Moog Moogerfooger MF-105M MIDI MuRF User manual

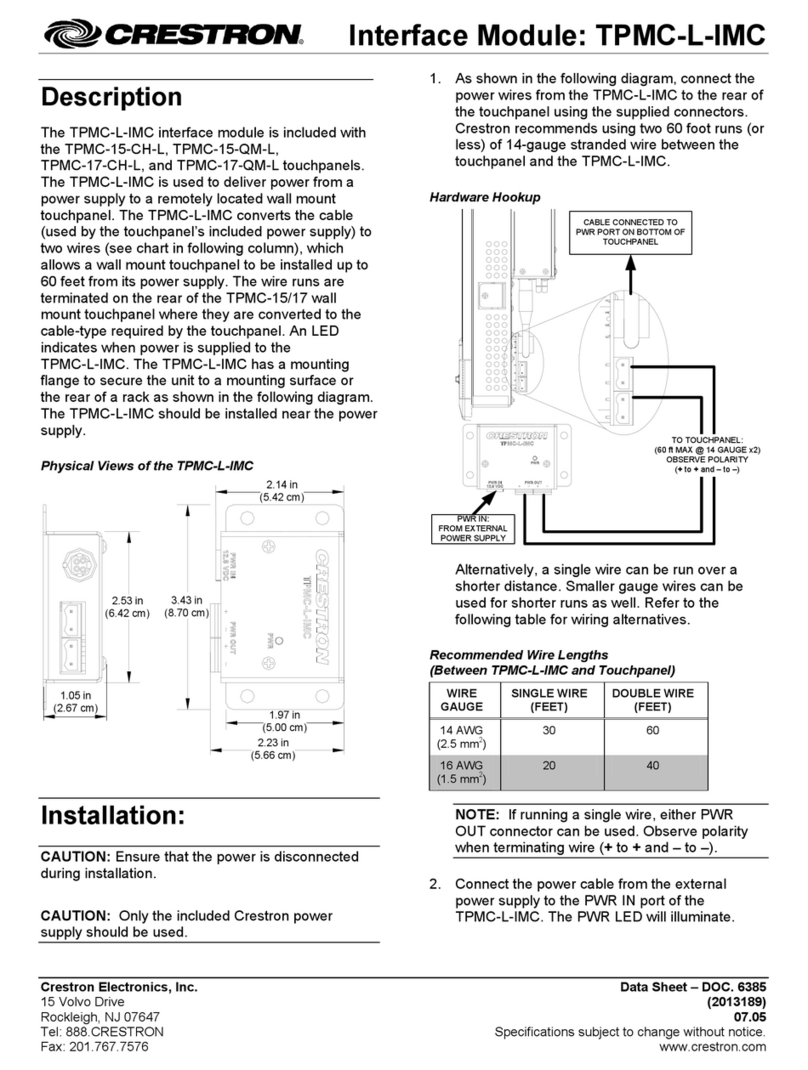

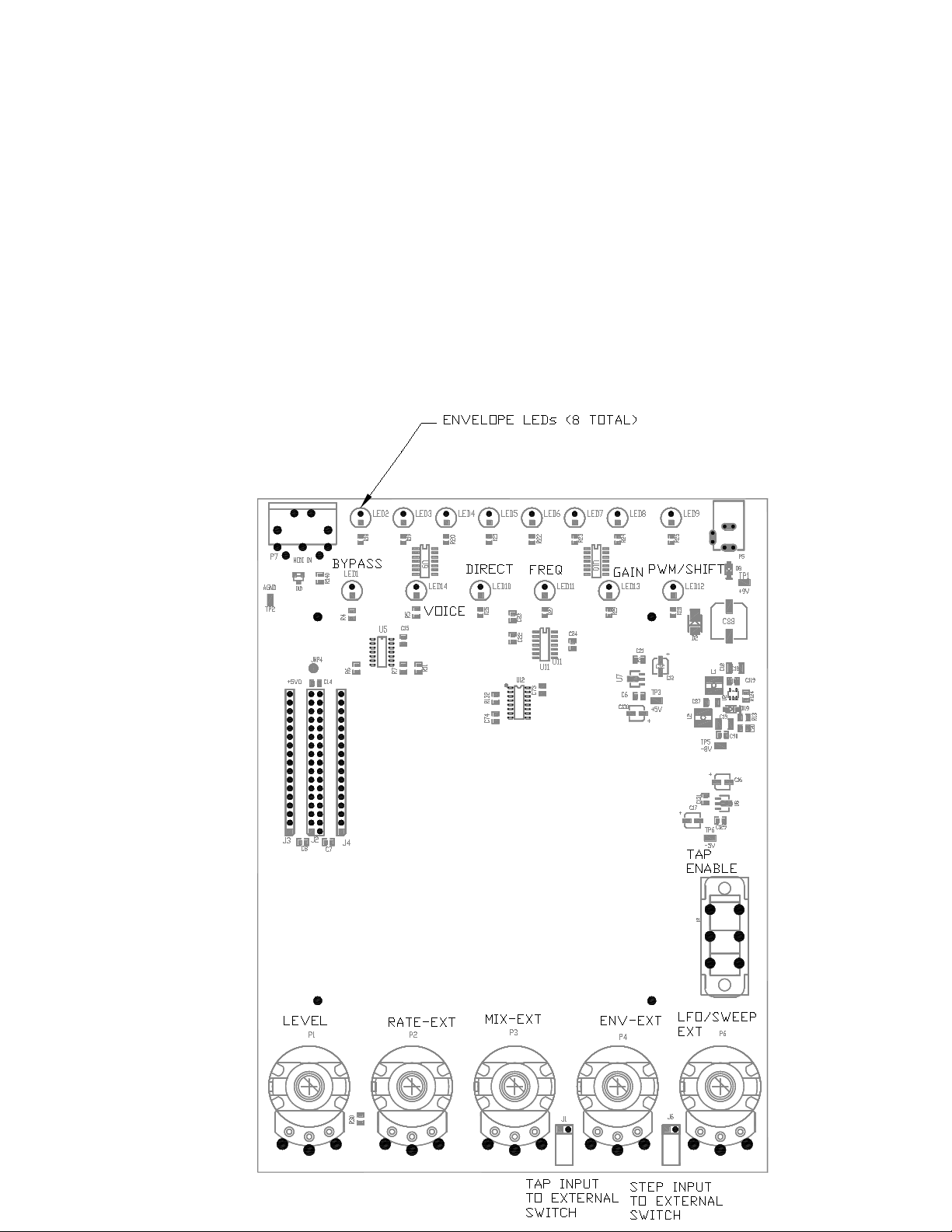

MIDI MuRF Analog Board 11-487

Theory of Operation,

Note: this circuit description refers to the REV A schematic dated 05/19/09.

SHEET 1

EFFECT_IN is the audio signal taken after the bypass switch on page 6. The input network

C5/58-R5-R6-C4 provides DC isolation, radio frequency filtering, and protection of input

amplifier U3A. The output of U3A is the signal AUDIO, which is the amplified audio input

signal.

Negative feedback around U3A goes through U2-A. U2 is a VCA whose gain is controlled by

the current through Q1, which is the sum of the current through R11 and D17/R121. U3B is a

sample-and-hold buffer with level and offset adjustment. The output of this amp determines the

voltage across Rl1.

U14B and associated components are used to buffer, isolate, and attenuate the audio signal from

the audio bus. It is then fed to the MPU to be used as a 0-2.4V DC reference signal for the

compandor circuit. D3 conducts when the peak voltage at U13A is higher than the

COMPANDOR voltage. The COMPANDOR voltage is held by C30 and a capacitor on the

digital board, where it is scanned by the microprocessor. The purpose of the COMPANDOR

voltage is to determine what the highest peak voltage is at the input to the filters. This enables

the microprocessor to determine the status of the overload LED, and perhaps cut down the gain

of the input amplifier to reduce overload distortion.

UI2B is a sample-and-hold buffer with level shifting and gain. Its output is the Direct VCA

CONTROL signal. It controls the overall gain of the direct (non filtered audio) VCA (Sheet 6).

U14A is a sample-and-hold buffer-level shifter / amplifier. Its output is the Filter VCA control

