SEA B 100 PLUS 1000N User manual

English

Operators for garage doors

Imported by SEA S.p.A.

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. +39 0861 588341 r.a. Fax +39 0861 588344

www.bleuteam.it

REV 00 - 12/2014

INSTALLATION MANUAL

B 100 PLUS

600N

B 100 PLUS

1000N

English

INDEX

1. FUNCTION DESCRIPTION.....................................................................................3

2. OPENER PACKAGE CONTENTS..........................................................................5

3. IMPORTANT INSTALLATION INSTRUCTION ..............................................................6

4. INSTALLATION STEPS.................................................................................................7

4-1. MEASURE DOOR’S HIGHEST TRAVEL POINT......................................................7

4-2. INSTALL HEADER BRACKET............................ ....................................................7

4-3. INSTALL DOOR BRACKET TO DOOR.................................................... ... ........8

4-4. ATTACH RAILTO OPENER HEAD...........................................................................8

4-5. ATTACH RAIL TO HEADER BRACKET....................................................................9

4-6. MOUNT OPENER TO CEILING......................... ..................................................9

4-7. CONNECTARM TO DOOR AND TROLLEY...................................................... 10

4-8. CHECK EMERGENCY RELEASE..........................................................................10

4-9. TENSION ADJUST ................................................................................................11

4-10. RAIL INSTALLATION.................. ..........................................................................11

5. CONTROL UNIT.......................................................................................................12

5-1. SAFETY AND CONTROL DEVICES CONNEXION......................13

5-2. CONTROL UNIT PROGRAMMING...............................................................13

5-3.TRANSMITTERS MEMORIZATION ................................................................13

5-4. RUN LEARNING.....................................................................14

5-5. THE ADJUSTMENT OF REVERSE FORCE .......................................................1. 4

5-6. USE PHOTOELECTRIC SWITCHES ..........................................................15

5-7. USE AUTOMATICALLY-CLOSING FUNCTION................................................. 15

6. TROUBLE SHOOTING ........................................................................................16

7. GENERAL NOTICE FOR THE INSTALLER AND THE USER .......................................17

REV 00 - 12/20142

In the event of a power cut all data remains permanently saved in the

program memory.

(End points, registered transmitters and the last position of the door.)

English

TECHNICAL DATA

TX Frequency:

