PRODUCT INFORMATION

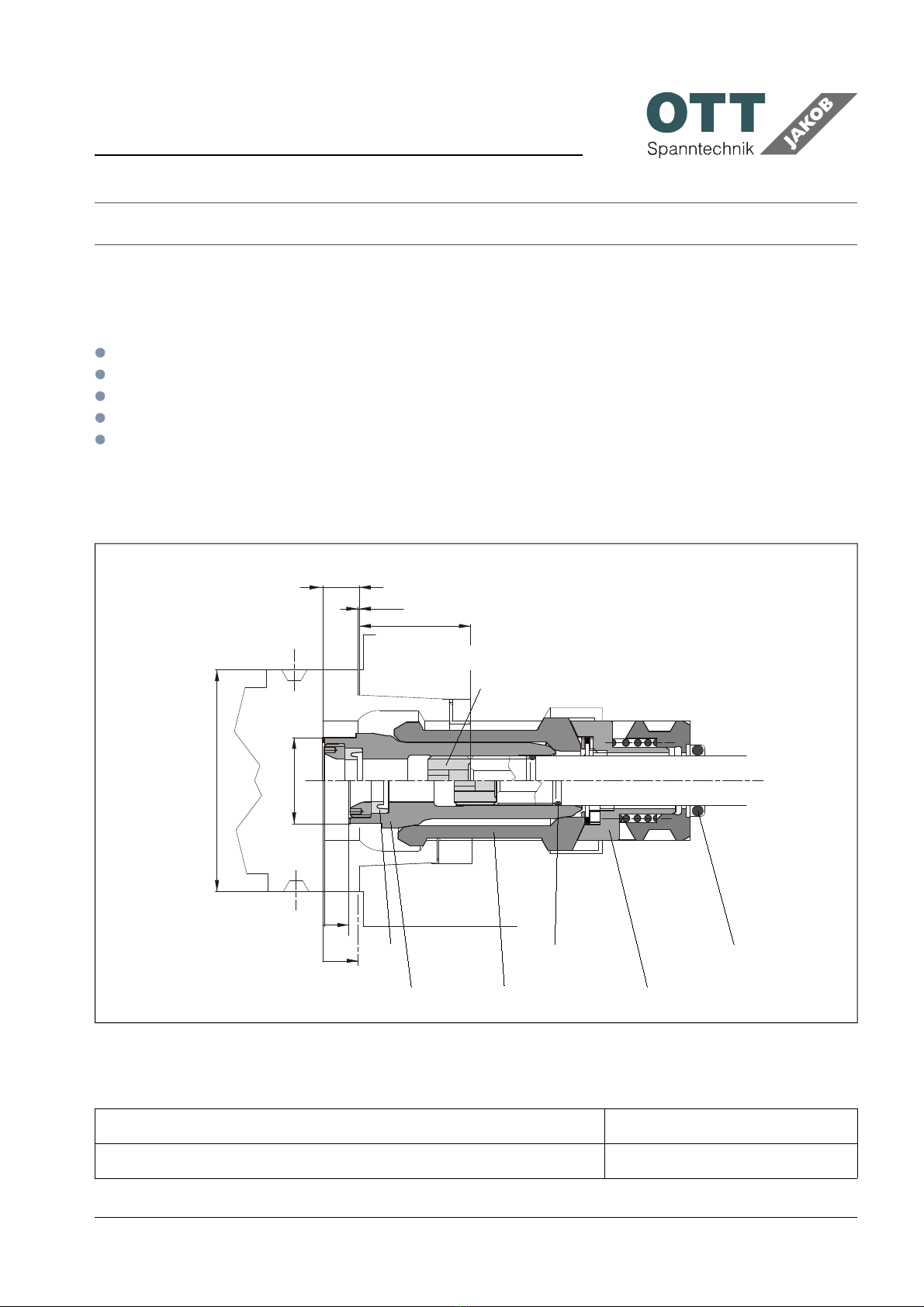

HSK A63-D

TABLE OF CONTENTS

1 PRODUCT DESCRIPTION..........................................................................................................3

1.1 FEATURES.................................................................................................................................3

1.2 DIMENSIONS.............................................................................................................................3

1.3 ORDER NUMBER.......................................................................................................................3