signal. It controls the overall gain of all filter VCAs (Sheets 2 though 5). Note that the Filter

VCA signal is a diode drop across Q16. The current through Q16 is determined by the voltage

at the output of Ul4A and by R50. This is a current mirror configuration. There is a transistor in

each of the filter VCA circuits that matches the properties of Q16.

U10 is a de-multiplexer that routes one of the microprocessor D-A outputs to the inputs of U3B,

U12B, UI4A, and U14B. The signals Mux_A and Mux_B signals select the output routing,

while the signal Mux_EN inhibits U10 when it is high.

SHEET 2

U5B is a comparator and level shifter that takes the signal from the MPU and converts it from

0-3.3V to +/-5V with some hysteresis. This signal is used by the Mux switches to select the

regular or base voicing of the filters.

U5A works in the same way as U5 to convert a duty cycle modulated PWM signal from the

MPU to be used as the shift input to the SHIFT Mux. The duty cycle of this PWM affects the

actual frequency center of the filters. R145/R131/R176 are used to limit the +/-5V swing

slightly to avoid some distortion artifacts in the CD4016.

SHEETS 2 - 5

Sheets 2 through 5 show all eight filters with their respective filter VCAs. With the exception of

the first filter, the circuits are identical topology. Only the two capacitors and two resistors that

set the frequency for each bank change for voice. We will first describe Filters 2 through 8 as

they are all the same and then discuss the difference with filter 1.

Each filter has two modes of primary operation. Those are called Mid Frequency mode and

Base Frequency mode. Normal operation is in Base mode. Mid Frequency Mode is

accomplished by three 4016 switches that switch three parallel resistors around the circuit to

slightly skew the resonant frequency by slightly less than one octave.

