© Motor City Wash Works, Inc. 48285 Frank, Wixom Michigan 48393 U.S.A. Phone: 248.313.0272 ▪ Fax: 248. 313.0271

8MANLWRPCROVR01 09-16-20 www.motorcitywashworks.com 1

CROSS-OVER™ INSTALLATION MANUAL

Part # WRAPCHYD[ . . . . . ]03

WRAPCELE[ . . . . . ]03

FOR COTTON CLOTH™, STAR FOAM or C-CHANNEL FOAM BRUSHES

TABLE OF CONTENTS

Equipment Utilities Page: 1

Equipment Specifications Page: 1

Suggested Tools and Installation Materials Page: 2

Installation Instructions Page: 2

Electrical Installation Page: 12

Pneumatic Installation Page: 17

Optional Retract Air Panel Installation Page: 18

Optional Mirror Bump Air Panel Installation Page: 20

Foamer Installation Page: 22

Water Feed Installation Page: 23

Hydraulic Installation Page: 24

Start-Up Procedures Page: 25

Operation Page: 28

License Plate Adjustment Page: 33

Maintenance Page: 40

Troubleshooting………………………………………………………………………………………………………..Page: 43

Exploded Views………………………………………………………………………………………………………..Page: 47

Warranty………………………………………………………………………………………………………………..Page: 61

Equipment Utilities