230V/50Hz

140 170

120

4

600 1000

120

4

Standard

IP20

-20°C to +60°C

433.92 MHz

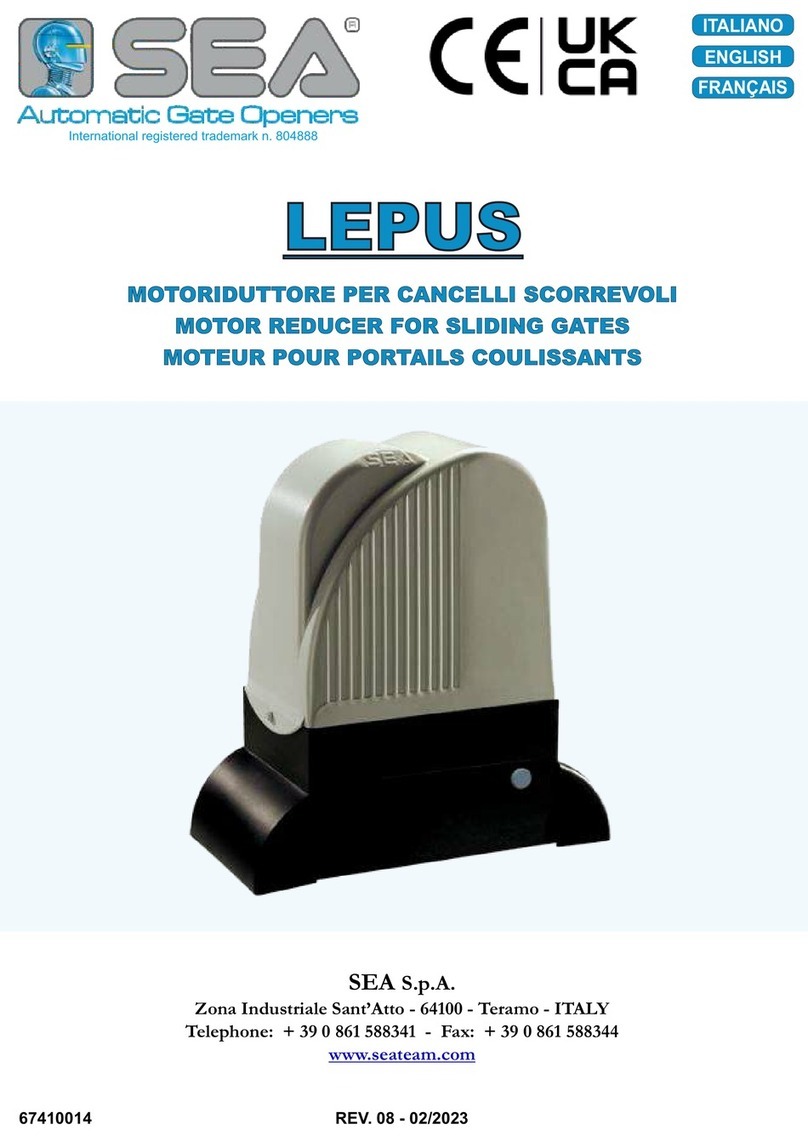

1. Functional description

The B 100 Plus 600N and B 100 Plus 1000N operators may be used for sectional doors.

Supply voltage:

Power(W):

Door (travel) speed(mm/s):

Maximum duty cycle(min):

Pulling force(N):

Internal release mechanism:

Protection category:

Permissible ambient temperature:

Data conservation:

Soft start

This function is integrated as a standard feature and guarantees a slow starting movement of the door.

Soft stop

With the aid of this function, the opener can slow down before reaching the final position.

Logic: OPEN - STOP - CLOSE - STOP - OPEN.

Additional connecting options for external accessories

In addition you can connect up external push buttons such as internal buttons, key switches and a wicket door contact.

Profile slide carriage

“Closed”

end position

“Open”

end position

Recognition of obstructions

The door opener has an automatic obstruction-recognition system (through internal monitoring of power).

If the door encounters an obstruction when closing or opening, the door opener stops the door automatically and moves it

approximately 10 cm in the opposite direction.

After removing the obstruction you can operate the garage door opener normally again.

REV 00 - 12/2014 3

B 100 PLUS

600N

B 100 PLUS

1000N

Internal release mechanism:

The models have an internal release mechanism with which you can open the garage door by hand in emergencies or in the event of

a power cut.

The internal release mechanism is attached to the profile slide with a rope and a knob. By pulling the rope you uncouple the garage

door from the opener and then you can open the door by hand.

It is suggested to:

• Close or open the door fully after each release.

• The emergency release is not intended for “everyday use”, since it is an emergency device..

Internal

release

mechanism

English

Rail and operators’ size

REV 00 - 12/20144

2. Opener package contents

The following items are included with the Garage Door Opener. The opener and rail are packaged with their respective

carton.

English

(A) OPENER

(B)ACCESSOIRES

a. Wall Bracket (1x)

b.D. oor Braket & Plate (1x)

c. U Bracket (3x)

e. Clevis (1x)

f. Clevis (1x)

g. Cotter pin (3x)

h. Hex nut (1x)

i. Hex bolts (1x)

k. Hex Head Driving Screw (4x)

(C) Straight DoorArm

(D) Curved DoorArm

(F) Rail

REV 00 - 12/2014 5

3. Important installation instructions

WARNING

1. READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS

2. Check with the door manufacturer to determine if additional reinforcement is required to support the door prior to

installation of the garage door opener.

3. Install garage door opener only on a properly balanced garage door .An improperly balanced door could cause

seriously injury. Have a qualified service person make repairs to garage door cables, spring assemblies, and other

hardware before installing the opener.

