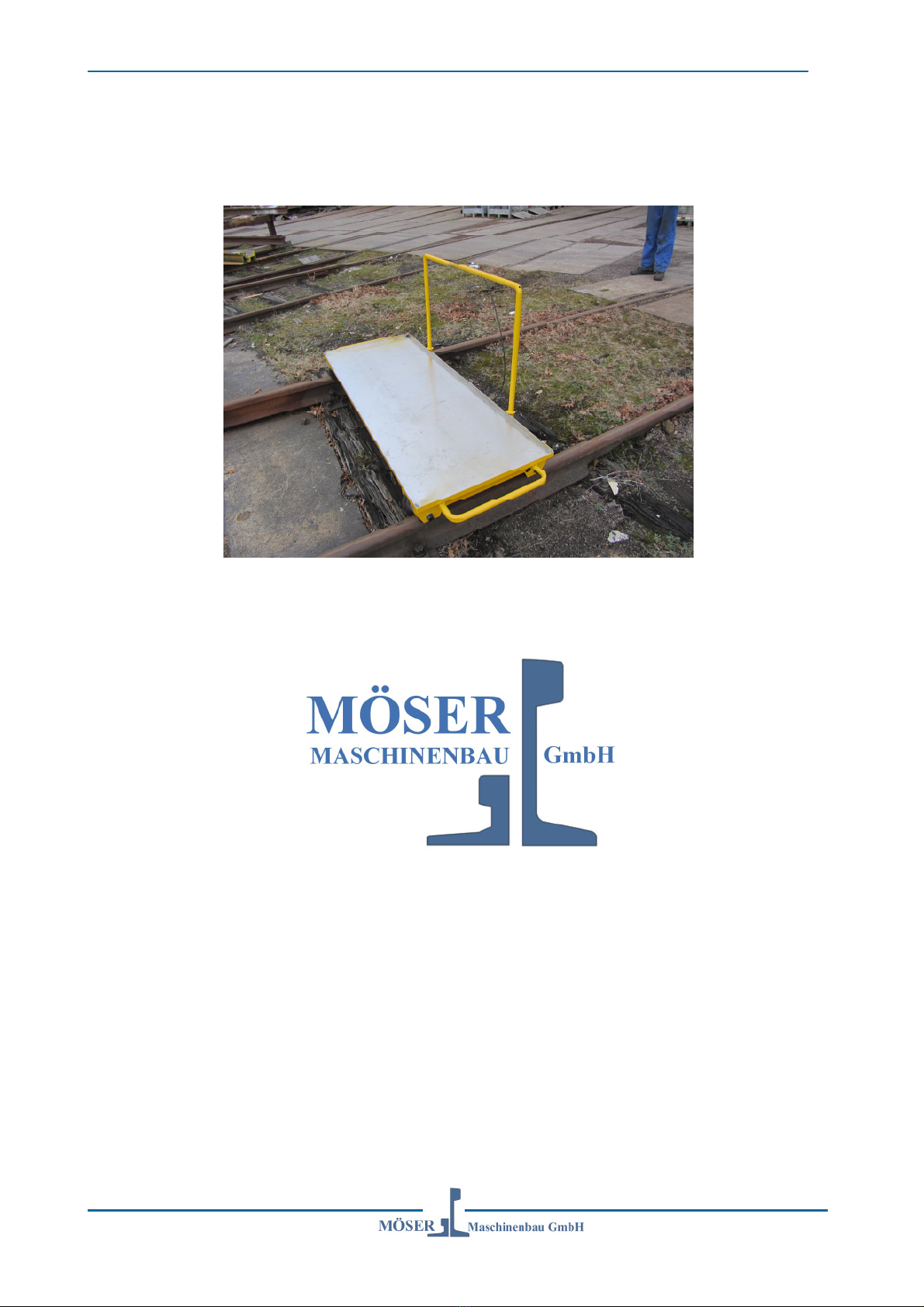

Operating instructions aluminium trolley Ro-V 282

2

contents

1. How to use this manual..............................................................................................3

2. Pleas note....................................................................................................................4

2.1 Foreword ...............................................................................................................4

2.2 Safety instructions .................................................................................................7

2.2.1 Use for intended purpose ...............................................................................7

2.2.2 Use of skilled personnel .................................................................................7

2.2.3 Working clothes..............................................................................................8

2.2.4 Operating safety instructions ..........................................................................8

2.2.5 Loads..............................................................................................................9

2.2.6 Entering and leaving the machine ..................................................................9

2.2.7 Safety notes in this manual ..........................................................................10

2.2.8 Preconditions for safety................................................................................11

2.2.9 Personnel .....................................................................................................11

2.2.10 Mechanical dangers .....................................................................................13

3. Description and explanation....................................................................................14

3.1 Technical specifications.......................................................................................14

3.2 General drawing ..................................................................................................15

3.2.1 Trolley in clearance profile German and Norwegian railway.........................16

3.3 Main frame/axle bridges ......................................................................................17

3.4 Rail wheels ..........................................................................................................18

3.4.1 Wheel profile ................................................................................................19

3.5 On track braking system......................................................................................20

3.5.1 Technical specifications................................................................................20

Maintenance and repair...................................................................................................22

3.6 General information .............................................................................................22

3.7 Regular checks and maintenance .......................................................................24

3.8 Self made repairs or attachments........................................................................26

4. Spare parts................................................................................................................27

5. Risk analysis.............................................................................................................29

6. Declaration of conformity ........................................................................................31

6.1 EG – Konformitätserklärung ................................................................................32