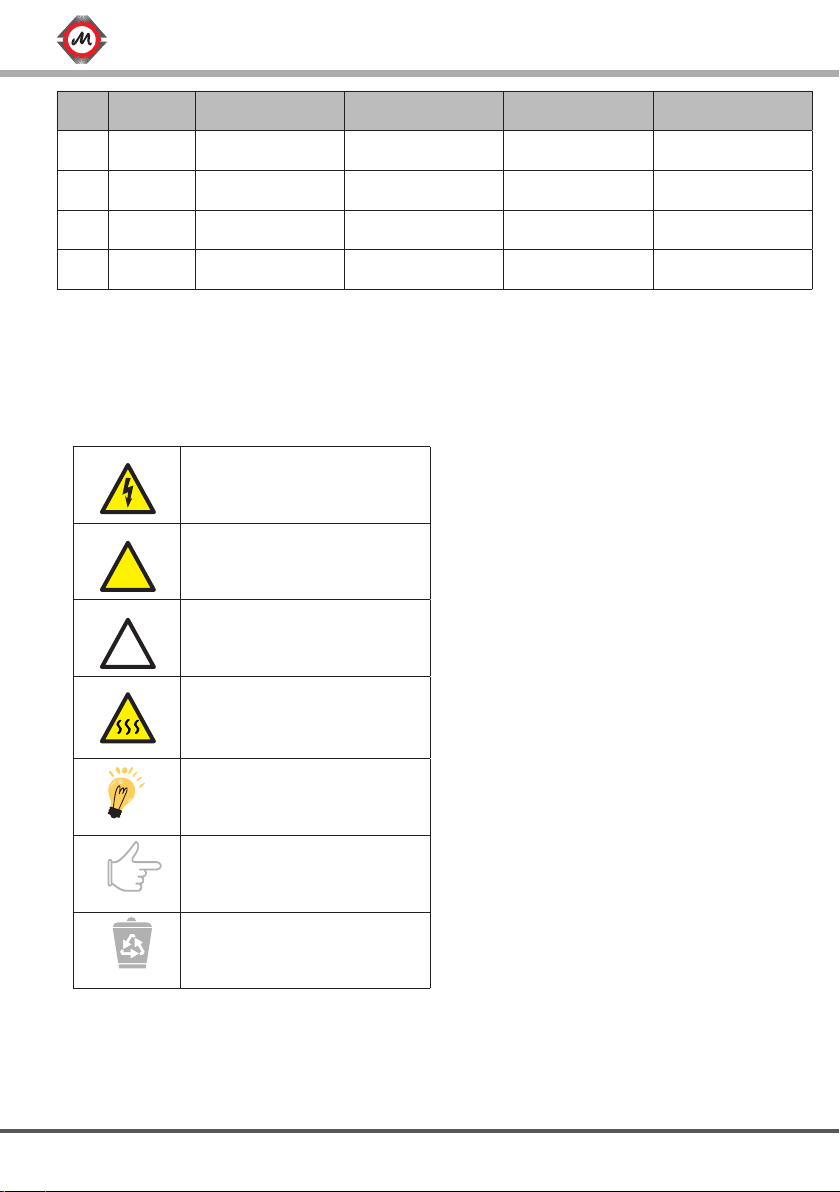

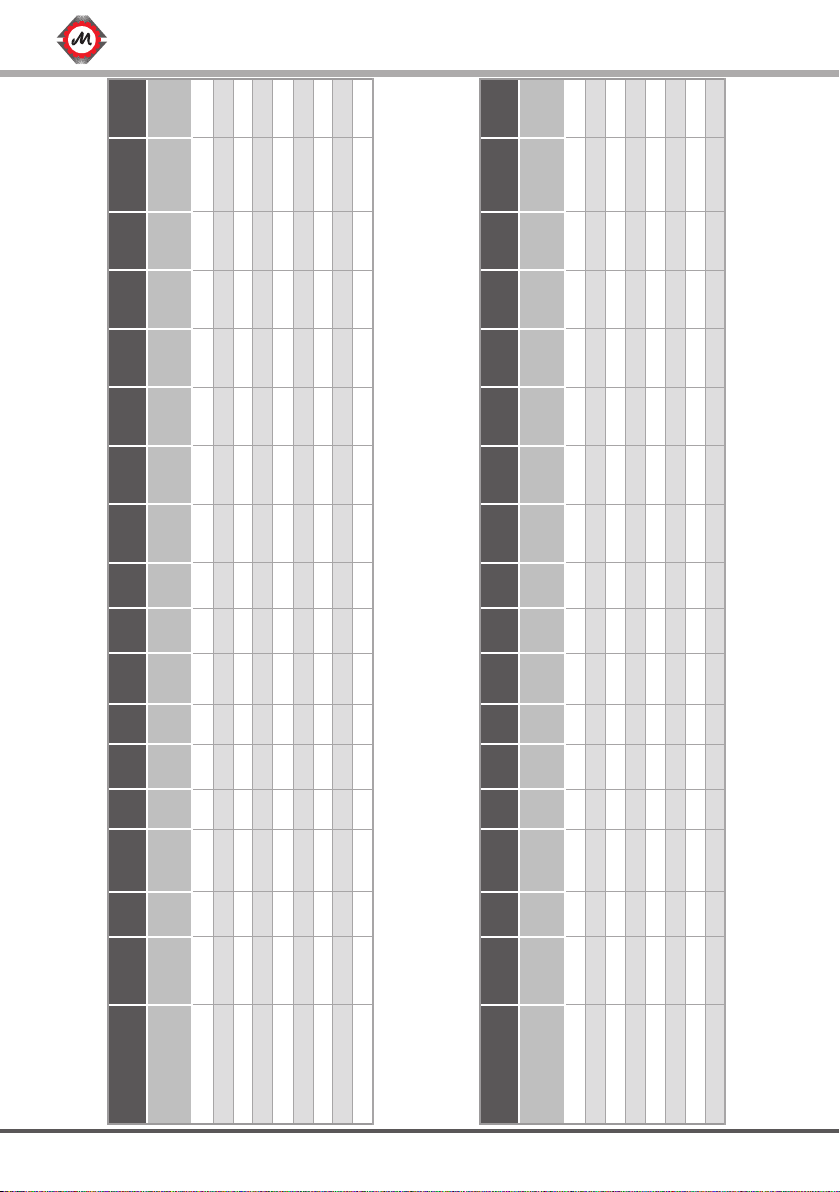

10

MGV20M Type Pn

Speed Vn Cn In Cmax Imax EMF Poles F Rs Ls Static

Load IDuty

Cycle Weight

Code

machine kW [RPM] [V] [Nm] [A] [Nm] [A] [V∙s/

rad] [N°] [Hz] [Ω] [mH] [Kg] [kg∙m2] [Kg]

MGV20152393B401 MGV20M 1,57 75 210 200 13 340 23 8 20 12,5 2,3 10 3000 0,04 180S/H 40% 125

MGV20152913B401 MGV20M 2,4 115 210 200 14,7 340 26 7 20 19,2 1,7 7,4 3000 0,04 180S/H 40% 125

MGV20153823B401 MGV20M 3,35 160 210 200 17,5 340 31 6 20 26,7 1,2 5,3 3000 0,04 180S/H 40% 125

MGV20155103B401 MGV20M 5 239 210 200 23,5 340 40 4 20 39,8 0,73 3,1 3000 0,04 180S/H 40% 125

MGV20151193B401 MGV20M 2,5 119 360 200 8,5 340 15 13 20 19,8 5,3 23 3000 0,04 180S/H 40% 125

MGV20152393B401 MGV20M 5 239 360 200 13 340 23 8 20 39,8 2,3 10 3000 0,04 180S/H 40% 125

MGV20152913B401 MGV20M 6,09 291 360 200 14,7 340 26 7 20 48,5 1,7 7,4 3000 0,04 180S/H 40% 125

MGV20153823B401 MGV20M 8 382 360 200 17,5 340 31 6 20 63,7 1,2 5,3 3000 0,04 180S/H 40% 125