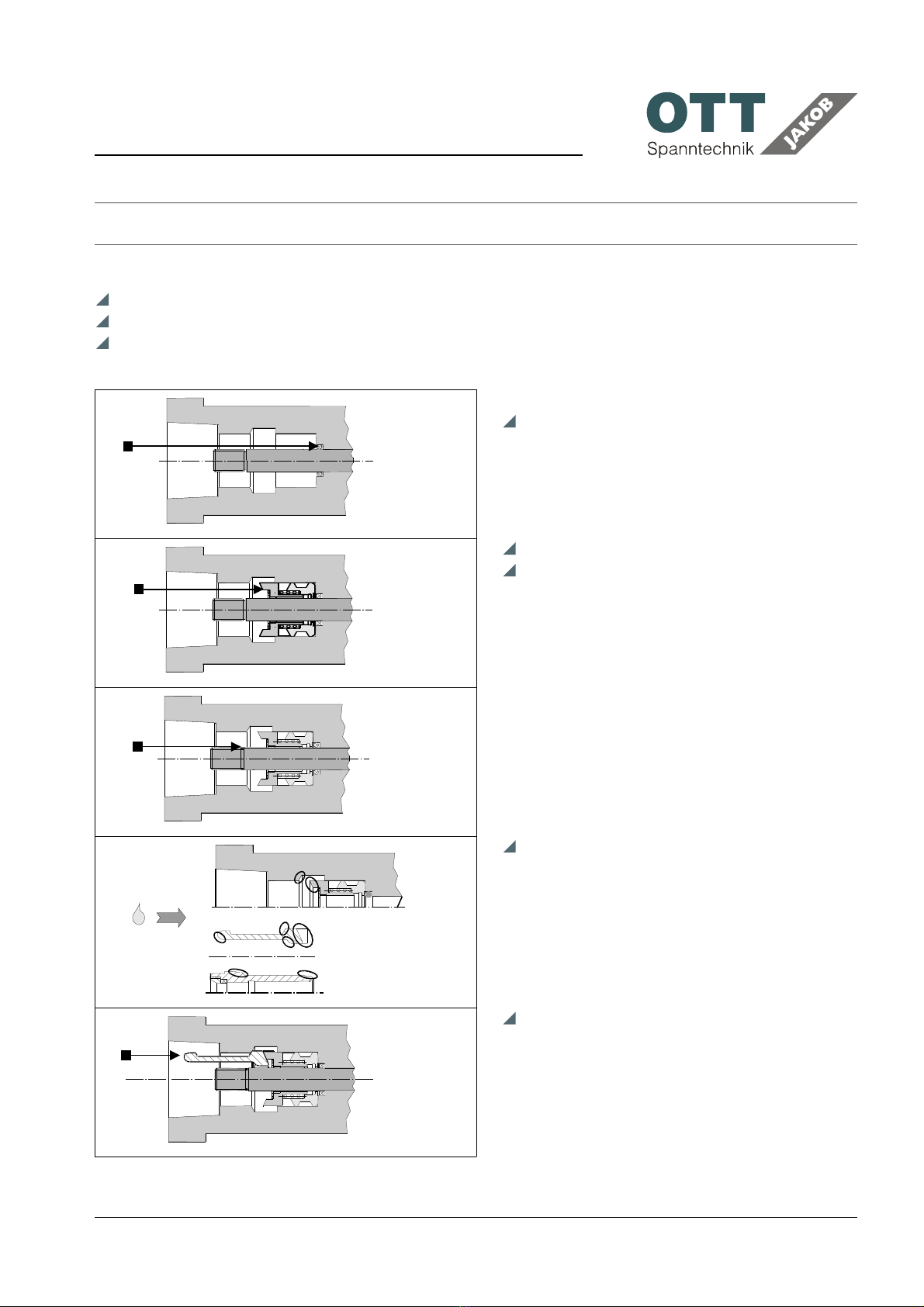

2 ASSEMBLY.................................................................................................................................4

3 OPERATION...............................................................................................................................6

3.1 TOOL INSERTING......................................................................................................................6

3.2 OPERATING CONDITIONS........................................................................................................7

3.3 INTERN COOLING SUPPLY.......................................................................................................7

3.4 COOLANT...................................................................................................................................8

3.5 GENERAL...................................................................................................................................8

4 MAINTENANCE.........................................................................................................................9

4.1 MAINTENANCE INTERVALS.....................................................................................................9

4.2 REGREASE CLAMPING UNIT..................................................................................................10

4.3 E CHANGE OF THE LIP SEAL................................................................................................11

4.4 BREAK OF A GRIPPER SEGMENT..........................................................................................11

4.5 DISASSEMBLE CLAMPING UNIT HSK...................................................................................12

4.6 WEARING PART LIST..............................................................................................................12

4.7 TROUBLE SHOOTING HSK......................................................................................................13

9560018926V00_PE_2018-09

Subject to modification due to technical advance! // 2