Equipment Specifications and Features

Convenient 115VAC Single Phase Supply Minimizes Installation Cost

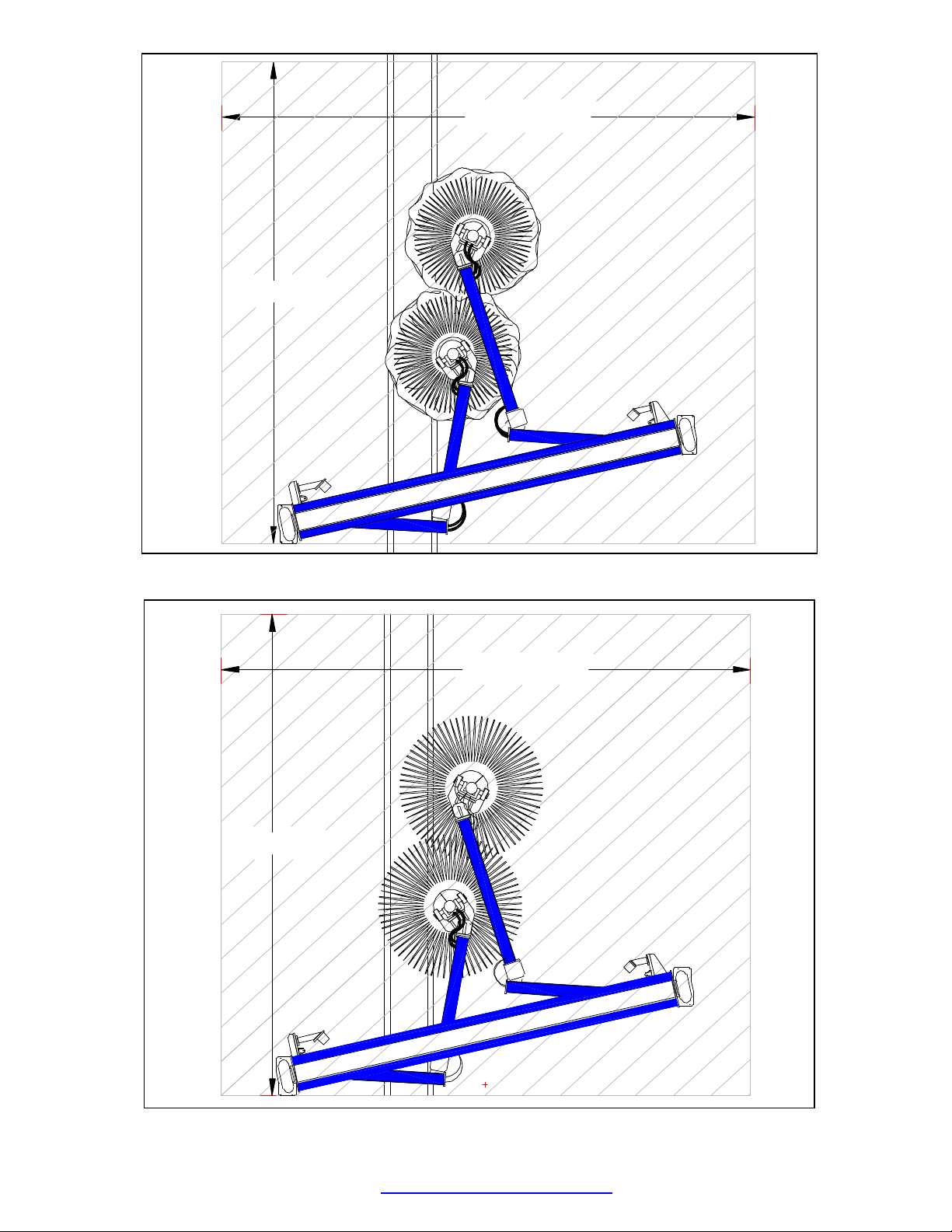

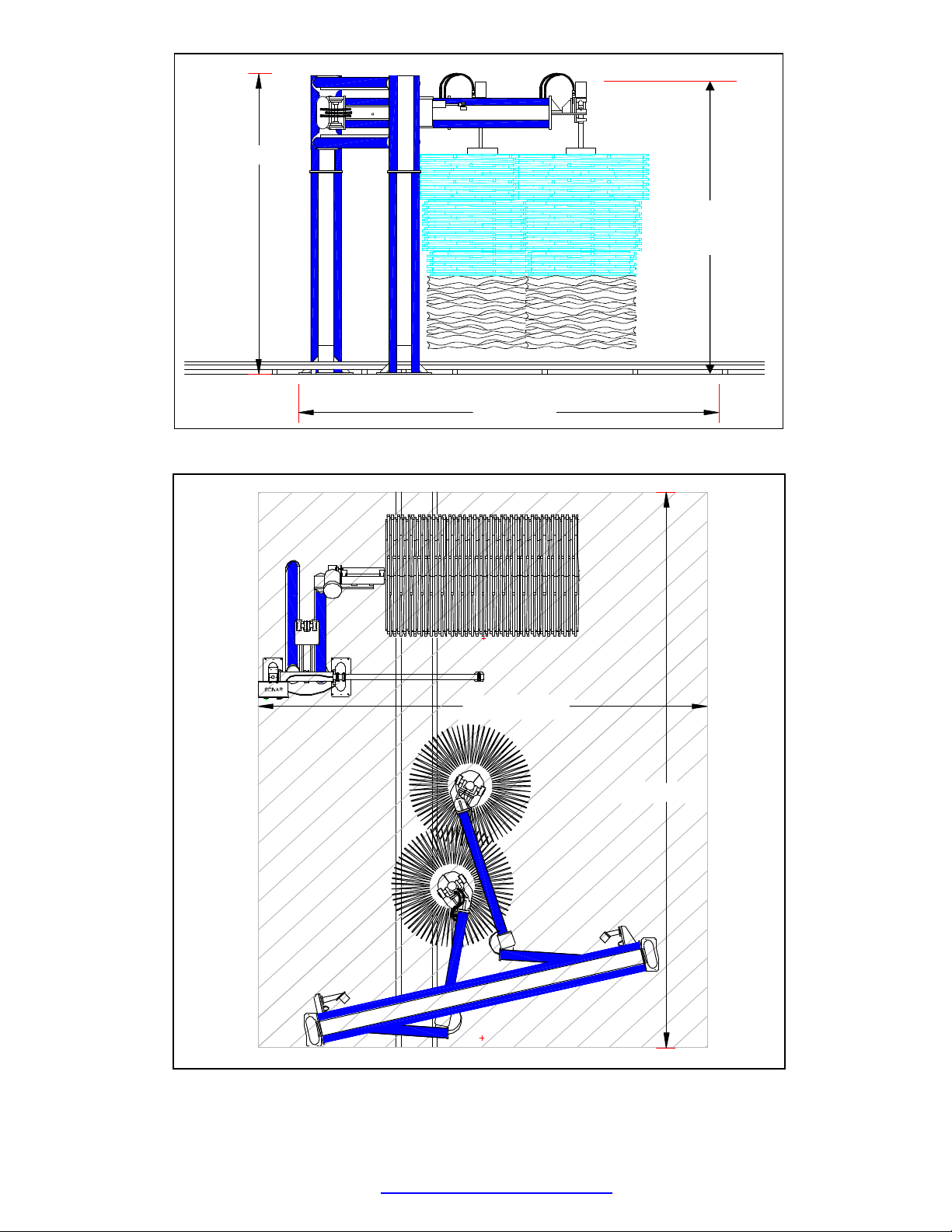

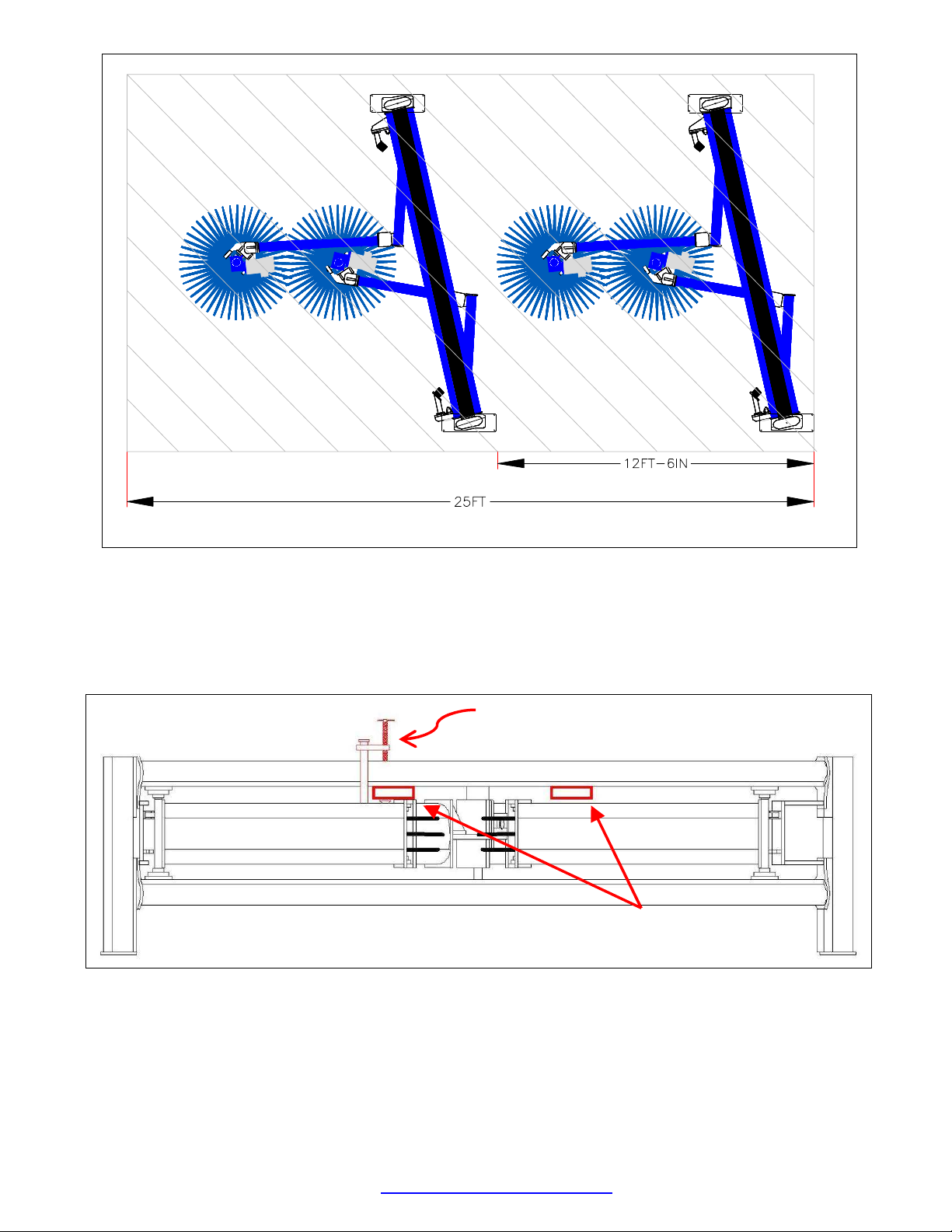

Compact Design: Utilizes only 14’-0” of Tunnel Space

Only 10’-00” Overall Height

Vehicle Clearance of More than 91”

Supplied Standard with MCWW Foam Streamers™ for Added Lubrication and Cleaning

Great Cleaning up to 180 CPH

Aluminum Structure with Color Skinz™ Snap-On UHMW Colored Covers… Great Appeal!