MGV20155103B401 MGV20M 10,7 510 360 200 23,5 340 40 4 20 85 0,73 3,1 3000 0,04 180S/H 40% 125

MGV20L Type Pn

Speed Vn Cn In Cmax Imax EMF Poles F Rs Ls Static

Load IDuty

Cycle Weight

Code

machine kW [RPM] [V] [Nm] [A] [Nm] [A] [V∙s/

rad] [N°] [Hz] [Ω] [mH] [Kg] [kg∙m2] [Kg]

MGV20202553B501 MGV20L 1,9 70 210 265 17 450 31 8 20 11,7 1,7 7,8 3000 0,05 180S/H 40% 145

MGV20203823B501 MGV20L 4,4 160 210 265 23,5 450 42 6 20 26,7 0,9 4,1 3000 0,05 180S/H 40% 145

MGV20205103B501 MGV20L 7,1 255 210 265 31 450 53 5 20 42,5 0,53 2,4 3000 0,05 180S/H 40% 145

MGV20200913B501 MGV20L 2,5 91 360 265 10 450 18 18 20 15,2 5 23 3000 0,05 180S/H 40% 145

MGV20201603B501 MGV20L 4,4 160 360 265 13 450 23 12 20 26,7 3,1 14 3000 0,05 180S/H 40% 145

MGV20202553B501 MGV20L 7,1 255 360 265 17 450 31 8 20 42,5 1,7 7,8 3000 0,05 180S/H 40% 145

MGV20203823B501 MGV20L 10,6 382 360 265 23,5 450 42 6 20 63,7 0,9 4,1 3000 0,05 180S/H 40% 145

MGV20205103B501 MGV20L 14,1 510 360 265 31 450 53 5 20 85 0,53 2,4 3000 0,05 180S/H 40% 145

GEARLESS MACHINE TECHNICAL CHARACTERISTICS: MGV20M - MGV20L

Tab. 2

Tab. 3