1

Morrison Bros. Co. ‑ Dubuque, IA ‑ 800‑553‑4840

918‑‑‑0188 PP

3-10-17

!

!

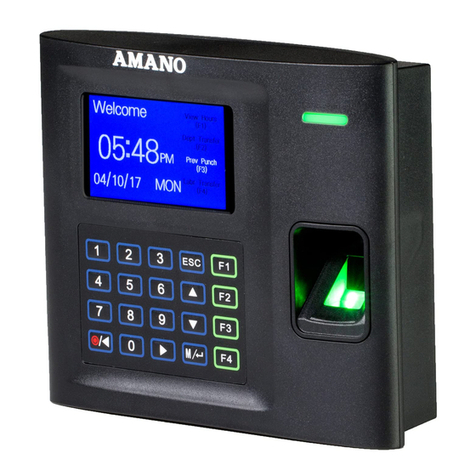

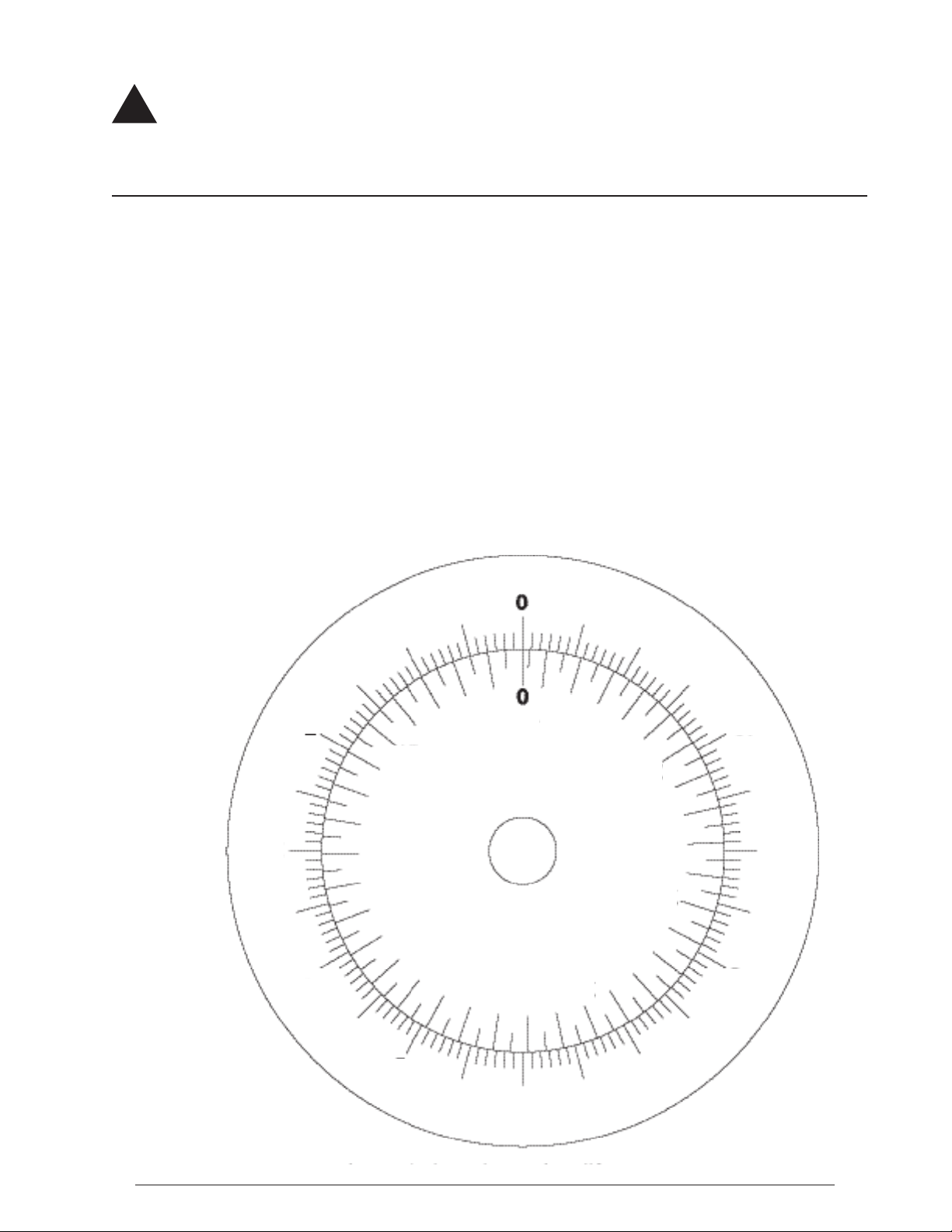

The 918 Clock Gauge is designed to measure liquid level in an aboveground storage tank. The gauge mounts on

top of the tank and is activated by a oat connected to a cable. The 918 is designed to connect to an alarm box

that can provide a high level audible alarm at a desired volume that is set during installation.

Failure to follow any or all of the warnings and instructions in this document could result in a hazardous

liquid spill, which could result in property damage, environmental contamination, re, explosion, serious

injury or death.

NOTE: The most accurate method to calibrate the tank is with uid in it. This will take into account variables

associated with the oat position, the mechanism, and the uid density.

