Neutronics H1301 User manual

Model H1301 Recovery and Recycling System

Installation, Operation and Maintenance Manual

Revision-L September, 2019

Page 2 of 105

Table of Contents page

I. Unpacking and Inspection 4

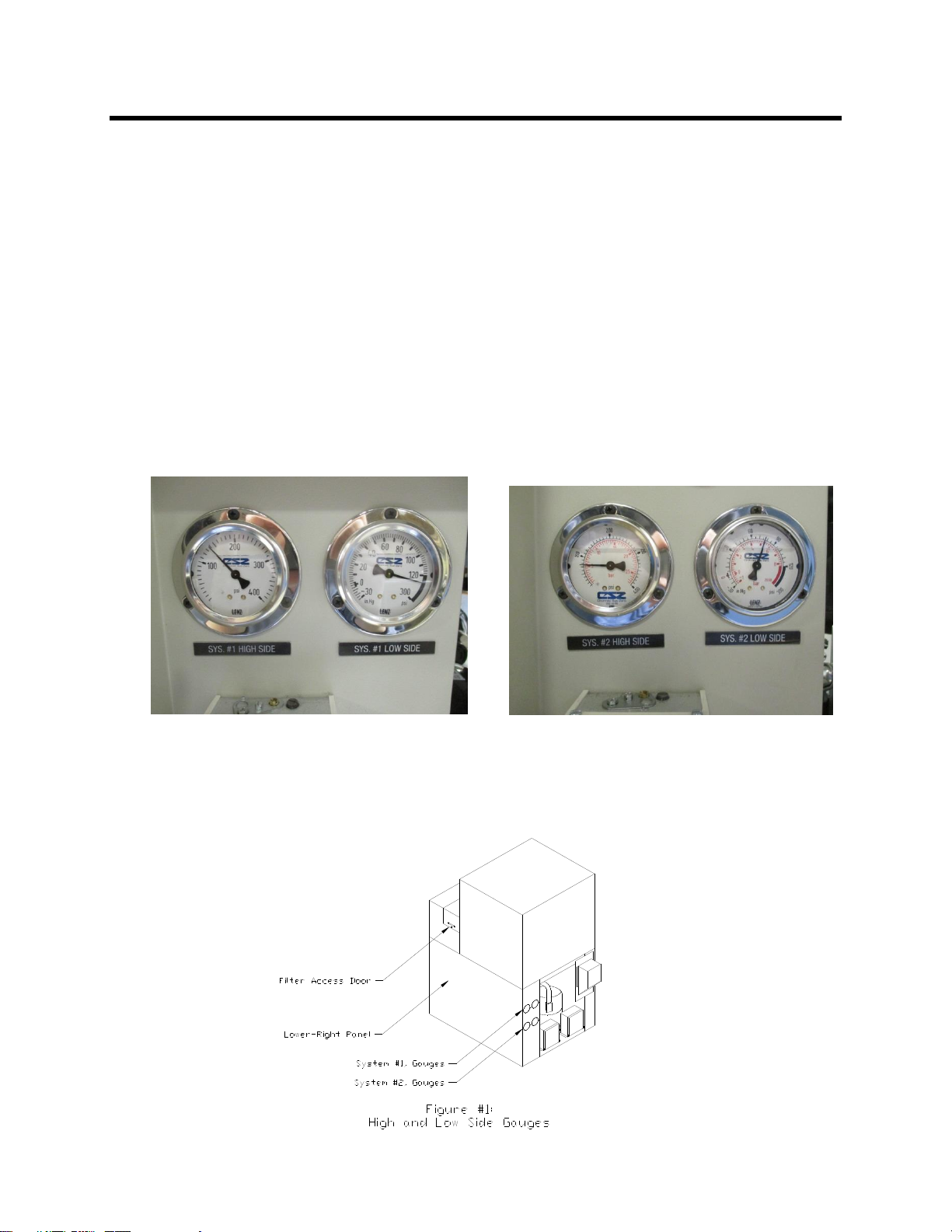

Figure #1: High and Low Side Gauges 4

II. System Warnings 5

A. General Safety Issues 5

B. Installation Warnings 5

C. Operation Warnings 6

D. Maintenance Warnings 7

III. General System Description 8

Figure #2: System Component Overview 8

IV. System Installation 9

Figure #3: Dimensional Reference 9

A. Machine Location 10

Figure #4: Port Locations 10

B. Pressure Relief Valve 11

C. Electrical Supply Requirements 12

D. Nitrogen Vent Port 13

E. Nitrogen Supply 14

F. Agent Receiver Storage Container Connections 15

G. Agent Source Container Connections 19

V. System Operation and Controls 22

A. Manual Overrides and System Control Description 22

Figure #5: Front Control Panel Detail 23

B. Initial System Start-Up Procedure 26

C. Inlet Pressure Switch Description and Adjustments 28

D. Automatic System Operation 32

E. Disconnecting the Source Container When it is not Empty 35

F. Receiving Container Replacement 36

G. System Shutdown 37

VI. System Operation Description and Component Review 38

A. PLC Status Indicators 38

B. The Nitrogen Vent Cycle 39

C. Inlet Recovery Review 40

D. Filtration Review 40

E. Nitrogen Separation Review 41

F. Pump Out Review 42

(Table of Contents Continues on Next Page)

Model H1301 Recovery and Recycling System

Installation, Operation and Maintenance Manual

Revision-L September, 2019

Page 3 of 105

Table of Contents (continued) page

VII. System Maintenance Procedures 43

A. Recommended Spare Parts Listing 43

B. Recommended Maintenance Schedule 43

Figure #7: Recommended Maintenance Schedule 43

C. Moisture Indicator Inspection 44

D. Particulate Filter Indicators 44

E. Cooling System Pressures 45

F. Vapor Compressor Oil Maintenance 46

Figure #8: Vapor Compressor Sight Glass Oil Level 46

Figure #9: Vapor Compressor Component Identification 48

