MORTEX PRODUCTS INC. 501 TERMINAL RD FORT WORTH, TX 76106 Page 10

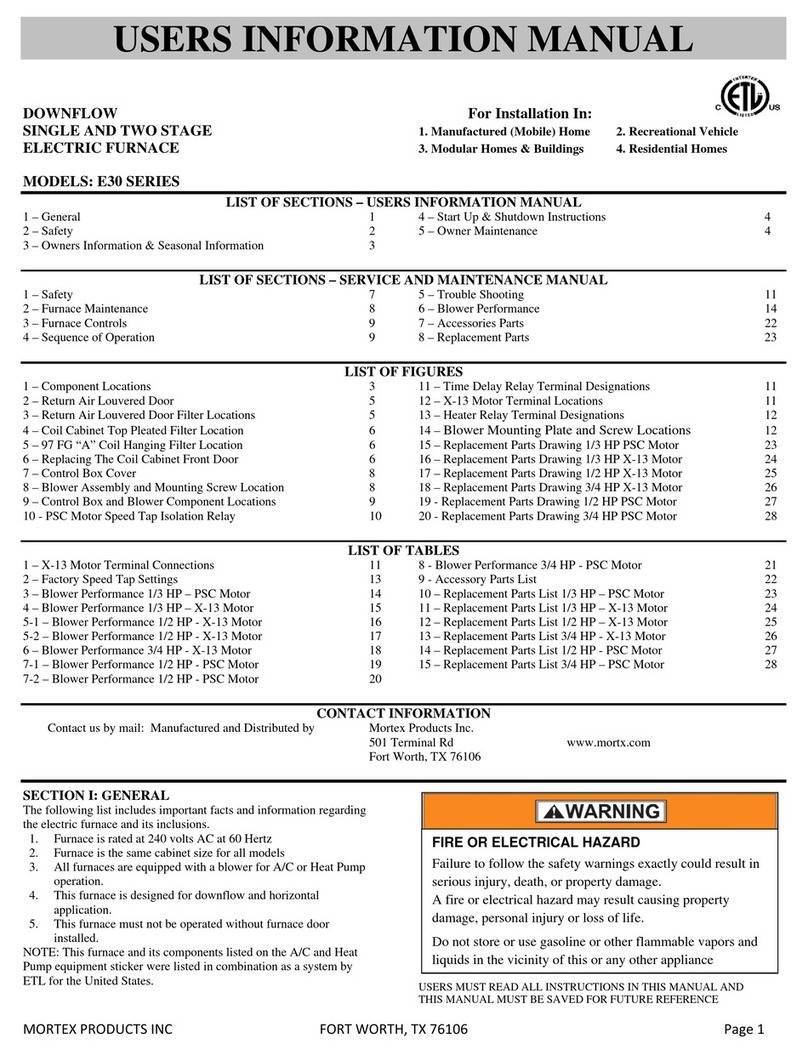

SECTION 8: LINE VOLTAGE WIRING

The furnace internal wiring is complete except for the 208/240

VAC power supply and the thermostat wiring. See wiring diagram

and Tables 6 and 7 for wire size, fuse/circuit breaker size, and

ground wire sizes. Power wires can enter through the right side of

the furnace or through the auxiliary entrance located in the bot-

tom of the furnace. When bringing wiring through the side of the

furnace, a cable connector (strain relief) must be installed to hold

wiring in place and to relieve any strain on the wiring.

Single Electrical Power Supply – 5kW, 6kW, 8kW, 10kW

Electric Heat

1. Remove the furnace front access panel.

2. Remove the control box cover.

3. Install a cable connector (strain relief) in the 7/8” (22.2 mm)

diameter hole on the right side of the control box.

NOTE: Do not install the cable connector in the furnace

exterior cabinet hole in the as the sheet metal gauge is too

thin.

4. Strip ½” (12.7mm) of the insulation on the end of each wire.

5. Insert the incoming power supply cable through the hole in

the left side of the casing and through the cable connector.

6. Insert the BLACK wire into the L1 screw terminal on the

circuit breaker and tighten the setscrew until the wire is

securely fastened to the circuit breaker screw terminal.

7. Insert the WHITE or RED wire into the L2 screw terminal on the

circuit breaker and tighten the setscrew until the wire is

securely fastened to the circuit breaker L2 screw terminal.

