Page 1

DPS

Introduction

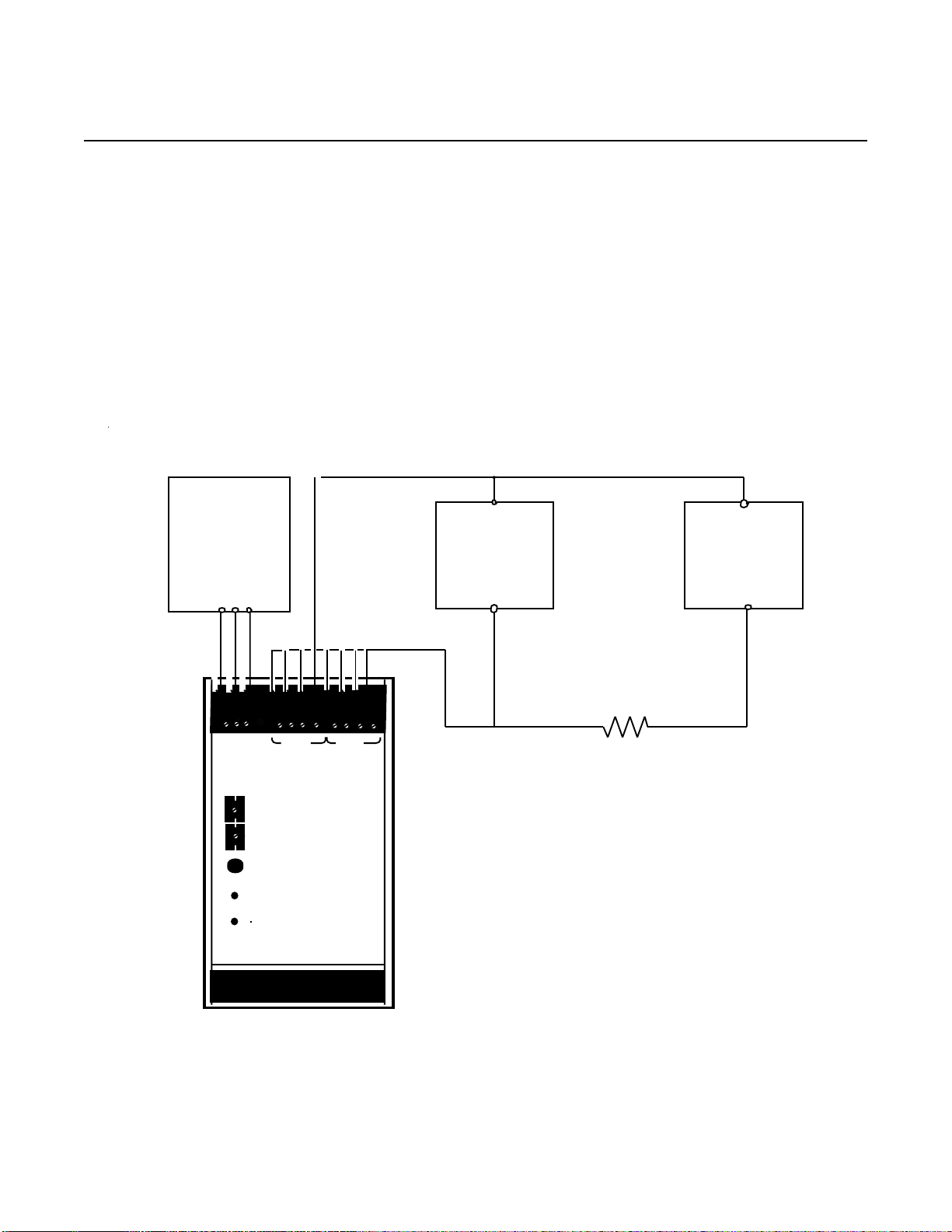

The DPS 240 is Moore Industries’ 240 milliamp (mA)

DIN-style Power Supply. It is a highly accurate, ad-

justable unit, most often used to power 2-wire trans-

mitters. It is also ideal for use with data

communications

modules like Moore Industries’ Link Converter Module

(LCM), or Redundant Link Module (RLM).

Unit features include continuous short circuit and

short-term overload protection, input/output isolation,

and a derated circuit design for added dependability.

This manual contains the description, specifications,

calibration information, and installation procedures for

the DPS 240.

Description

The DPS 240 is a compact unit; particularly well-

suited for use in industrial environments where avail-

able installation space is at a premium. It is enclosed

in a standard, DIN-style, aluminum housing de-

signed to be installed on a standard “G-rail” (not in-

cluded). This rail can then be mounted on a wall, in a

rack, or in a NEMA enclosure. Each DPS 240 is ca-

pable of powering twelve 4-20 mA loops.

The front panel of the the unit features potentiometers

for adjustment of voltage and current limit, test jacks

for auxiliary connection of calibration equipment, and

a red LED indicator that lights when dc output is

present.

The terminal blocks, three for input and eight for out-

put, can be set into either the front or rear panel, ac-

cording to customer specification.

The unit is available in 24- or 42-Vdc output configu-

rations. A potentiometer on the front panel allows for

adjustment of the output ±5.0%.

Input voltage can also be specified by the customer,

and is available set to 117, 220, or 240 Vac, 50/60

Hz.

The equipment specifications for the DPS 240

are listed in table 1.

Serial Number. A complete, serial-number-depen-

dent history is kept on every unit that Moore Indus-

tries sells and services. For service information,

provide the factory with the serial number of the unit

that requires

attention. The serial number is stamped on a label,

and affixed to the side panel.

Model Number. Moore Industries’ model numbers

identify the type of instrument, functional characteris-

tics, any options ordered, and the housing type. The

model number reflects the way the unit was config-

ured when it originally left the factory. It is all that is

needed to identify the operational characteristics of

the power supply. The number appears on the same

label as the serial number.

The following example outlines the significance of

each field in a typical DPS 240 model number.