i:||ee

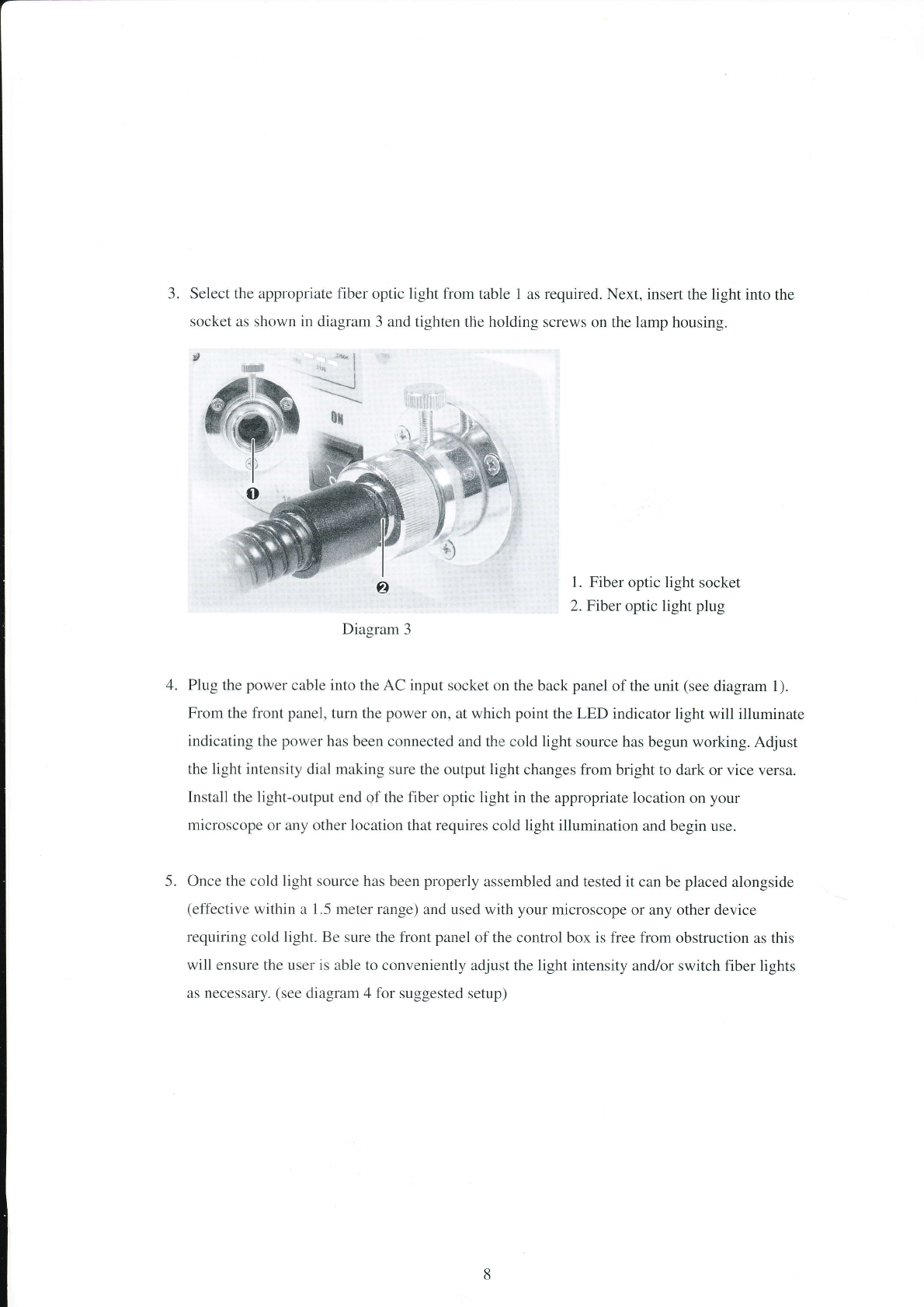

3. Select the appropriate fiber optic light from table 1 as required. Next, insert the light into the

socket as shown in diagram 3 and tighten the holding screws on the lamp housing.

',t* '* | -:

x{

1. Fiber optic light socket

2. Fiber optic light plug

Diagram 3

Plug the power cable into the AC input socket on the back panel of the unit (see diagram 1).

From the front panel, turn the power on, at which point the LED indicator light will illuminate

indicating the power has been connected and the cold light source has begun working. Adjust

the light intensity dial making sure the outpllt light changes from bright to dark or vice versa.

