4

v1.0.0

EvoDrive+ maintenance manual

GB

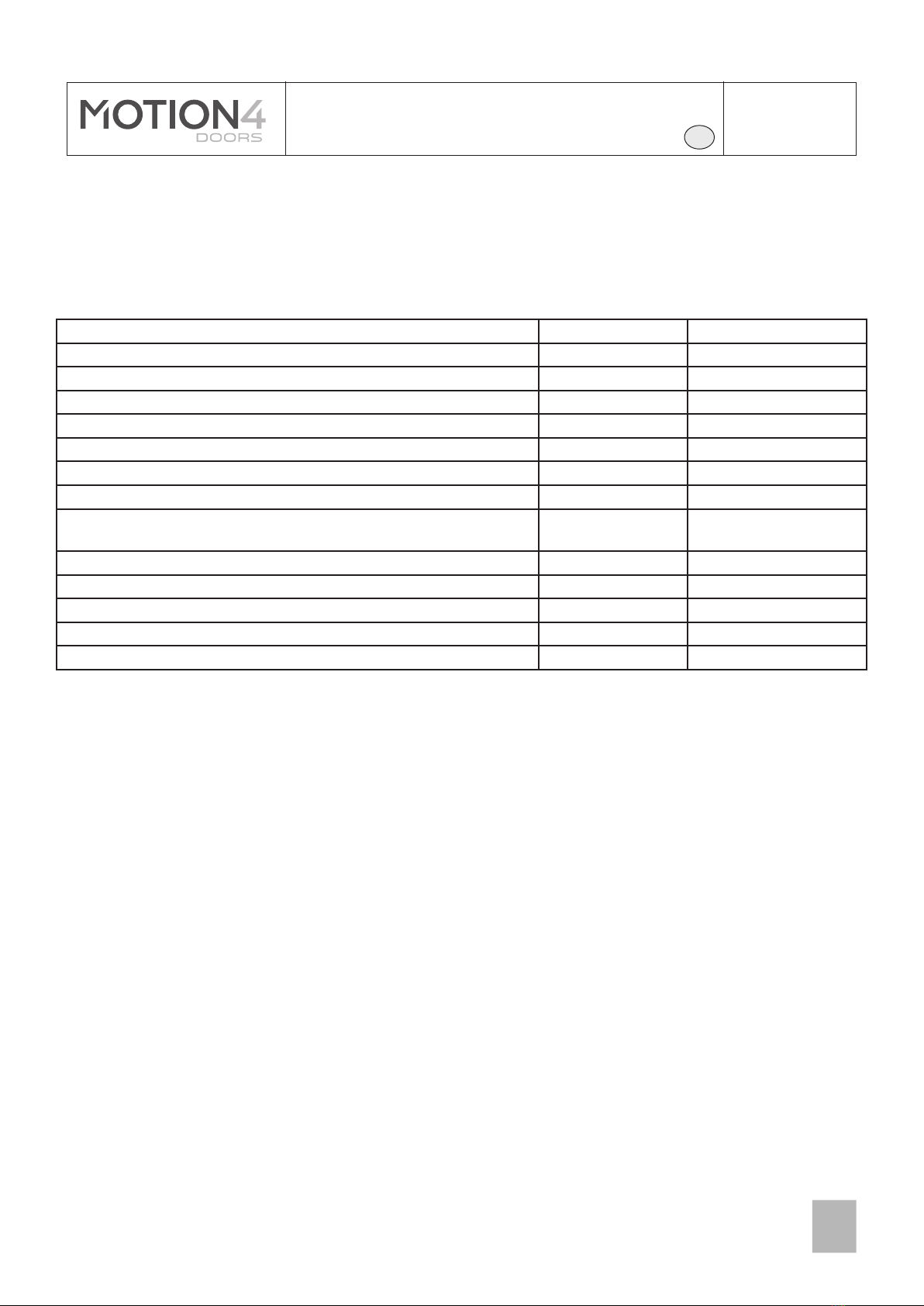

4. BASIC TROUBLESHOOTING

Situation/Problem Solution

Obstruction detection

during the closing cycle

Obstruction detection

during the opening cycle

Leaf is moving too slow

Leaf does not move

Leaf hits the users

Self-adjustment never ends

Door vibrates at the end of

the opening movement

Door knocks at the end of

the opening movement

Door vibrates at the end of

the closing movement

Door knocks at the end of

the closing movement

- Check and remove obstructions in the opening travelling area.

- Check that leaf can be moved manually and smoothly.

- Verify that the nal adjustment has been made, see p. 19 of EvoDrive+

installation manual.