NOTE: Switch contact rating: 125V AC/30V DC, 1 Amp maximums

Gauge Installation & Calibration

WARNINGS

• Fire Hazard – Death or serious injury could result from spilled liquids.

• You must be trained to install or maintain this alarm. Stop now if you have not been trained.

• Any modication to this gauge other than those stated in these installation instructions will void the product

warranty.

• This device is intended to be used as an auxiliary warning to the operator of a possible overll situation and

should not be the only system in place to prevent a tank from overlling. It is the sole responsibility of the

operator to continuously prevent any spillage regardless of the situation or status of the gauge.

• Install in accordance with all applicable local, state, and federal laws.

• For your safety, it is important to follow local, state, federal and/or OSHA rules that apply to working inside,

above, or around the storage tank and piping area. Use all personal protective equipment required for working

in the specic environment.

• Tanks could be under pressure. Vapors could be expelled from tank vents, piping, valves or ttings while

performing installation. Vapors could catch re or cause an explosion. Avoid sparks, open ame, or hot tools

when working on gauge.

• Use a dampened cloth when cleaning the clear front cover of the gauge or 918 alarm box to prevent static

buildup and discharge.

• In the event of malfunction, contact Morrison Bros. Customer Service.

Steps

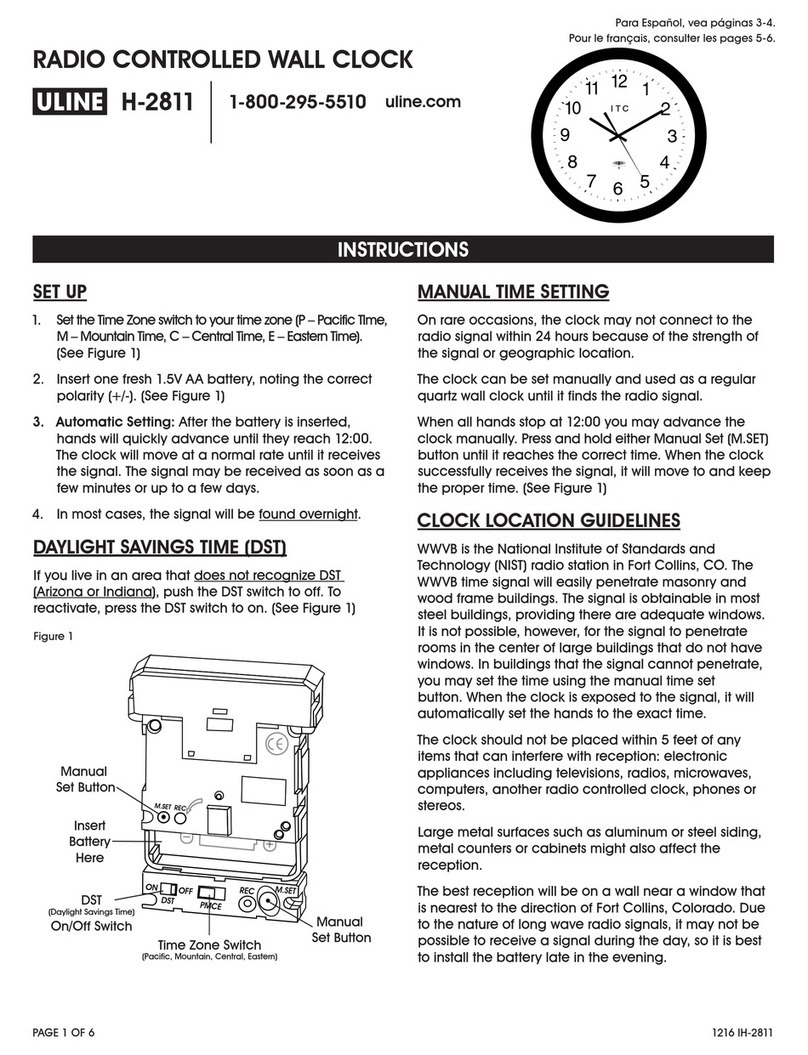

1. Verify contents of box. You should have received the gauge, oat, installation instructions, re-order/overll

labels, warning tag, cable tie, and optionally the alarm box. Inspect the items for shipping damage. DO NOT

use if damage is found. DO NOT pull and release the cable uncontrollably. This can cause damage to the in-

ternal mechanism and render the gauge inoperable. ALWAYS hold onto cable and allow it to move in a slow

steady motion.

2. Locate the opening, on the top of the tank, where the gauge is to be installed. If possible, select a location

away from the ll port to avoid excessive turbulence that could affect the oat. Also make certain that there

are no objects inside the tank, near the selected opening, upon which the oat and cable could get tangled.

3. Once an opening is selected, measure to the bottom to determine the current liquid level height in the tank.

Record this height in feet and inches (or meters and cm) as you will need it to set the gauge once it is in-

stalled.

4. Apply pipe dope or Teon tape to the male threads on the gauge. If you have a gauge with female threads,

apply the pipe dope or Teon tape to the male threads of the pipe on the tank. DO NOT get pipe dope on the

cable of the gauge.

5. Open the oat clip and attach the oat clip to the swivel end of the cable. Latch the oat clip making sure the

oat clip is securely closed.

918 Clock Gauge

Installation, Operation, and Maintenance Instructions