i-1

Contents

Contents

1. Introduction.......................................................................................................................................1

1.1 Foreword ............................................................................................................................................1

1.2 Supplied documentation .....................................................................................................................1

1.3 Customer service................................................................................................................................2

1.4 Spare parts .........................................................................................................................................2

1.5 Declaration of conformity....................................................................................................................2

1.6 Unauthorized changes........................................................................................................................2

1.7 Allowed and non-allowed use.............................................................................................................2

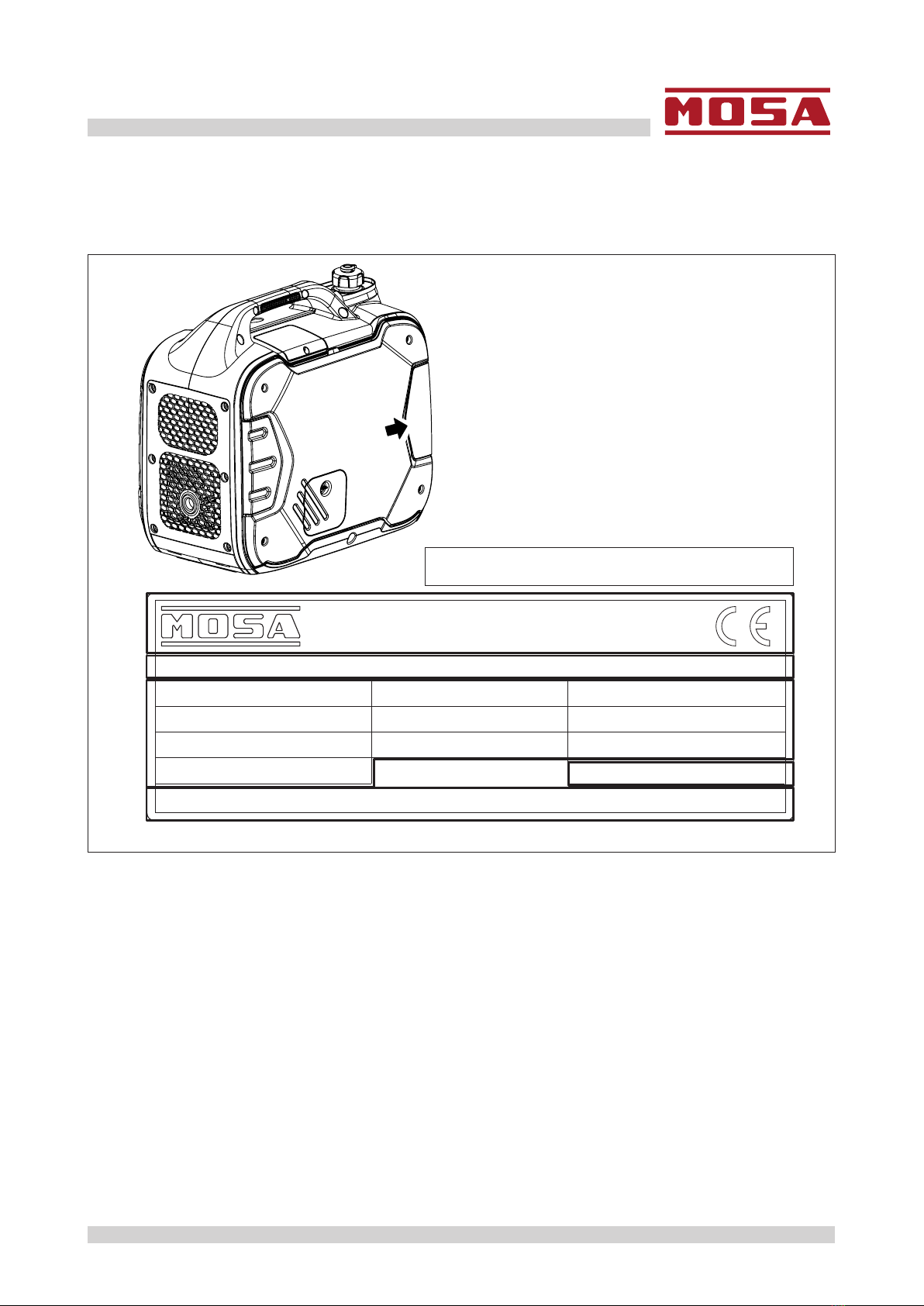

1.8 Identicationdata ...............................................................................................................................3

1.9 Sound power level ..............................................................................................................................4

2. Safety.................................................................................................................................................5

2.1 Safety information...............................................................................................................................5