First describing base frequency mode: Filter two’s AUDIO signal is applied to the filter

through R55. The filter is a first order band pass filter which consists of U13B, C33, C32, R54

and R66. The output of the filter is at U13B-7.

U23C and U23B switch on and off in response to the SHIFT waveform. When these switches

are on, the filter resonant frequency is raised by about 30%, because R65 and R67 are placed in

parallel with R66 and R54 respectively. When the switches are off, the filter resonant frequency

is not raised. As the duty cycle of the SHIFT signal increases from about 20% to 80%, the

resonant frequency increases about 10%.

To switch from the base voicing to mid frequency voicing the MID_voicing logic signal from

U5B is applied to 2 4016 gates. These gates close two parallel resistors, in this case R146 and

R168 around the filter resistors to change the frequency about an octave.

All filters act as described above with the exception of filter 1. Filter 1, when switched to base

voicing, bypasses the band pass filter and swaps it out with a 2nd order low pass filter. U15C

and U15B swap these out.

Filter 1 uses a DG445 rather than a CD4016 so that it can run from the 9V rails and, hence give

more headroom and less distortion. D116/R136 is used to convert the selector signal to

+5/GND fom +/-5V for U15 and R152/Q51/R150 invert this signal for the base voicing.

The output of the filter is applied through C28 and R41 to the bases of Q10 and Q6. The

transconductance of this transistor pair is proportional to the current through them, which is the

same as the current through Q9.

The network of U11B, R40, and Q5 is a voltage-to-current converter. The input VCA_2 from

the digital board is the envelope voltage for Filter 2. It goes from 0V to +2.4 volts. The voltage

at U11B-7 is such that the current through Q5 in milliamperes is numerically equally to the

voltage at the input to the op amp. Note that U11 has voltage rails of +9 but only -5. This is to

limit the off condition of the output to not swing below -5V and reverse bias Q11.

The current through Q9 is a fraction of the current through Q5. This fraction is determined by

the voltage across R34. If the voltage across R34 is zero, then the current through Q9 is equal to

the voltage across Q5. This is very nearly the case when Q12 is shut off. However, when Q12

conducts, there is a voltage drop across R34, and the current through Q9 is reduced to a fraction

of the current through Q5. This fraction depends only on FILT_VCA_CV, which, in turn,

depends on the voltage at the output of Ul4A (Sheet 1). This is how a single voltage at the

output of Ul4A determines the overall gains of all filter VCAs, regardless of the status of the

envelopes.

The collectors of Q10 and Q6 form a balanced differential pair that is bussed to the

corresponding outputs of the other even filter numbers. This buss then goes to the summing

inputs of the "EVEN” or “RIGHT” output amplifier (Sheet 6). Similarly, the collector outputs

of the off filters (FILT 1, FILT 3, FILT 5, and FILT 7) are bussed and go to the summing inputs

of the "ODD" or “LEFT” amplifier.

SHEET 6

The DIRECT VCA is shown in the upper left corner of the sheet. It is actually two VCAs. One

VCA is for the "RIGHT" side summing amplifier, while the other VCA is for the "LEFT" side

summing amplifier. Thus, the direct signal is fed equally to both audio outputs. The amount that

is fed is determined by the DIRECT_VCA-CV signal (U12B sheet 1), which is derived from the

settings of the MIX and the OUTPUT panel controls on the digital board. Note that the Direct

VCA is fed out of phase to the summing amps from the filter VCAs. This is to compensate for

the phase inversion of the filter amplifiers when adding direct signal back in.

U8A and U8B are the two output amplifiers. They are classic 4 resistor balanced differential

amplifiers with the two input resistors being the impedance of the transistor pairs. Q2 supplies a

smoothed bias voltage of about +7 volts that enables the collectors of the filter VCA's to be

connected directly to the inputs of U8A and U8B.

U6 performs the bypass/on switching functions. The switch signal BYPASS comes from the

digital board. This bypass switch diverts the AUDIO_IN from the jack board either to the Page

1 input filter or directly out as well as switching the output signal from the U8 op amps to the

input signal. The audio feeds to the LEFT/MONO OUT and RIGHT OUT jacks on the jack

board. They are summed to mono on the jack board. Note that when the MFI05 is in bypass,

the bypass output appears only at the LEFT/MONO jack unless JMP11 solder blob is shorted.

SHEET 7

The power inverter and regulators are shown in the upper right corner. D8 provides polarity

protection. It is a low Vf Schottky diode so that the linear regulators do not reach drop out

voltage. D1 conducts if an over voltage situation occurs (power spikes or the wrong input

voltage).

The input +9V is filtered and run to the analog section and the rest of the voltage regulators. U1

produces the +5V analog for the digital and analog PCBs, while U18 produces +5V digital used

on the digital PCB only.

U4 is a 1.4MHz switching regulator of a CuK variety. This provides the -8.25V analog power.