4. Remove all ropes and disable all locks connected to the garage door before installing opener.

6.

After installing the opener, test Safety Reversal System. Door MUST reverse when touching an obstacle, within the

time and ways described in the regulations.

English

5. Do not connect the opener source of power until you have performed all the steps of these instructions.

7. Once a year: keep well lubricated rollers of the door, the hooks and the bearings following the instructions or

contacting a maintenance company.

REV 00 - 12/20146

4. INSTALLATION STEPS

Identify a sound structural support on header wall above garage door for header bracket mounting.

Fasten it securely using lag screws (not provided) to structural supports of garage.

4-1. Measure door’s highest travel point:

• Open door to its highest travel point and measure from the garage floor to the top of door.

• Write down this distance.

Add 30mm to the door travel height (measured above).

English

4-2. Install header bracket

! WARNING!

If the header bracket is not rigidly fastened to a sound structural support on the header wall or ceiling, the safety

reverse system may not work and could cause accidents and serious injuries. DO NOT move or adjust springs or

garage door hardware, as these parts are under extreme tension and could cause accidents or serious injuries.

REV 00 - 12/2014 7

4-3. Install door bracket to door

Mark the position of the holes and fix the anchor bracket to the upper end of the door with screws (not supplied).

4-4. Attach rail to opener head

!WARNING!

When fastening the rail to the opener, use only the screws provided. Use of any other screws may result in

opener falling from ceiling and causing damage to persons or property in the garage.

• Position rail onto opener chassis by lining up rail sprocket opening with motor head shaft (see drawing 4-4-1).

Make sure shaft engages teeth inside rail sprocket.

• Position 2 “C” rail clips over rail and onto chassis. Flanges on “C” rail clips MUST fit into guide posts recesses (see

drawing 4-4-2)

English

• Insert screws (k) through bracket holes and into chassis holes, and tighten screws firmly to hold rail to head (see

drawing 4-4-3).

4-4-1 4-4-2 4-4-3

REV 00 - 12/20148

4-5. Attach rail to header bracket

• Support opener head slightly off the floor.

• Lift the opposite end of the rail up to the header bracket.

• Position rail end-stop within the openings in the header bracket. Insert clevis (e), and then attach cotter pin (g) to

end of pin.

English

4-6. Mount opener to ceiling

!WARNING!

If not properly secured, the operator could fall and injure someone. Secure opener to structural supports or framing. Do

not mount to drywall, plaster, or other such material.

• Position opener head so that rail is lined up with center line of open door.

• Line up hanger brackets (not provided) with ceiling joists or framing to locate where brackets are to be fastened.

With two screws, 2 nuts and a u-shaped hoop will orbit on fixed to a hanger.

REV 00 - 12/2014 9

4-7. Connect arm to door and trolley

• Make sure door is fully closed.

• Pull the manual release cord on the trolley to disconnect trolley from chain or belt connector.

Slide trolley to position it about 100mm-200mm away from the door.

• Will push-pull crotch fixed on the door fittings, see figure.

Fig.4-7-1

English

• After connecting appropriate door arm, ensure trolley is disengaged. Check for proper door operation by manually

lifting then lowering to fully opened and closed positions.

• Readjust door arm if needed.

Pull down on release knob to lock trolley, then move door manually until trolley locks with chain or belt connector.

4-8. Check emergency release

!WARNING!

Use extreme care when pulling release knob. DO NOT use knob to pull door open or closed. Except for

emergency situations, use knob only when door is closed.

The emergency release cord with red knob, which is already attached to the trolley, is extremely important parts

of the operator system; see drawing 4-7-1, pulling the release cord disengages the door from the opener. This

allows the door to be moved manually up and down independent of the opener motor.

If the door is in the open position, use extreme care when using the release.

Use emergency release to disconnect the door if the power is out. It should also be used if for some unforeseen reason

the door strikes a person or object during its travel and does not automatically reverse off the obstruction.