G. Condenser Coil Cleaning 49

H. Moisture, Acid and Processed Particulate Filter Element Replacement 50

Figure #10: Exploded Filter Details 53

Figure #11: Filtration Component Identification 54

I. Inlet Particulate Filter Replacement 55

J. Heat Exchanger Evacuation 57

Figure #12: Processing Tank Component Details 58

K. Complete System Evacuation 59

Figure #13: Outlet Component Identification 63

L. System Leak Testing 65

M. Pressure Controller Calibration 66

Figure #14: 4-20mA Loop Component Locations 66

Figure #15: Pressure Controller Detail 67

Figure #16: Loop Power Supply Detail 70

Figure #17: Pressure Transmitter Testing 73

N. Process Temperature Controller Calibration 78

Figure #18: Process Temperature Components 78

Figure #19: Temperature Controller Detail 79

Figure #20: Temperature Controller and Probe 82

O. Vapor Compressor Oil Renewal 85

P. Cooling System Controller Setting 87

Figure #21: Cooling System Controller Detail 87

Q. Inlet Vacuum Switch Calibration 91

Figure #22: Vacuum Switch Test Plumbing 91

Figure #23: Inlet Vacuum Switch Detail 92

R. Outlet Section Maintenance 93

VIII. System Troubleshooting Guide 94

A. Error Code Description 94

B. Machine Will Not Operate 96

C. Cooling System Will Not Operate 96

D. Cooling System is Not Cooling Properly 96

E. System Ready Lamp Will Not Illuminate 96

F. Machine Will Not Perform Inlet Processing 97

G. Machine Will Not Evacuate Source 98

H. Machine Will Not Vent 98

I. Machine Will Not Pump Out 98

J. Solenoid Valve Troubleshooting 99

K. Liquid Pump Troubleshooting 100

L. Liquid Level Switch Troubleshooting 102

M. Vapor Compressor Troubleshooting 103

IX. System Specifications 104

X. System Warranty 105

Model H1301 Recovery and Recycling System

Installation, Operation and Maintenance Manual

Revision-L September, 2019

Page 4 of 105

I. Unpacking and Inspection

A. Upon receipt of the system, visually inspect the shipping carton for signs of

damage or mishandling. Immediately contact the carrier for an inspection if the

shipping carton is damaged or evidence of mishandling exists.