This switcher produces lower ripple output and on the input than a conventional buck/boost.

The switcher should always be operating in the continuous mode of operation (as opposed to

discontinuous operation). If this is not the case then the value of L2 may need to be increased to

provide for continuous operation. L1 provides the switch from Pin 1 of the IC though the cache

diode of D19 and out L2. From there the -9VDC is regulated down to -5VDC via U7 for the

switches and lower noise circuitry of the MuRF.

The negative signal has been reduced from -9V to -8.25V to reduce power loss and to add some

slight asymmetrical clipping to the filter outputs for the characteristic MuRF warm distortion

sound.

The rest of the page consists of two headers. J1 receives all signals from the digital board and

either uses them (mostly on Page 1) or sends them to the jack board via P6.

End of Theory of Operation documentation.

Supply voltage reference:

+5V ±100mV Digital at +5VD TP4 Test point.

+5V ±100mV Analog at +5V TP3 Test Point

-5V ±100mV Analog at -5V TP6 Test Point.

+8.7V +/- 500mV (Raw Power Source = 300mV less than input voltage) on PCB at +9V TP1

Test Point

-8.25V ±200mV Analog on PCB at -8V TP5 Test Point.

MIDI MuRF Digital Board

Test Procedure and Fixture Documentation

NOTE: This document refers to the Test Fixture used in manufacturing. However, most

of the procedures can be followed using a normal, assembled MF-105M MuRF pedal. If

you have any questions about testing the MIDI MuRF, contact

techsupport@moogmusic.com.

MIDI

MIDI may be tested in several ways.

The easiest way is to use the MIDI testing tab of the Moog utility “MIDI_MuRF.exe”

The first tab has some MIDI controls on it.

Other ways include using a simple sequencer that may be downloaded from

http://www.reaper.fm/download.php

Alternatively MiDI OX

http://www.midiox.com/

may be used or a simple MiDI controller keyboard such as an M-Audio Oxygen 8

http://www.m-audio.com/products/en_us/Oxygen8v2.html

MIDI MuRF DIGITAL BOARD CHECKOUT PROCEDURE

Modified July 2009 from the original May 28, 2004

Version

Initial Firmware load and check out

1. Install B.U.T.

•Place the Digital Board Under Test onto test fixture and clamp down.

a) Verify that there is an insolated washer on each screw terminal before

placing B.U.T on PCB.

b) Add hold down nut to each screw stud. Verify insolated washer is glued to

each hold down nut.

c) Clamp fixture clamp onto J1 making sure that it makes only a slight push

on PCB and that clamp does not hit RN4 or any other part.

•Verify test fixture pogo pins line up with pads on J1.

•Verify LEDs can bend forward 9 degrees from the PCB.

•Connect stomp cable to J3 on B.U.T.

•Connect JTAG programmer to J4 (Red pin 1 stripe to middle of PCB)

•Connect MIDI Out device to test fixture MIDI IN jack

•Apply +9.5V +/- 1V power to the fixture.

2. Turn all controls on BOTH the board under test (B.U.T.) AND the test fixture to the

center position. Set the Pattern Selector switch to position 2. Raise all 8 faders to the top

(full on). Set the tap switch to “off”. If the B.U.T. has not yet been loaded with firmware,

the +9.5V current going in to the test fixture should be around 140mA (+/- 20mA).

3. Load the boot loader firmware onto the MPU using the Silabs USB JTAG programmer

(DK# 336-1182-ND) via J4 on the BUT. The Red Pin 1 side goes to the middle of the

PCB.

•On the Connect/Disconnect tab select JTAG interface, apply power to the BUT and

select “Connect”.

•From the Download tab select the current Boot Loader file (

“MM_Booter_v1.0_122.hex” as of this writing) and check “Erase all code space

before download”.

•Press Download and when complete press Go. The unit will flash an initialization

sequence on the three LEDs.

•When done the three LEDs on the BUT should light up green and input current

should increase slightly to around 175mA (+/- 20mA).

•Press Halt, on the download tab.

•Press Disconnect on the Connect Disconnect Tab

•Power down B.U.T. and remove JTAG programmer.

4. Power B.U.T. back up and verify the following voltages and conditions. (note you may

connect ground to the loop below the MIDI connector).

•All three green LEDs are lit up. (Note if this does not happen due to reworked board

power up with two B.U.T. switches to right while pressing bypass switch to boot in

bootloader mode).

•Verify total 9.5V current draw is under 200mA (around 165mA)

•Verify +3.30V +/- 75mV at TP3.

•Verify +3.27V +100mV / - 75mV at TP4. Verify that this voltage is slightly lower

than the TP3 voltage.