8. Insert the GREEN ground wire into the ground lug and tighten

the set screw until the ground wire is securely fastened to the

ground lug.

9. Once all of the wiring connections have been made, secure the

incoming power supply cable by tightening the cable

connector around the incoming power supply cable.

10. Refer to Table 6 for the required wire size and required

overcurrent protection (fuse/circuit breaker) size.

Single Electrical Power Supply - 12kW, 15kW, 20kW

Electric Heat

1. Remove the furnace front access panel.

2. Remove the control box cover.

3. Install a cable connector in the 7/8” (22.2 mm) diameter hole on

the right side of the control box.

NOTE: Do not install the cable connector in the furnace exterior

cabinet hole in the as the sheet metal gauge is too thin.

Installation of surge protection circuit breakers is

recommended to prevent supply line power surges to the

furnace. Power surge protection is designed to prevent

voltage spikes that can cause damage to heater contactors

and limit controls. Voltage spikes can weld the contacts of

heat contactors, relays and limit controls closed preventing

them from opening. Welded heat contactor or heat relay

contacts will result in the electric heaters remaining ON after

the blower motor turns o following the end of a heat cycle.

Welded limit control contacts will prevent the limit control

from opening in an overtemperature condition due

to insucient air-ow. Either condition can result in a

hazardous condition which may cause a re, loss of

property or loss of life.

4. Strip ½”(12.7mm) of the insulation on the end of each wire.

5. Insert the incoming power supply cable through the hole in the

right side of the casing and through the cable connector.

6. Insert the GREEN ground wire into the ground lug and tighten

the set screw until the ground wire is securely fastened to the

ground lug.

7. Using Jumpers to Connect Power Supply to Stage 2

Circuit Breaker.

a. Insert the BLACK jumper wire along with the incoming

BLACK power supply wire into the L1 screw terminal on the

top (stage1) circuit breaker and tighten the set screw until

the wires are securely fastened to the top circuit breaker L1

terminal.

b. Insert the other end of the BLACK jumper wire into the L1

screw terminal on the bottom (stage 2) circuit breaker and

tighten the set screw until the wire is securely fastened to

the bottom circuit breaker L1 screw terminal.

c. Insert the WHITE or RED jumper wire along with the

incoming WHITE or RED power supply wire into the L2 screw

terminal on the top (stage 1) circuit breaker and tighten the

set screw until the wires are securely fastened to the top

circuit breaker L2 terminal.

d. Insert the other end of the WHITE or RED jumper wire into

the L2 screw terminal on the bottom (stage 2) circuit breaker

and tighten the set screw until the wire is securely fastened

to the bottom circuit breaker L2 screw terminal.

e. Once all of the wiring connections have been made, secure

the incoming power supply cable by tightening the cable

connector around the incoming power supply cable.

f. Refer to Table 6 for the required wire size and required

overcurrent protection (fuse/circuit breaker) size.

8. Using Jumper Bar Assembly to Connect Power Supply to

Stage 2 Circuit Breaker

NOTE: Use 100-amp 4 Pole Jumper Bar Assembly Part

Number 68BAE001.

a. Remove the jumper bar cover by removing the 2 screws that

secure the cover to the assembly.

b. Insert the 4 copper tabs on the jumper bar assembly into

the L1 and L2 screw terminals on both of the top and

bottom circuit breakers. Tighten the set screws on the screw

terminals until the tabs are securely fastened to all 4 of the

circuit breaker screw terminals.

c. Insert the incoming BLACK power supply wire into the L1

screw terminal on the jumper bar assembly and tighten the

set screw until the wire is securely fastened to the L1 screw

terminal.

d. Insert the incoming WHITE or RED power supply wire into

the L2 screw terminal on the jumper bar assembly. Tighten

the set screw until the wire is securely fastened to the L2

screw terminal.

e. Secure the jumper bar cover to the jumper bar assembly

with the 2 screws removed in Step 6a above.

f. Once all of the wiring connections have been made, secure

the incoming power supply cable by tightening the cable

connector around the incoming power supply cable.

g. Refer to the instructions that came with the jumper bar

assembly for additional installation information.

h. Refer to Table 6 for the required wire size and required

overcurrent protection (fuse/circuit breaker) size.