B. Carefully remove the outer crating materials. Care must be taken during

unpacking to avoid enclosure damage or scratching.

C. Inspect the system for dents, scratches, or other evidence of mishandling during

shipment. Request an immediate inspection from the carrier if damage is evident.

D. Inventory the contents of the shipping carton against the packing list provided

with the shipping documents.

E. Observe the pressure indications of the Refrigeration Section: System #1- High

and Low side and System #2 –High and Low side pressure gauges located at

the lower-rear panel of the machine: refer to figure #1 below. Pressure

indications below 130 psi for system #1 and below 65 psi for system #2 may

indicate a break in the plumbing: Contact the factory for further assistance.

F. Open the Filter Access Door located at the top-right corner of the Control Panel

Black Hood. Using an inspection light source visually verify the integrity of the

internal tubing contained under the Hood. Close the Filter Access Door.

Model H1301 Recovery and Recycling System

Installation, Operation and Maintenance Manual

Revision-L September, 2019

Page 5 of 105

II. System Warnings

The following lists warnings concerning the installation, operation, and maintenance of the

system as well as general safety issues. The warnings listed here are both specific and

generalized and may or may not be repeated throughout the manual

A. General Safety Issues

KEEP AWAY FROM LIVE ELECTRICAL CIRCUITS. Operating personnel should

observe all safety precautions at all times. Do not replace components or make

adjustments inside the equipment with the high voltage energized to the system unless

directed to do so in the maintenance sections of this manual. Dangerous potentials exist

internal to the system and under certain conditions may exist even with the system power

switch in the off position.

DO NOT SERVICE OR ADJUST THE SYSTEM ALONE. All maintenance or

system adjustments should be accomplished in the presence of someone capable of

rendering aid in the unlikely event of injury.

ONLY PERMIT FULLY TRAINED PERSONEL TO OPERATE THE SYSTEM.

COMPLETELY READ AND UNDERSTAND THIS MANUAL BEFORE

ATTEMPTING INSTALLATION, OPERATION, OR MAINTENANCE TO THE

EQUIPMENT.

ALWAYS WEAR SAFETY GLASSES when operating the equipment or working with

the Agent containers.

B. Installation Warnings

DO NOT INSTALL THE SYSTEM IN AN OUTDOOR ENVIRONMENT. The

system is designed for indoor locations with ambient temperature from 70 to 80 degrees F

(21.1to 26.7C).

DO NOT LOCATE THE SYSTEM NEAR DRIPPING, SPRAYING, OR

STANDING MOISTURE OR WATER. The system enclosure IS NOT NEMA rated.

Contact with moisture and water may result in electrical short circuits which may cause

health and system hazards.

ALWAYS LOCATE THE SYSTEM ON AN EVEN AND LEVEL SURFACE, use

wheel chocks to insure the machine will not roll if accidentally pushed, or roll from

operational vibration.

ALWAYS MAINTAIN A SERVICE AREA OF 3-FEET AROUND ALL SIDES OF

THE MACHINE to provide adequate ventilation of the refrigeration section.

ALWAYS ATTEMPT TO LOCATE THE SYSTEM IN AN AREA THAT IS

COOL, DRY, AND AWAY FROM DIRECT SUNLIGHT.

DO NOT LOCATE THE EQUIPMENT IN OR NEAR THE VICINITY OF FLAMMABLE

MATERIALS OR VAPORS.

DO NOT CONNECT THE EQUIPMENT TO ANY POWER SOURCE OTHER THAN

SPECIFIED BY THE INSTALLATION PROCEDURES OF THIS MANUAL. FOLLOW

LOCAL AND NATIONAL SAFETY CODES WHEN INSTALLING THE EQUIPMENT.

ALWAYS ATTEMPT TO MAINTAIN A MINIMUM 3/16” INSIDE DIAMETER

PLUMBING CONNECTIONS TO THE PORTS OF THE MACHINE WITH A MINIMUM

OF BENDS, LOOPS, LOW SPOTS, OR SAGS.

Table of contents