•Verify +2.43V +/- 50mV right leg of any pot. (Note this voltage will not come up

before boot loader is installed)

•Verify +5V +/- 100mV at J1-2 (Note: This voltage is generated on test fixture not

BUT)

•Verify -5V +/-100 mV at J1-1 (Note: This voltage is generated on test fixture not

BUT)

5. Run the Moog “MM_Tester_v1.0_122.exe” application to finish programming.

a. If there are not 3 green LEDS on the B.U.T then boot in hidden mode by sliding

LFO and FREQ switches to the right and powering up with the bypass button

pressed. (note this is required for booter 1.0)

b. Select your MIDI output device, set to Channel 1 and click on “Open MIDI”

c. Select the Firmware tab and hit … to brows for the current MIDI firmware.hex file

(MM_Firmware_v0.5_121.hex.as of this writing). Note please check with Moog

Music for the current firmware before each major MIDI MuRF build as the

firmware is always being updated.

d. Click the Download button and watch the status window on the application as well

as the B.U.T. On the B.U.T. you should see BYPASS LED blinking red and green

as data transfers. Then the DRIVE and RATE LEDs will turn red and the BYPASS

LED blinks very fast as data is verified and copied into memory. If successful, unit

will reboot into normal MIDI MuRF operating mode.

e. Note that the pattern LEDS are flashing in unison. Click on Patterns TAB, select

Factory Defaults, Pattern All, Same and click Download. You should see the

Bypass LED blink read and green as data transfers. When done the patterns LEDs

will not flash in an orderly fashion. If the pattern switch is set to pattern #2 then

they will move from right to left, one LED at a time.

f. Select the Tables tab and click download. You should see the Bypass LED blink

read and green as data transfers.

UI and I/O Testing.

6. ON/BYPASS FUNCTION (“Stomp Switch”): Press the Bypass STOMP SWITCH on the

tester panel.

a. The middle LED on the B.U.T. should alternate between green and red. (Tests LED

and Switch input to MPU)

b. The BYPASS / ON LED on the fixture panel should light up yellow when the LED

on the B.U.T. is green, but turn off when it is red. (Tests Bypass output from MPU)

7. ENVELOPE OUTPUTS: On the fixture panel, set the RATE EXTERNAL, MIX

EXTERNAL, ENVELOPE EXTERNAL, and LFO/SWEEP EXTERNAL knobs to their

mid positions. Set the TAP ENABLE switch up (OFF position). On the B.U.T., place a knob

on the rotary pattern selector, then set the ENVELOPE and RATE controls to their mid

positions (note ENVELOPE slightly to the left of center works best). Set the LFO (was

BANK) switch to the left (OFF) position. Set the VOICING switch to the Mids position

(right). Set the PATTERN selector to position #2, and raise all the sliders. Be sure the

BYPASS light is green (on).

a. The ENVELOPE LEDs should all light up in sequence, one at a time from right to

left.

b. Set the PATTERN selector to position #1. The ENVELOPE LEDs should now all be

on and not moving. Raise and then and lower each slider in turn.

c. The sliders should move smoothly. Each LED should get dim and then bright as its

corresponding slider is moved down and then up.

If you observe these conditions, then the envelope outputs are working (Jl-5 to Jl-12) and

the sliders are mechanically OK.

8. PATTERN RATE: On the B.U.T., set the PATTERN selector back to #2. On the fixture

panel, turn the ENVELOPE EXTERNAL Pot full CCW.

a. Turn the RATE EXTERNAL pot slowly through its entire range.

b. The speed at which the Envelope LEDs sequence should change from very slow to

very fast. They should step at a rate of about two envelopes per second when the

RATE EXTERNAL pot and the RATE pot are both in mid position. Return the

RATE EXTERNAL pot in mid position.

c. Turn the RATE pot slowly through its range and observer that the speed at which the

Envelope LEDs sequence should change from very slow to very fast.

d. Return the RATE pot to the middle position/

If you observe the conditions, then the RATE pot and the RATE EXTERNAL input are

working.

9. ENVELOPE SHAPE: Set the RATE pot in mid-position. On the fixture panel, turn

the ENVELOPE EXTERNAL pot slowly through its entire range.

a. The individual envelope LEDs should indicate that the envelope shape is

changing. The envelopes should be very short when the ENVELOPE

EXTERNAL pot is at either extreme, or long when the pot is in the middle.

b. Now set the ENVELOPE EXTERNAL pot in mid position. On the B.U.T.,

turn the ENVELOPE pot slowly through its range.

c. The individual envelope LEDs should indicate that the envelope shape is changing.

The envelopes should be very short when the ENVELOPE pot is at either extreme, or

long when the pot is in the middle.

If you observe the conditions, then the ENVELOPE pot and the ENVELOPE

EXTERNAL input are working.

10. AUDIO LEVEL INDICATOR: On the fixture panel, turn the AUDIO LEVEL

pot through its entire range.

a. The left-most DRIVE LED on the B.U.T. should go from not illuminated, to

green, to orange, to red, as you turn the AUDIO LEVEL pot counter-

clockwise. It should be orange in the middle position.

If you observe this condition, then the “compandor” voltage input (Jl- 13) and the OVERLOAD

led are working.