- In the case of having sensors installed, verify that the sensors are adjusted so

that the door is not detected by them.

- Check and remove obstructions in the opening travelling area.

- Check that leaf can be moved manually and smoothly.

- Verify that the nal adjustment has been made, see p. 19 of EvoDrive+

installation manual.

- Check if the operator is in Low Energy.

- Check that no item is generating excessively friction.

- Verify that the nal adjustment has been made, see p. 19 of EvoDrive+

installation manual.

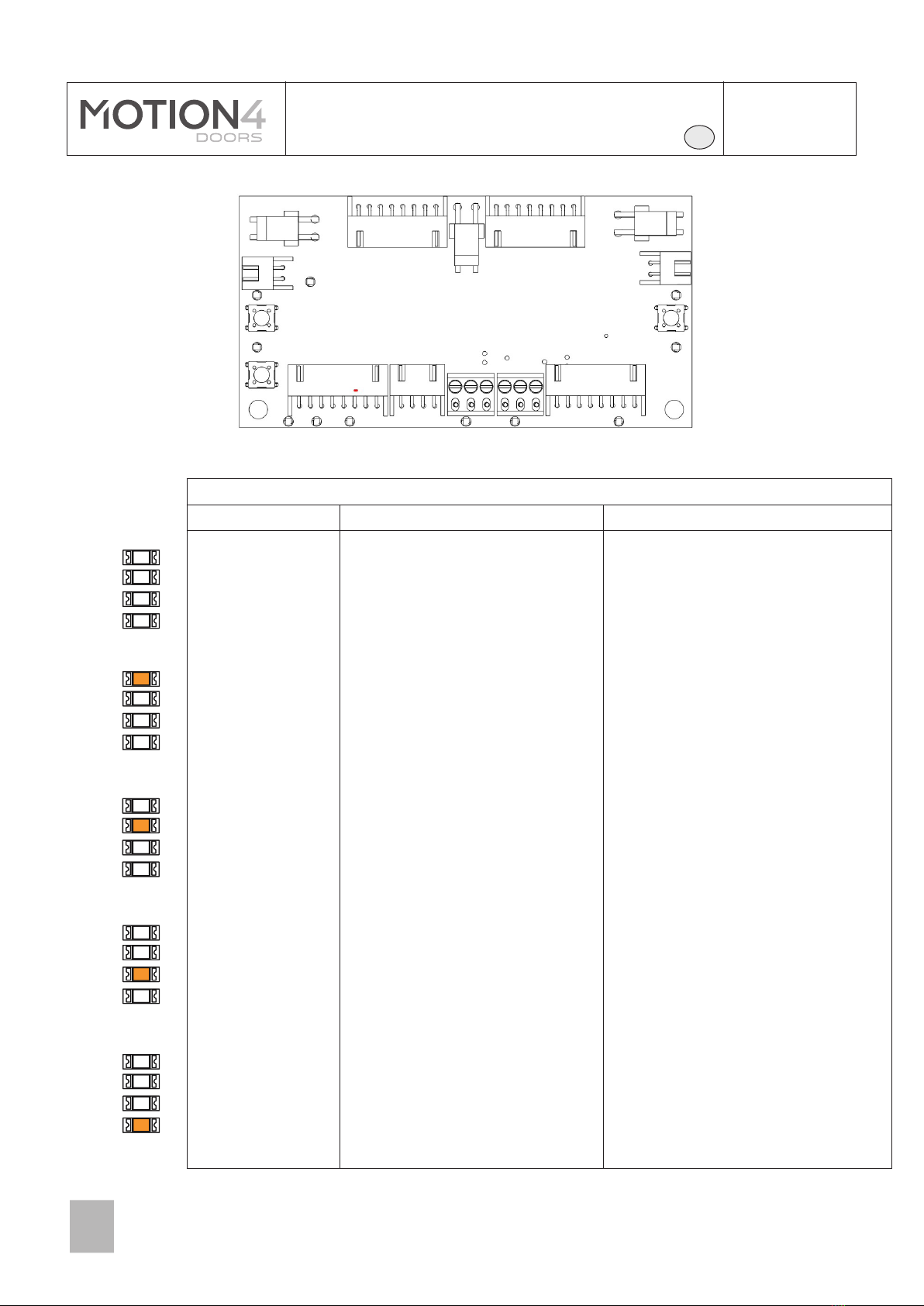

- Verify that I/O Accessories is switched ON.

- Verify that the operator is not in open mode.

- Verify that the sensors / accessories have been connected correctly.