To release door- pull firm ly down on red knob.

Prior to re-engaging door, ensure that all obstructions are removed and door is operating properly manually. Before

re-engaging trolley with a chain or belt connector, pull down knob again, then release. The red catch will stop in the

“lock” position and will open indicator window. Now the door can be reconnected by moving it manually and bringing

it into position when the connector is inside of the trolley.

REV 00 - 12/201410

4-9. Tension adjust

The tension, can the adjusting screw clockwise until brush and the rail has the right position.

English

4-10. Rail installation

1 , 2 Rail end, 3 4 Rail, 5 Slider, 6 B , 7

8 9 chain, 10 11 12 13 14

15 16 17 18

Lock nut Party neck bolt, lock Self-tapping screws,

spring, Pulley block, Slippery wheel, pulley, bars, Shake hands

handle, Spring, Link head, Sprocket stents, Sprocket

REV 00 - 12/2014 11

5. Control unit

CN1

CNE

CNR

SD

MR

ML

POWER LIGHT

BATTERY

DISPLAY

RECEPTOR

+ -

+24V PB GND

PBSW

+ Allarm -

A-SW

CN1 = Input/output connector

CNE = Encoder connector

CNR = External receiver connector

SD = Door contact

MR = Right motor

ML = Left motor

POWER = Power supply connector

BATTERY = Battery connector

LIGHT = Courtesy light connector

DISPLAY = Display connector

English

REV 00 - 12/201412

WAL L

SWITCH

English

5-1. Control and safety devices connection

wiring method: CN1

PUSH

GND

SAFETY

+24V

TXRX

+24V

PB

GND

PBSW

Function logic:

OPEN - STOP - CLOSE - STOP - OPEN.

Note:

+24V accessoires power supply

GND accessoires negative

PB photocells contact

PBSW START contact

5-2. Control unit programming

5-3. TX Memorization

If you need to learn another remote control, reprogram as the step 1), the opener can study 20 remote controls at most.

2) TX Cancellation

Powering the unit you may see scrolling

the numbers from 9 to 1 on the display. If

the numbers appear reversed,

immediately press the button setting and

the numbers will be reversed and

displayed in the correct manner.

Press and keep pressed “CODE”

until the decimal point “.” is bright

and then off automatically.

Release “CODE”, all

memories are erased.

1)

Press “CODE” over one second,

until the LED display dot “.”, is

brightened.

Press any button of remote control once,

the decimal point “.” is off automatically.

Press this remote control buttons again, the dot“.” flashes quickly.

After the decimal point“.” off, which indicates the successful

learning of remote control.

Suggestions: For the sake of safety, once the remote control is lost, please erase all the memories of remote control,

and study it again.

REV 00 - 12/2014 13

English

5-4. Run learning

Press “SETTING” over 4 seconds

until the LED displays the letter “1”.

It turns into opening position learn

state.

Press “+” (OPEN)

until the door is not in

the desired open

position.

During this phase the

display displays the

letter “n”..

When the door reaches to the desired

position, leave “+” press “SETTING” to

confirm the opening position. The

LED displays the letter “2”. It turns into

closing position learn state.

Press “-” (CLOSE),until the door is

not in the desired closed position.

During this phase the display

displays the letter “u”..

When the door reaches to the desirable position, leave

press “SETTING” to confirm the closing position. After

finishing setting, the LED will display “ll”, and the door

can operate normally.

“-

”

NOTE: and the door moves in closing, exchange the motor cables.If press button “+”

Press “SETTING” until the LED displays

the letter “3” and release button.

Use “+” (OPEN) to increase

the force, press“-” (CLOSE) to decrease.

The LED displays the of setting.value

Once found the right value, press SETTING to

confirm. After finishing setting, the LED displays

“ll”.

5-5. The adjustment of reverse force

REV 00 - 12/201414

5-6. Use photoelectric switches

The photocell input can be disabled through the display.