11. AUDIO INPUT GAIN: On the B.U.T., turn the DRIVE pot slowly clockwise.

a. The orange GAIN ( INPUT LEVEL) LED on the fixture panel should go from

brightly lit to completely off. No other orange LEDs should change at this time. This

verifies that the the DRIVE pot, CV_DAC output (Jl-14), and the mux bits

(J1.28,29,31) are all working.

12. MIX POT AND PEDAL INPUT: On the B.U.T., set the MIX pot in mid position and

the OUTPUT pot full clockwise. Then turn The MIX EXTERNAL pot slowly

clockwise through its range.

a. Both the Direct VCA and Filter VCA (Formally D-control and the F-control) LEDS

should go from brightly lit to completely off as you do this. If you observe any rapid

or choppy movement it indicates that the mix tables have not been properly loaded

from the MIDI MuRF Application.

Put the MIX EXTERNAL pot in mid position. On the B.U.T., turn the MIX pot slowly

clockwise through its range.

b. The same thing as above should happen: Both the Direct control and the Filter control

LEDs should go from brightly lit to completely off as you do this.

If you observe this condition, then the MIX pot and the MIX pedal input are both working.

13. OUTPUT LEVEL: Set both the MIX pots to mid position. On the B.U.T., slowly turn the

OUTPUT pot clockwise through its entire range.

a. The Direct VCA control LED should get brighter and the Filter VCA control LED

should get dimmer as you do this.

b. Set the MIX KNOB Full Counter Clock Wise (Dry) and note that moving the Output

knob dims the direct LED but the filter LED remains unchanged (full on)

c. Set the MIX KNOB Full Clock Wise (Wet) and note that moving the Output knob

dims the filter LED but the drive LED remains unchanged (full off)

If you observe this condition, then the OUTPUT pot is working.

14. LFO/SWEEP: On the B.U.T., set the bank switch to LFO On (right position). On the fixture

panel, set the LFO/SWEEP EXTERNAL control to mid position.

a. The LFO/PWM RATE LED should pulsate at a rate of a few times a second.

Now slowly vary turn the LFO/SWEEP EXTERNAL control clockwise through its range.

b. The pulsation of the LFO/PWM LED should vary from very slow to very fast.

Flip the LFO switch back to OFF (left)

c. Adjusting the LFO/SWEEP EXTERNAL should now chance brightness of the

LFO/PWM LED but it should remain on.

If you observe these conditions, then the LFO/SWEEP pedal input and the BANK switch are

working.

15. Voicing:On the B.U.T. Set the Voicing switch to the left (Low) position. Verify that the

Voicing LED on the fixture panel toggles and that the patterns change. The LED should be

on in MIDs position and off in BASS position.

16. PATTERN SELECTOR: The object of this step is to ensure that all twelve positions of

the selector switch are properly connected to the microprocessor through the muxing

diodes. This requires that the test technician watch the envelope LED patterns carefully to

ensure that they correspond to the position of the selector switch.

a. On the fixture panel, set the RATE EXTERNAL knob and the ENVELOPE

EXTERNAL knob to mid position. Be sure that the TAP ENABLE toggle switch is

down (off). On the B.U.T., set the RATE knob to mid position. Set the ENVELOPE

knob to 8 or 9 o'clock, so that the pulsations of the envelope LEDs are short enough

to be distinct but long enough to be easily visible.

b. Now, starting with position #1, turn the PATTERN selector through the twelve

positions. After switching to each position, carefully note the sequencing pattern of

the envelope LEDs.

c. You should see the following patterns. See the MIDI MuRF Manual for

representations of these patterns.

If you observe these patterns, then the PATTERN selector switch is working properly.

17. TAP FUNCTION: Note the right hand (RATE) LED on the B.U.T.

a. The RATE LED should be blinking red.

On the fixture panel, turn the TAP ENABLE switch on (down). Then tap the TAP switch three

times at a rate of about once a second.

b. The RATE LED should now be blinking green, at the rate that you tapped.

Tap the switch 3 times fast and verify that the speed increases to that speed.

Now turn the TAP ENABLE Switch off (up.

c. The RATE LED should now be blinking red at the rate that is set by the RATE

controls.

If you observe all three of these conditions, then the RATE LED, the TAP ENABLE input, and

the TAP input are working correctly.

18. Step Function:With the Tap enable still engaged hit the step momentary switch

a. Note the LEDS sequence only once with each step pushbutton hit

19. MIDI Input. Optional test.

MIDI is verified by loading the application firmware. However if the application is already

loaded it may be necessary to use another MIDI verification test. If so run MIDI_MuRF.exe

and connect a midi channel.

Using the control tabs adjust a slider or button and verify that the B.U.T functions as if that

knob was changed on the B.U.T. For example, if changing the RATE slider the RATE LED

speed changes. The RATE LED will change to Orange to indicate it has received MIDI

data.