Electric or Hydraulic Drive Available

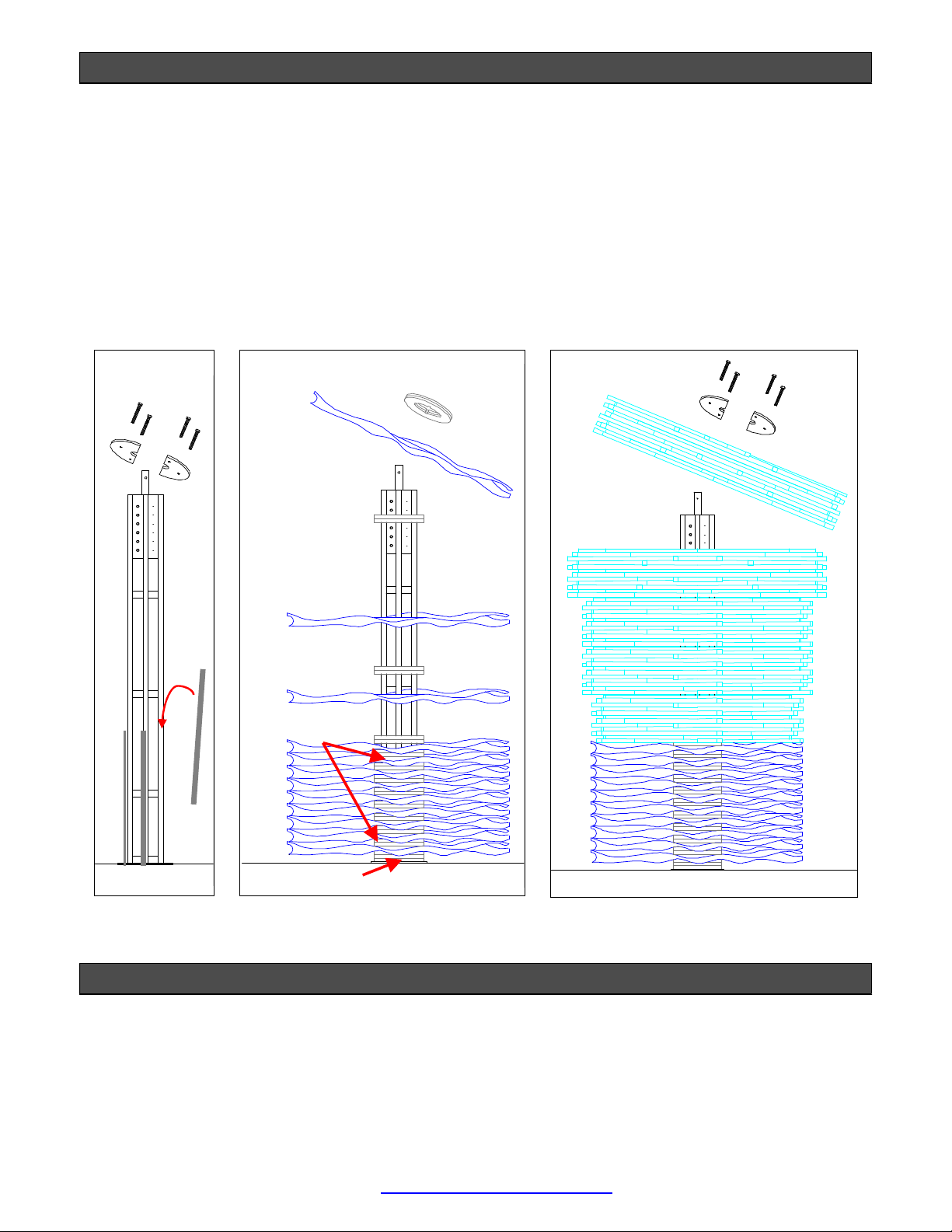

Choice of Cleaning Media between Cotton Cloth™, C-Channel and Star Foam

HYDRAULIC DRIVE

WRAPCHYD[ . . . . . ]03

ELECTRIC DRIVE

WRAPCELE[ . . . . . ]03

ELECTRICAL 120 VAC, 1 PH, 12 W VALVE UL® CERTIFIED

POWER: 120 VAC, 1 PH, 12 W VALVE UL® CERTIFIED

MOTORS: 3 HP (2 X 1.5 HP)

13.2-6 AMP @ 208-460 VAC, 3 PH

UL® RECOGNIZED, CSA CERTIFIED, CE MARK, IEC IP 55

HYDRAULIC 6 GPM @ 1000 PSI N/A

PNEUMATICS

2 SCFM @ 100 PSI

(INCLUDING OPTIONAL RETRACT PANEL)

2 SCFM @ 100 PSI

(INCLUDING OPTIONAL RETRACT PANEL)

WATER RECLAIMED OR FRESH:

4 GPM @ 40 PSI

RECLAIMED OR FRESH:

4 GPM @ 40 PSI