English

If you want the photocell active, press "+" (OPEN) until

the LED displays "H".

If you want the photocell not active, press the "-"

(CLOSE), the LED displays "II".

When finishing the setting, press “SETTING” to quit,

digital shows “II”.

5-7. Use automatically-closing function

Press “+” (OPEN) over 4 seconds,

the LED displays “-”, you can set

Automatically–closing function.

Press “+” (OPEN), or “-” (CLOSE)

to adjust automatically closing

time.

When set up is completed, press

“SETTING” to confirm and exit.

Emergency stop

connection

It is possible to connect on

the CN2 terminal a battery

for the emergency

operation. Connect a 12V

max 2Ah battery (charge

current 150mA).

The closing time will vary

from 1 to 9 min. in steps of 1

min.

"0" indicates that the

automatic reclosing is

OFF.

Press “-” (CLOSE) over 4 seconds until

the LED displays “-”, you can set the he

status of the photocells.

REV 00 - 12/2014 15

6. Trouble shooting

Fault Cause Solution

English

Check the electrical

outlet and/or the

powder supply fuse

Re-adjust the journey

No response for the

operator, LED is off

Disconnection between

door opener and power

supply

No response for the

operator

The journey adjustment

is wrong

While opening or closing

doors, it stops in the

middle on its way, or

runs at opposite way

The door operating

resistance is stronger

than the set force

- Check the balance

system of the door

- Readjust the opener to

increase the load force

of the door

The door cannot be

closed

The photoelectric switch

is sheltered from the

obstacle

The photoelectric is

not connected

Remove the obstacle

Connected the

photoelectric

The door cannot be

opened or closed

completely

The journey of the door

is adjusted

inappropriately

Re-adjust the journey

of door opener

REV 00 - 12/201416

English

7. GENERAL NOTICE FOR THE INSTALLER AND THE USER

1. Read carefully these Instructions before beginning to install the product. Store these instructions for future

reference.

2. Don’t waste product packaging materials and /or circuits.

3. This product was designed and built strictly for the use indicated in this documentation. Any other use, not

expressly indicated here, could compromise the good condition/operation of the product and/or be a source of

danger. BLEU by SEA declines all liability caused by improper use or different use in respect to the intended

one.

4. Once installed, the products BLEU by SEA must comply with the Machinery Directive (2006/42/EC and

subsequent amendments).

Installation must be done respecting Directives: EN12453 and En12445.

5. Do not install the equipment in an explosive atmosphere.

6. BLEU by SEA is not responsible for failure to observe Good Techniques in the construction of the locking

elements to motorize, or for any deformation that may occur during use.

7. Before attempting any job on the system, cut out electrical power and disconnect the batteries. Be sure that

the earthing system is perfectly constructed, and connect it metal parts of the lock.

8. Use of the indicator-light is recommended for every system, as well as a warning sign well-fixed to the frame

structure.

9. BLEU by SEA declines all liability as concerns the automated system’s security and efficiency, if

components used, are not produced by BLEU by SEA.

10. For maintenance, strictly use original parts by BLEU by SEA.

11. Do not modify in any way the components of the automated system.

12. The installer shall supply all information concerning system’s manual functioning in case of emergency,

and shall hand over to the user the warnings handbook supplied with the product.

13. Do not allow children or adults to stay near the product while it is operating. The application cannot be used

by children, by people with reduced physical, mental or sensorial capacity, or by people without experience or

necessary training. Keep remote controls or other pulse generators away from children, to prevent involuntary

activation of the system.

14. Transit through the leaves is allowed only when the gate is fully open.

15. The User must not attempt to repair or to take direct action on the system and must solely contact qualified

BLEU by SEA personnel or BLEU by SEA service centers. User can apply only the manual function of

emergency.