Appendix A – MIDI CC Messages

The following MIDI Control Change messages are recognized:

CC1 – Envelope (Note – one of the most expressive ways to “play” the MuRF is to modulate the

Envelope time control manually – a mod wheel would be the perfect type of controller for this –

especially if you are using one of the Note On modes) CC Value 000-003 = Env value 1, CC Value 004-

007 = Env value 2, etc… (128 CC values/32 Env Values)

CC2 – Drive – Values 0-127 = changes of 32 12-bit values/ MIDI CC step

CC3 – LFO Rate/Sweep = Values 0-127. Note When LFO is Off – CC3 functions as “Sweep”; When

LFO is On and “free running” CC3 is the LFO Rate, CC Values 0-127 = LFO Rates .08Hz to 25Hz.

When LFO is On and MIDI MuRF is receiving System Realtime Clock Messages, CC3 functions as a

Clock divider with 16 possible settings for the LFO rate (see Clock divider chart below).

CC7 – Output Level (Standard MIDI Volume command) Values 0-127

CC8 – Mix Values 0-127

CC9 – Pattern Clock Rate. Note that w/no MIDI Clock messages being received, this is a continuous

control the same range as the front panel control. When synced to MIDI, this CC becomes a Clock divider

– with 16 possible settings. (See Clock Divider chart below).

CC85 – LFO On/Off. Values: 0=OFF; 127=ON

CC86 – Freq Bass/Mids. Values 0=OFF; 127=ON

CC87 – Bypass On/Off. Values 0=Off; 127=ON

CC88 – LFO Sync On/Off Values 0=Off; 127= ON (should default to ON). Can enable/disable sync LFO

Rate to MIDI Clock

CC89 – Pattern Clock Sync On/Off. Values 0=OFF; 127= ON (should default to ON). Can enable/disable

sync pattern clock to MIDI Clock

CCs 20-27 – Filters 1-8 EGR_CV DAC Level – receiving any of these CC messages stops the pattern

clock and allows Realtime MIDI tweaking of the DAC levels for each Filter EGR signal. Changing the

Panel Rate control, Rate CV input, or receiving a MIDI Clock start or Clock Continue message restarts

Pattern clock and returns EGRs to Pattern function.

CC102 – MIDI Channel – this is the only Channel Voice Message hat the MuRF responds to an ANY

channel – Values 0-15 = MIDI Channels 1-16.

Quick firmware installation guide for MIDI MuRF:

1.) load "bootloader" firmware (MM_Booter_v1.0_122.hex) via Silabs USB Debug Adapter and Silabs Flash

Programming Utility software for Windows-PC. Flash Programming Utility software can be downloaded (as of 11-

2009) from this link:

https://www.silabs.com/Support%20Documents/Software/UtilDLL.zip

2.) Cycle power to unit; all LEDs should be green. If not, boot to "hidden mode" by sliding LFO and FREQ

switches to the right and powering up with the bypass button pressed.

3.) Connect MIDI output from your computer to the MuRF MIDI IN. Open the software "MIDI_MuRF V0.94

B134.exe" and on the Device menu, select your MIDI output device. Click Open MIDI.

4.) Select the Firmware tab and hit [...] to browse for the current MIDI firmware.hex file

(MIDIMurf_firmware_v1_4_142.hex as of this writing).

5.) Click the Download button and watch the status window on the application as well as the B.U.T. On the B.U.T.

you should see BYPASS LED blinking red and green as data transfers. Then the DRIVE and RATE LEDs will turn

red and the BYPASS LED blinks very fast as data is verified and copied into memory. If successful, unit will reboot

into normal MIDI MuRF operating mode.

6.) Select the Patterns tab in the MIDI MuRF software; defaults should be Pattern: ALL, Download As: SAME.

Click Download.

7.) Select the Tables tab and click Download.

MIDI MuRF should now be running current firmware with all patterns and tables loaded with factory default data.

