3. INSTALLATION

3.a Regulations

The use of gas devices is controlled by precise regulations.

Installation of liquified petroleum gas (L.P.G) must comply with all

the manufacturer’s requirements and those of the regulations.

3.b Wall mounting

Warning

Do not install this device in an area that contains dust, greasy

vapour and/or corrosive elements.

- The device must be installed on a suitable wall surface that

allows the fitting of a vertical exhaust gas flue

- It is vital to leave the minimal distances around the device as

shown in fig 4 to allow for maintenance operations to take place.

Location

The water heater requires a plentiful supply of fresh air for correct

operation. Fixed ventilators or air inlets should not be obstructed.

Do not install the water heater in a location where incomplete

combustion is foreseeable such as bathrooms or bedrooms unless

specifically allowed by national legislation.

The minimum low and high level free ventilation areas are stated

on this page and must be observed.

The water heater must be fixed to a load bearing wall in a vertical

plane.

3.c Room ventilation

The installation of the water heater must comply with regulations in

force including any updates. See page 3

Warning: This device can only be installed in venues that are

permanently ventilated according to regulation in force.

• COMBUSTION GAS REMOVAL

A single wall vertical flue pipe of Ø110mm must be used and when

it passes through combustible materials, a metal sleeve of

Ø170mm must be used to allow an air gap of 25 mm. Part code

FTFCTG101.

Flue pipes and terminals should comply with BS 715. Terminals

shall not be sited within 300 mm. of a ventilator or open window. In

the U.K. full details of flueing requirements are given in BS EN 1949.

The overall length of the flue must be 600mm from the bottom of

the terminal louvres to the top of the water heater. At least 250mm

of this length must be external to the roof through which it is fitted.

• AIR SUPPLY FOR COMBUSTION

Air requirements: Reference is made to BS 5482 (BS EN 1949) and

EN 721 covering ventilation requirements for permanent dwellings,

caravans and boats.

Fixed ventilation should be provided to avoid draughts as far as

possible without impairing the free area of ventilation, even in ad-

verse weather conditions. If the heater is positioned in location

which may be subjected to strong draughts i.e. close to a window

or opening then strong draughts or gusts of wind may extinguish the

pilot.

All permanent openings for ventilation should be designed to pre-

vent the entry of vermin. Where screens are provided, they should

not have apertures of less than 6 mm. or greater than 9 mm. in any

direction, and they should be accessible for cleaning. Fine mesh screens

shall be avoided as they are liable to become blocked with dust.

The location of vents and the method of cleaning them should be

stated in the Owners Handbook (Caravans and Boats).

As a guide, the minimum effective free area of vents is stated below

in connection with this water heater. Additional appliances burning

gas in the same area would require additional ventilation.

If the appliance is installed in an enclosed cupboard in a Caravan

Holiday Home the required ventilation is that specified in BS 5482

part 2 and BS EN 1949, i.e. 10 cm² per kilowatt input rating divided

between high and low. Each of the high and low vents should

therefore be 109 cm² of free area.

3.d Gas Connection

The water heater should be connected to the gas supply via a

15mm diameter copper gas pipe. A gas isolation valve must be fit-

ted to the gas inlet on the water heater.

When installing or commissioning the water heater the following

must be observed:

- The diameter of the gas pipe between the supply bottle or tank

must be in accordance with the regulations in force

- The regulator size and pressure specification are correct for the

application

- The correct gas (LPG) is being supplied

- All the required gas pressure and tightness tests are carried out

as part of the commissioning process.

- Gas joints downstream of the magnetic gas valve must be

checked with leak detection fluid while the heater is running

- Gas jointing paste should not be used when connecting the gas

isolation valve

Do not obstruct the area’s ventilation openings where the device is

installed to avoid dangers such as the build-up of toxic and explosive

gases.

