© Motor City Wash Works, Inc. 48285 Frank, Wixom Michigan 48393 U.S.A. Phone: 248.313.0272 ▪ Fax: 248. 313.0271

REVISION 2.3 10-07-20 www.motorcitywashworks.com 1

MOTOR CITY ROCKERZ INSTALLATION MANUAL

Part # ROCKRHYD[ . . . . . . . ]

ROCKRELE[ . . . . . . . ]

(ALL COLORS)

TABLE OF CONTENTS

Equipment Specifications Page: 1

Equipment Features Page: 1

Suggested Tools and Installation Materials Page: 1

Installation Instructions Page: 2

Electrical Installations Page: 7

Hydraulic Installations Page: 8

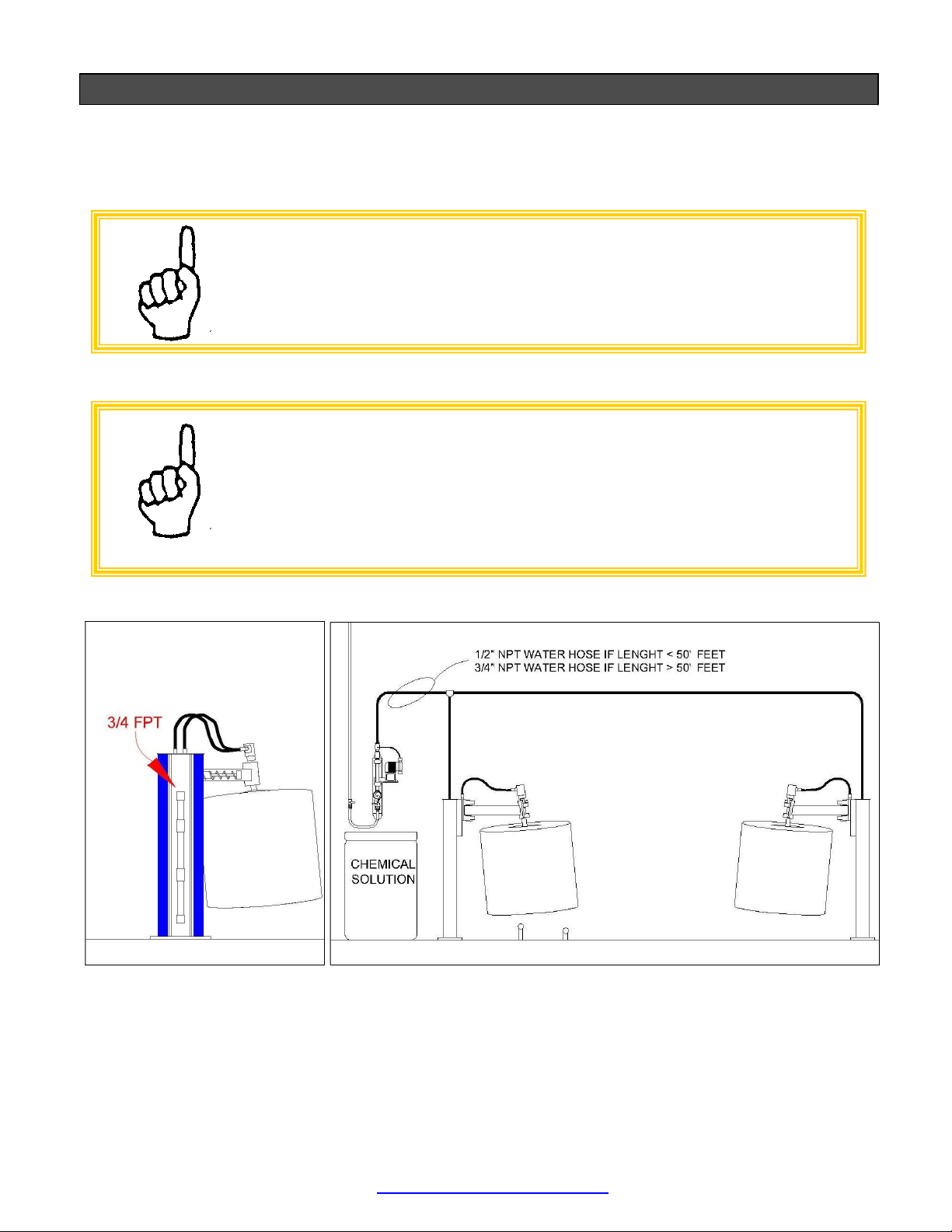

Plumbing Installations Page: 9

Start-Up Procedures Page: 10

Maintenance Page: 10

Troubleshooting………………………………………………………………………………………………………..Page: 13

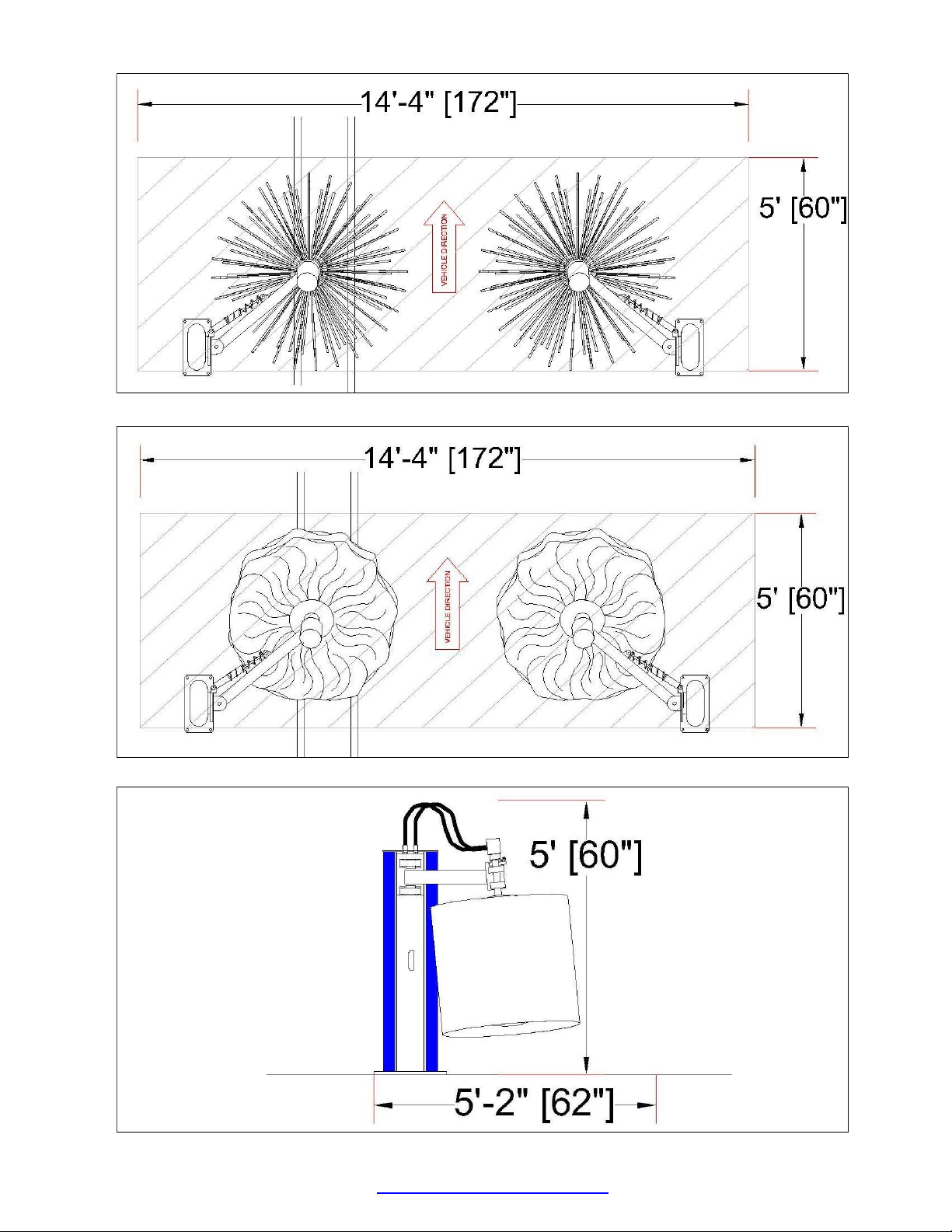

Equipment Specifications

Equipment Features

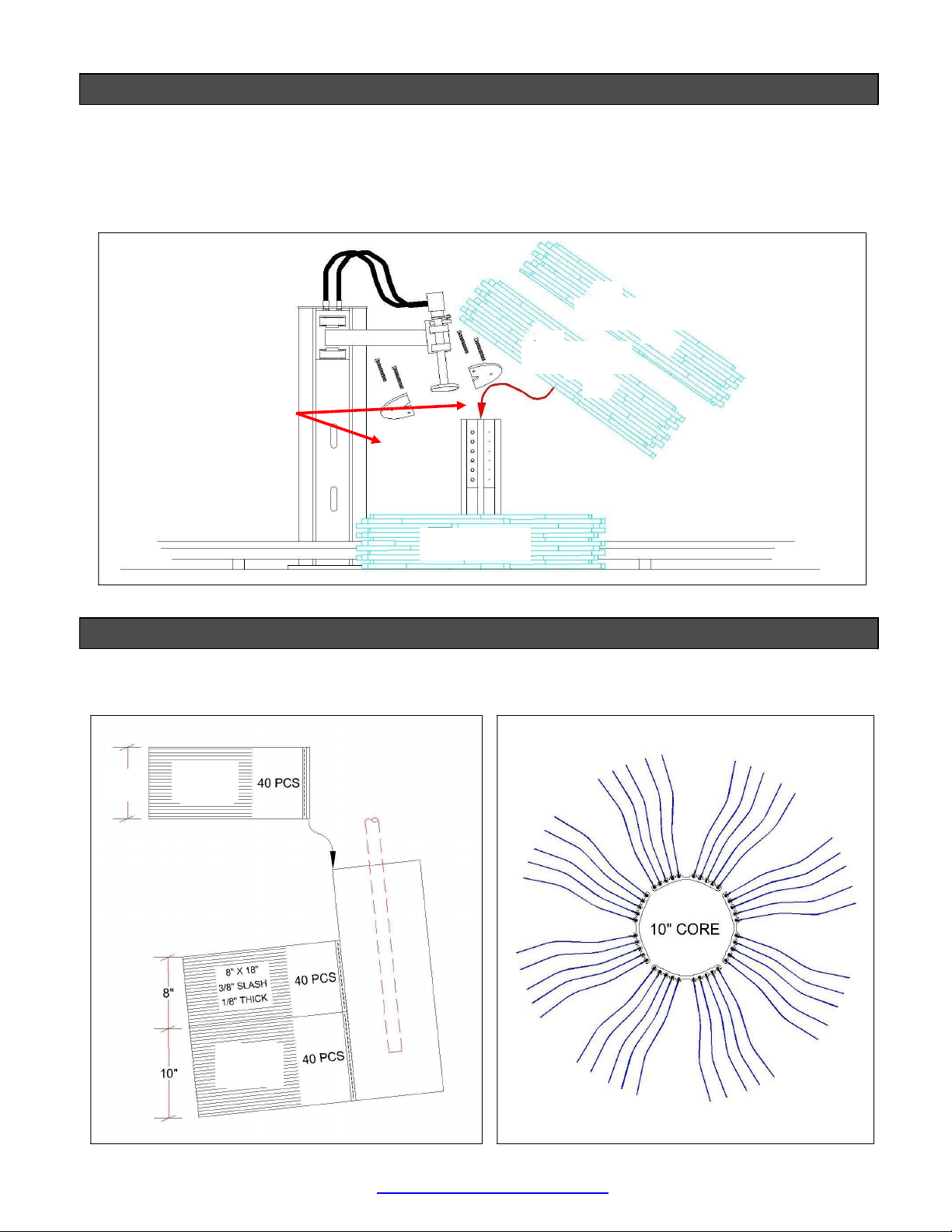

Color Skinz™ Snap On Structure Wrap

Bulk head utility connection fittings

Available in either C-Channel Foam or Cotton Cloth™ wash material

Suggested Installation Tools and Materials

Hammer Drill with 5/8” Drill Bit (8) Wedge Anchor Bolts 5/8” x 6”

Sledge Hammer Safety Goggles

Set of Standard Combo Wrenches Torpedo Level

Measuring Tape Safety Goggles

HYDRAULIC DRIVE

ROCKRHYD[…….]

ELECTRIC DRIVE

ROCKRELE[…….]

ELECTRICAL N/A

MOTORS: 2 HP (2 X 1.0 HP)

9.2-4.2 AMP @ 208-460 VAC, 3 PH

UL® RECOGNIZED, CSA CERTIFIED, CE MARK, IEC IP 55

HYDRAULIC 3 GPM @ 1000 PSI N/A

PNEUMATICS

N/A N/A

WATER RECLAIMED OR FRESH:

2 GPM @ 40 PSI

RECLAIMED OR FRESH:

2 GPM @ 40 PSI