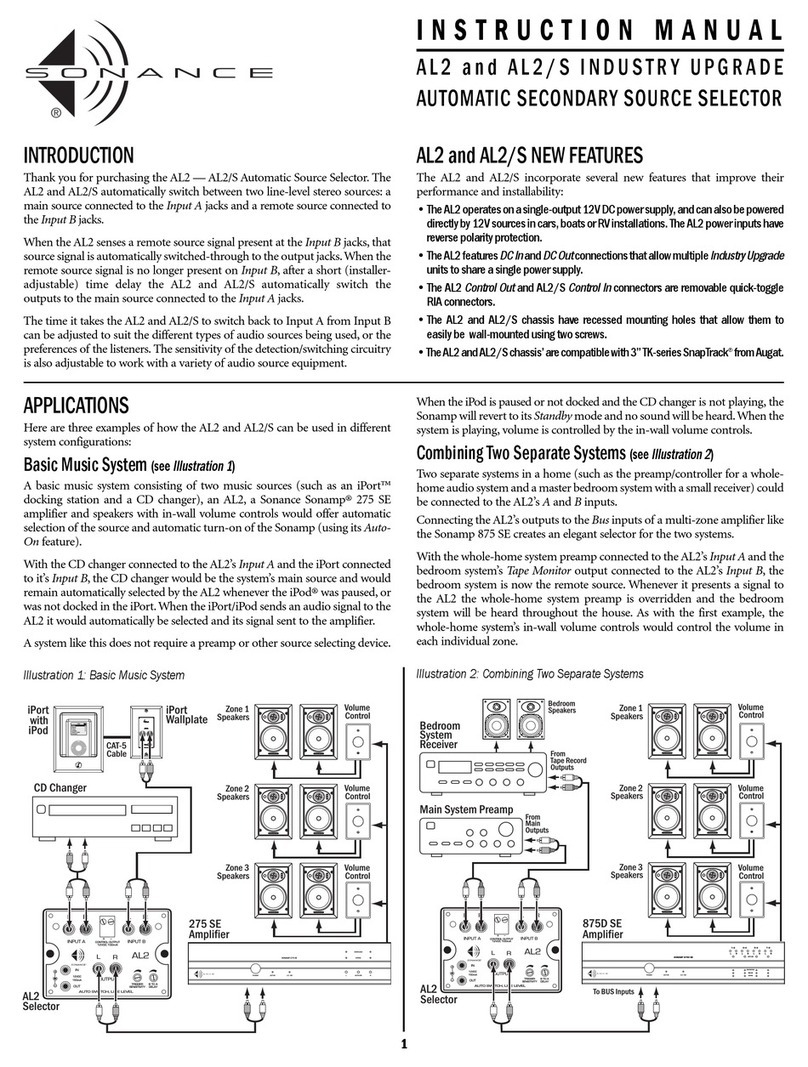

Table of contents

Other Moog Recording Equipment manuals

Popular Recording Equipment manuals by other brands

Leightronix

Leightronix LabVault-SD Installation, configuration, and operation manual

Fostex

Fostex G16S owner's manual

Unico

Unico DUAL PLUS 1C Manual of installation and use

DEVA Broadcast

DEVA Broadcast DB910 Quick user guide

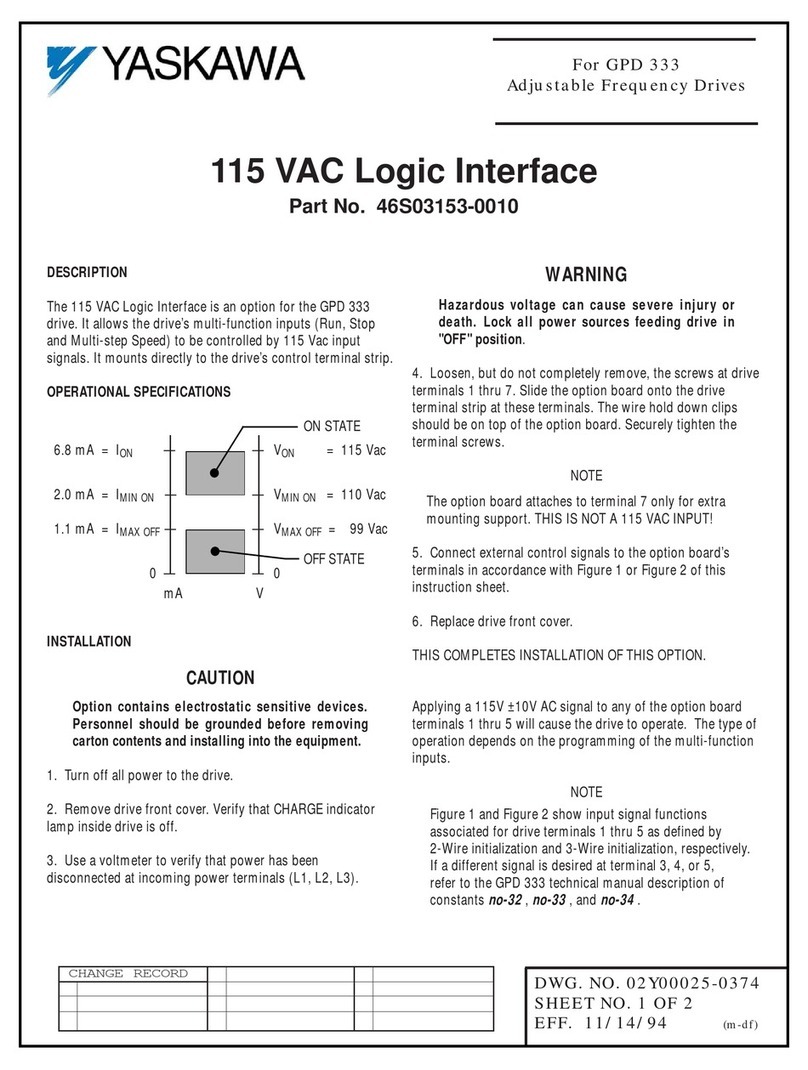

YASKAWA

YASKAWA 46S03153-0010 manual

Cabletron Systems

Cabletron Systems DELHF-UA user guide