16. The power cables maximum length between the central engine and motors should not be greater than 10

2

m. Use cables with 2,5 mm section. Use double insulation cable (cable sheath) to the immediate vicinity of the

terminals, in particular for the 230V cable. Keep an adequate distance (at least 2.5 mm in air), between the

conductors in low voltage (230V) and the conductors in low voltage safety (SELV) or use an appropriate sheath

that provides extra insulation having a thickness of 1 mm.

REV 00 - 12/2014 17

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

REV 00 - 12/201418

Dichiarazione di conformità

Declaration of Conformity

Prodotto: B 100 PLUS 600N - B 100 PLUS 1000N

Importato da paesi extra UE da:

Imported by extra UE countries by:

SEAS.p.A.

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. +39 0861 588341 r.a. Fax +39 0861 588344

La SEA S.p.A. dichiara che i prodotti sopra citati sono conformi ai requisiti essenziali di sicurezza relativi

ai prodotti entro il campo di applicabilità delle seguenti Direttive Comunitarie:

SEA S.p.A. declares that the above mentioned products are conforming to the essential safety

requirements related to the product within the field of applicability of the following Community Directives:

- Direttiva 2006/42/CE Direttiva macchine (allegato I)

Directive 2006/42/CE Machinery Directive (annex I)

- Direttiva 2004/108/CE Direttiva compatibilità elettromagnetica

Directive 2004/108/CE Electromagnetic compatibility

• CEI EN55014-1 Emissioni condotte e radiate

IEC EN55014-1 Conducted and radiated emissions

• CEI EN55014-2 Prove di immunità

IEC EN55014-2 Magnetic field immunity

- Direttiva 2006/95/CE - Direttiva Bassa Tensione

Directive 2006/95/CE - Low voltage Directive

• CEI EN60335-1:2008 Sicurezza degli apparecchi elettrici d’uso domestico e similare (Requisiti

Generali).

IEC EN60335-1:2008 Houseold and similar electrical appliances - Safety - Part one: general

requirements.

(Luogo, data di emissione) L’Amministratore

(Place, date of issue) The Administrator

Teramo, 23/12/2014 Ennio Di Saverio

http://www.seateam.com

Imported by SEA S.p.A.

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. +39 0861 588341 r.a. Fax +39 0861 588344

www.bleuteam.it

This manual suits for next models

1

Table of contents

Other SEA Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

Automatic Technology

Automatic Technology GDO-6 EasyRoller owner's manual

SOMFY

SOMFY Elixo 500 230 V installation manual

Steel-Line

Steel-Line SD800 Installation and operating instructions

Wisniowski

Wisniowski AWso2018 Assembly and operating instructions

B&D

B&D Series 2 Firmadoor installation instructions

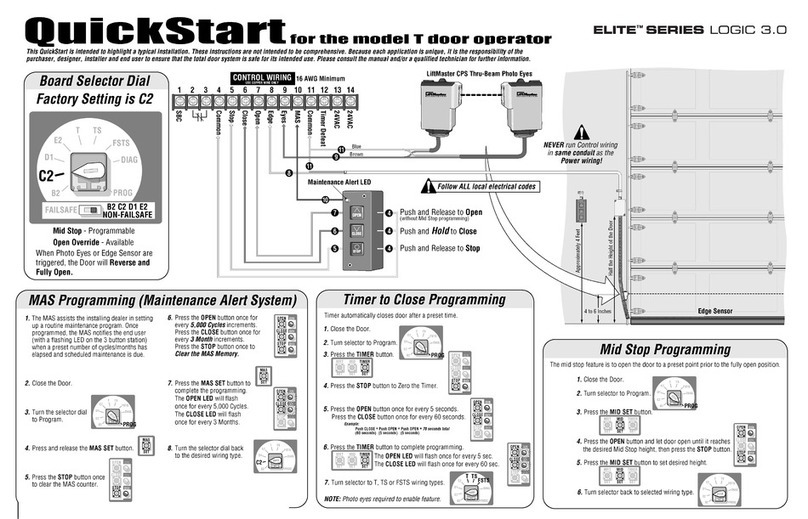

Chamberlain

Chamberlain T quick start guide