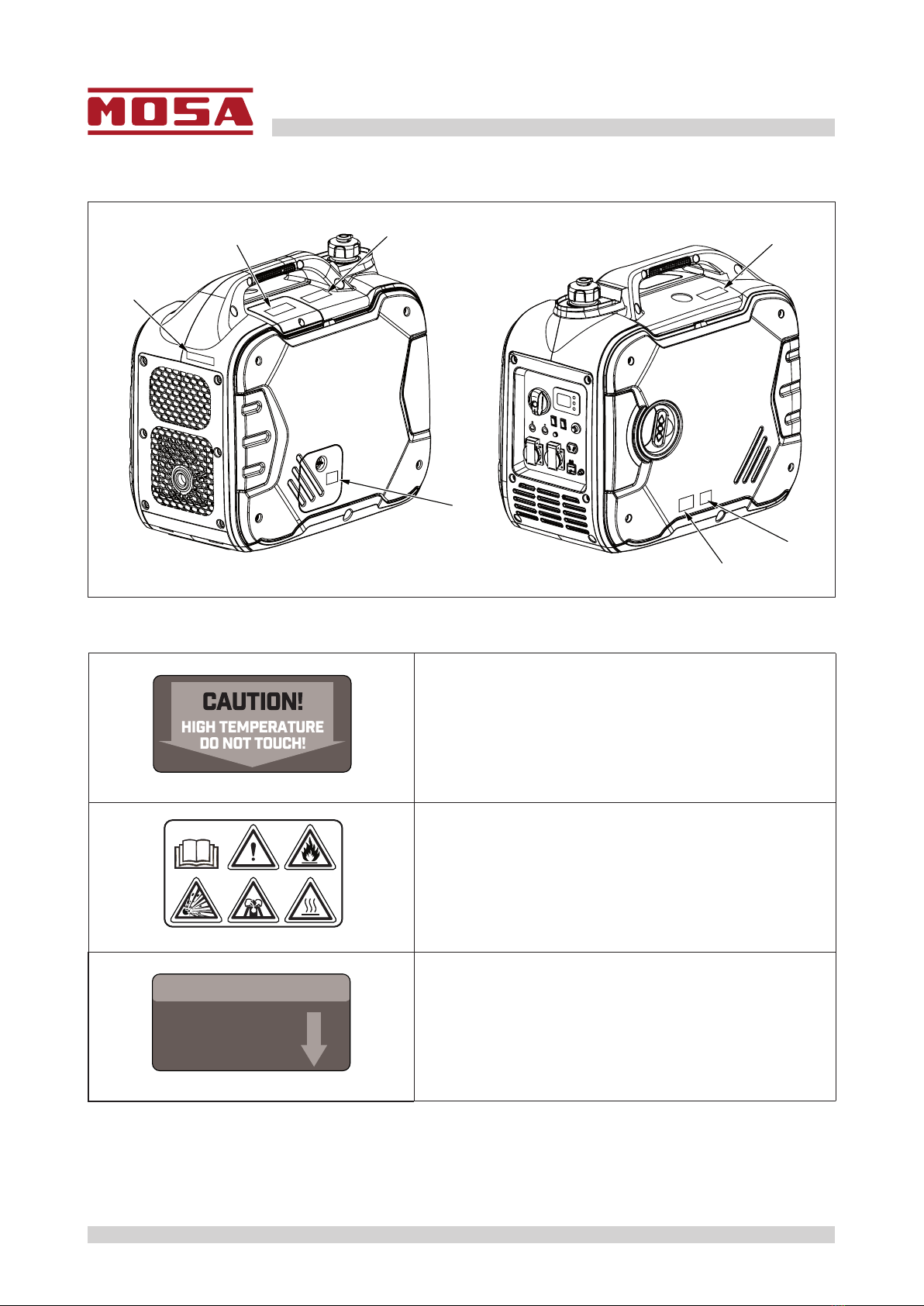

2.2 Positioning of safety decal and information........................................................................................6

2.2.1 Decal explanation ..................................................................................................................6

2.3 General precautions ...........................................................................................................................8

2.3.1 Personal protective equipment ..............................................................................................8

2.3.1 Check the work area..............................................................................................................8

2.4 Fire prevention....................................................................................................................................9

2.4.1 Fire due to fuel, oil .................................................................................................................9

2.4.2 Firescausedbyammablematerialbuild-up ........................................................................9

2.4.3 Fire caused by electrical wiring .............................................................................................9

2.4.4 Fire caused by piping ............................................................................................................9

2.5 Lifting and transport precautions ........................................................................................................9

2.5.1 Lifting and manual transport ..................................................................................................9

2.6 Precautions for positioning the machine.............................................................................................9

2.6.1 Positioning site precautions...................................................................................................9

2.6.2 Precautions for electric connections....................................................................................10

2.7 Precautions during operation............................................................................................................10

2.8 Precautions against noise ................................................................................................................10

2.9 Precautionsduringfuelandengineoillling .................................................................................... 11

2.10 Maintenance precautions ................................................................................................................. 11

2.11 Precautions for disposal of waste material .......................................................................................12

2.12 Disposal of the machine ...................................................................................................................12

3. Technical data.................................................................................................................................13

3.1 GE 3500 MI technical data ...............................................................................................................13

3.2 Electrical diagram .............................................................................................................................14

4. Description......................................................................................................................................15

4.1 Main components .............................................................................................................................15

4.2 Control panel components................................................................................................................16

4.2.1 Explanation of control panel components............................................................................17

5. Delivery, unpacking and installation ............................................................................................21

5.1 Delivery.............................................................................................................................................21

5.2 Unpacking.........................................................................................................................................21