SSEMBLY OF BOOM

FigUI'e 1

>

Insert one end of the 48" center boom splice (Part 16 ) into one

end of the boom section (Part 17) marked #1 in BL CK. lign the holes

and secure with screws (Part 25)/ lockwashers (Part 26) and nuts (Part

27). Insert opposite end of splice into the remaining center section

boom marked #J in BL CK (Part 17), and secure with hardware (Parts 25,

6, 7).

>

The remaining boom sections (Part 17), can now be attached to

the center section at either end. Using the smaller splices, align

the holes and secure with hardware (Parts J6, 25, 26, 27). Press

caplugs (Part 20) on each end of boom.

<

>

Check that all bc,lts are tight, and have' lock•.•.•ashers in place.

SSEMBLY NO PL CEMENT OF M STPL TE

Figure 2

>

Place the mastplate (Part 18) between the joint at the center of

the boom. Place four #47 clamping blocks (Part 19) between the boom

and the mastplate and secure with the four 2

0

U-bolts (Part 8).

Secure the U-bolts with lockwashers and nuts (Parts 10/ 11).

SSEMBLY OF ORIVEN ELEMENT

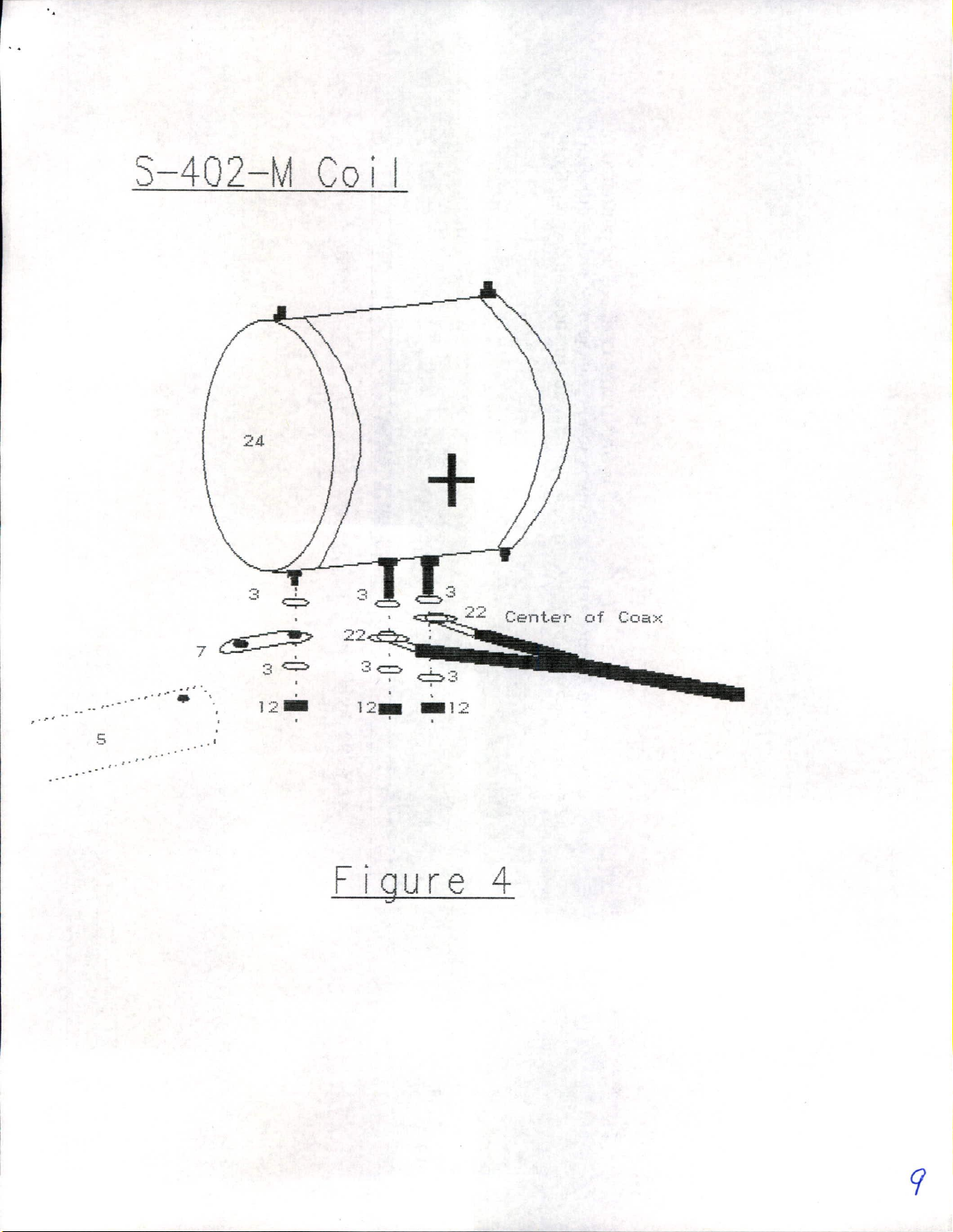

(Figure 3, 4, 5)

>

Loosely install 8 plastic insulators (Part 2) on the rectangle

support plate (Part J) with lockwashers and screws (Parts 3, 4).

Place plastic caps (Part 21) on the inboard end of the element

sections (Part 5). Place one element section into the

"'ID

on the

insulatc<i's(Part 2) so t.hat.the scre•.•.•hc/le cm the outbc,ard end is

fac ing OOWN ..

<>

Insert. screw (Part 6) through lockwasher (part 3), the small

hole on one end of t.he coil bracket. (Part 7) through t.he element. (Part.

5) and int.eot.he iilSU1atcn-'(Part 2). 1nser t scre'....(Pal't.6) tt-,",'ought.he

lockwasher (Part. 3), element (Part 7) and into the insulateor (Part 2).

DO NOT OVER TIGHTEN SCREWS INTO INSUL TOR BLOCKS ....

>

Place the eot.herelemeilt sectieon (Part 5) ceoleorcoded red over

the opposite side iilsulators (Part. 2), iilsert screw (part 6) through

leockwasher (Part 3), threough the corresponding hole Con the coil

bracket (Part 7), the element (Part 5) and int.o t.he insulator (Part.

2)

<

>

Iilsert screw (Part 6) threough lockwasher (Part 3), elemeilt (Part

5) and iiltO the insulator" (Pal't 2). Tighten all SC1'ews in the element

support.s, BUT do not eover tighteil screws. Tighten enough to set

leock',l,/ashel's.

2>