Install the light-output end of the fiber optic light in the appropriate location on your

microscope or any other location that requires cold light illumination and begin use.

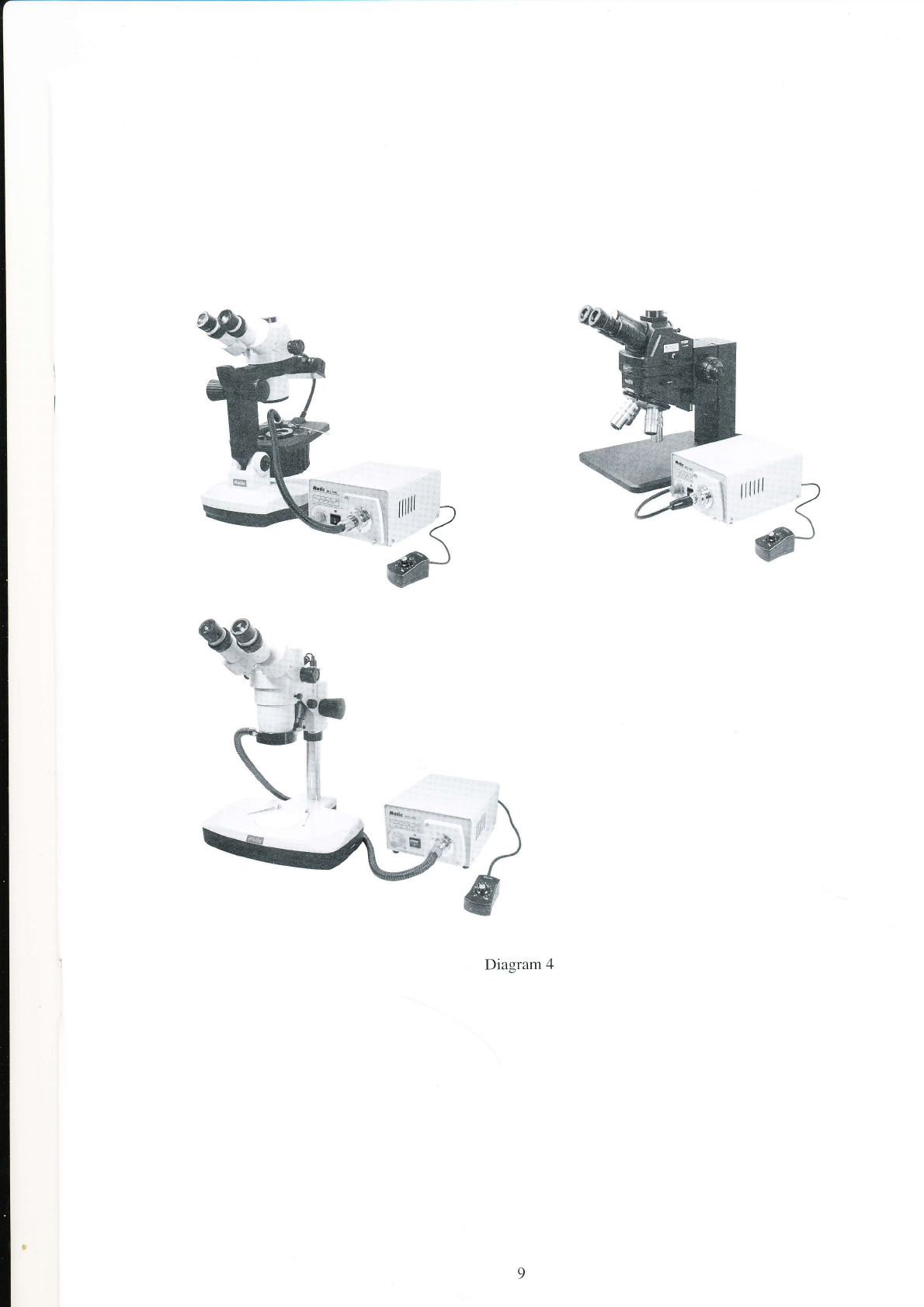

Once the cold light source has been properly assembled and tested it can be placed alongside

(effective within a 1.5 meter range) and used with your microscope or any other device

requiring cold light. Be sure the front panel of the control box is free from obstruction as this

will ensure the user is able to conveniently adjust the light intensity and/or switch fiber lights

as necessary. (see diagram 4 for suggested setup)

ôx

4.

5.