I

g_

MASKINFABRI

HARALDSVEJ21

DK-8900

RANDERS

TLF.

+ 4586435155

FAX.

+ 4586435100

Instructions

manual

MORS0

Mitringmachine

Model

F

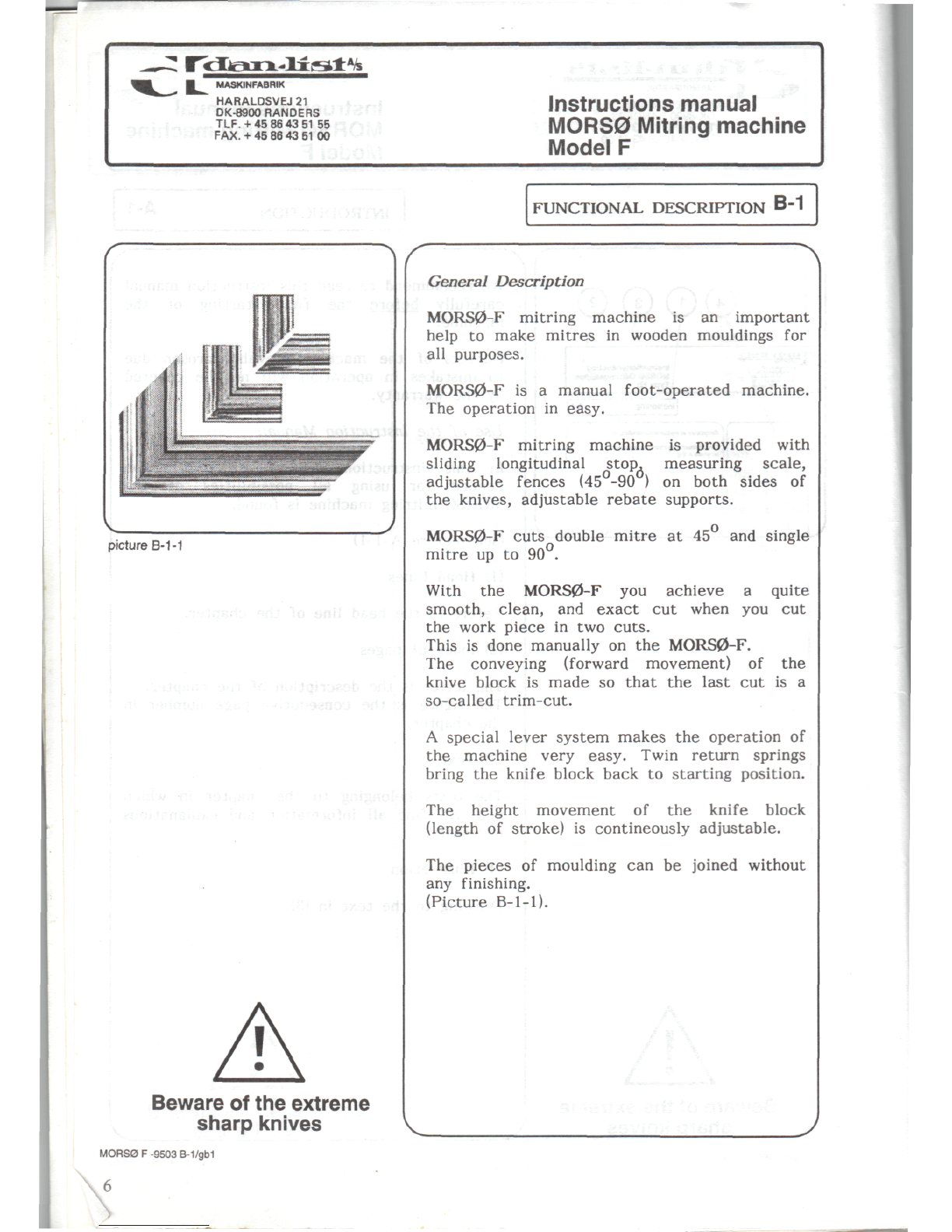

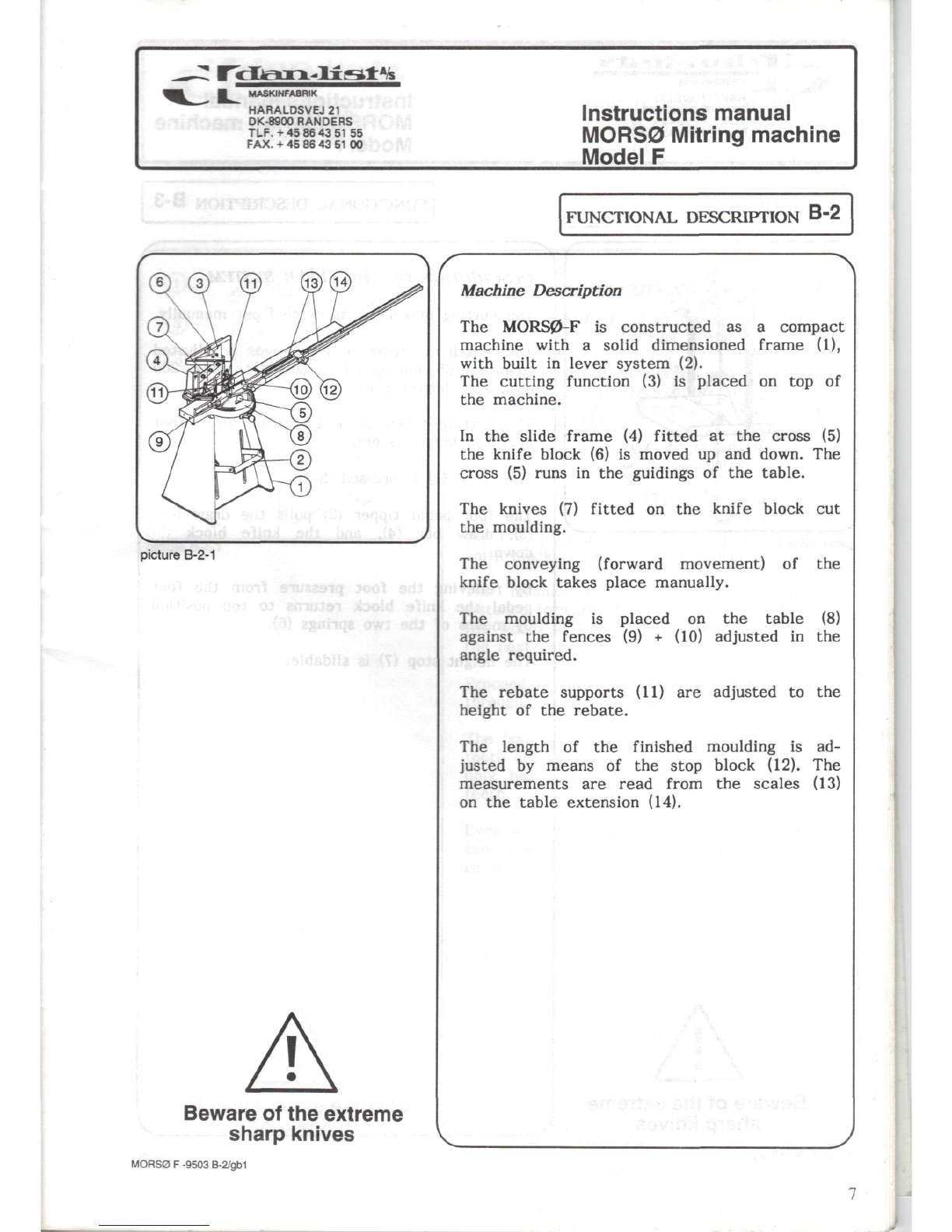

picture

B-1-1

FUNCTIONAL

DESCRIPTION

B-1

Beware

of

the

extreme

sharp

knives

General

Description

MORS0-F

mitringmachine

isan

important

help

to

make

mitres

in

woodenmouldings

for

all

purposes.

MORS0-F

isa

manualfoot-operatedmachine.

The

operation

in

easy.

MORS0-F

mitringmachine

is

providedwith

sliding

longitudinalstop,measuring

scale,

adjustable

fences

(45°-90

) on

both

sides

of

the

knives,adjustable

rebate

supports.

MORS0-F

cuts

double

mitre

at45and

single

mitre

upto

90°.

With

the

MORS0-F

you

achieve

a

quite

smooth,clean,

and

exact

cut

when

youcut

the

work

piece

intwo

cuts.

This

is

donemanually

onthe

MORS0-F.

The

conveying

(forward

movement)

ofthe

knive

block

is

made

so

that

the

last

cutisa

so-called

trim-cut.

A

special

lever

system

makes

the

operation

of

the

machinevery

easy.

Twinreturnsprings

bring

the

knife

blockback

to

startingposition.

The

heightmovement

ofthe

knife

block

(length

of

stroke)

is

contineouslyadjustable.

The

pieces

of

moulding

canbe

joinedwithout

any

finishing.

(PictureB-1-1).

MORS0

F

-9503

B-1/gb1