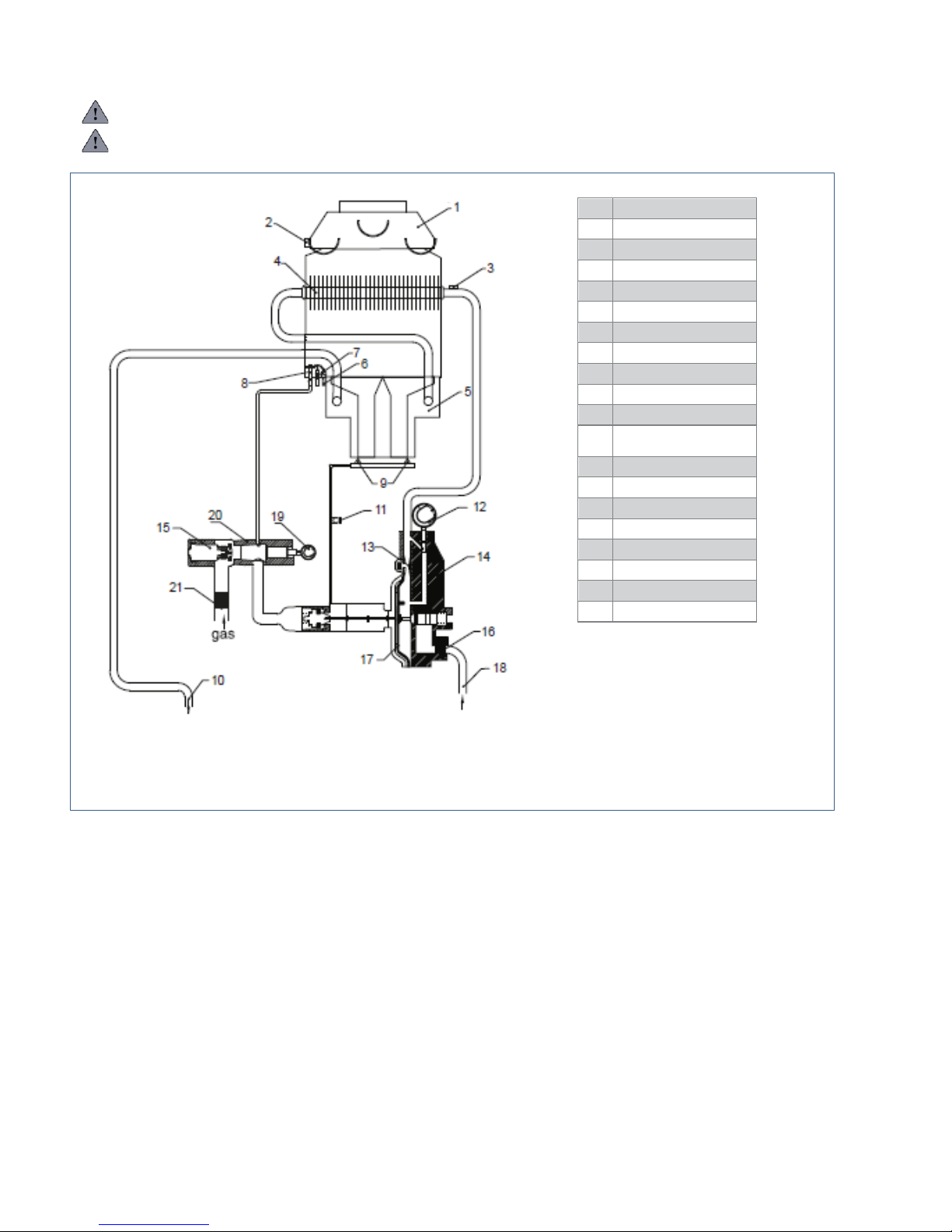

ATTENTION: if the appliance is supplied with G31@50 mbar,

remove the protective cap (pos. 10 water heater components pag.

7) and regulate the pressure screw so that the burner reaches the

pressure indicate in the technical data.