- Verify that the nal adjustment has been made, see p. 19 of EvoDrive+

installation manual.

- Verify that all the sensor has been correctly adjusted.

- Check that the weight of the leaf is below 80 kg (max. admitted).

- Verify that the motor is fully covered with magnets in all of its lenght, from clo-

sing to opening.

- Verify that the nal adjustment has been made, see p. 19 of EvoDrive+

installation manual.

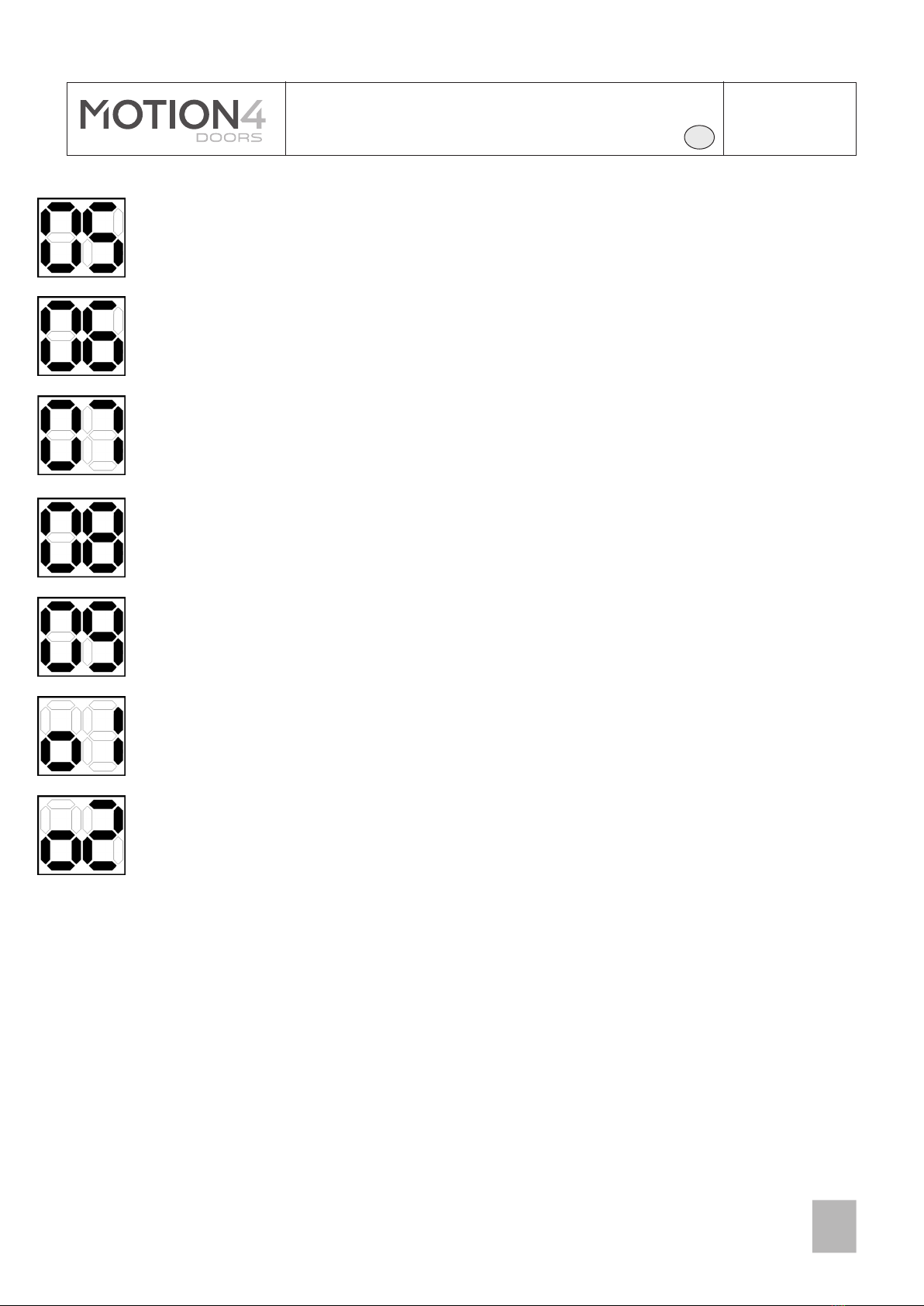

- Adjust the parameter 11 and 12 of the display decreasing their value.

- Adjust the parameter 11 and 12 of the display increasing their value.

- Adjust the parameter 08 and 09 of the display decreasing their value.

- Adjust the parameter 08 and 09 of the display increasing their value.