SAFEGUARDS ML900 HYDRAULIC LIFT

1-5

CHAPTER 1. SAFEGUARDS

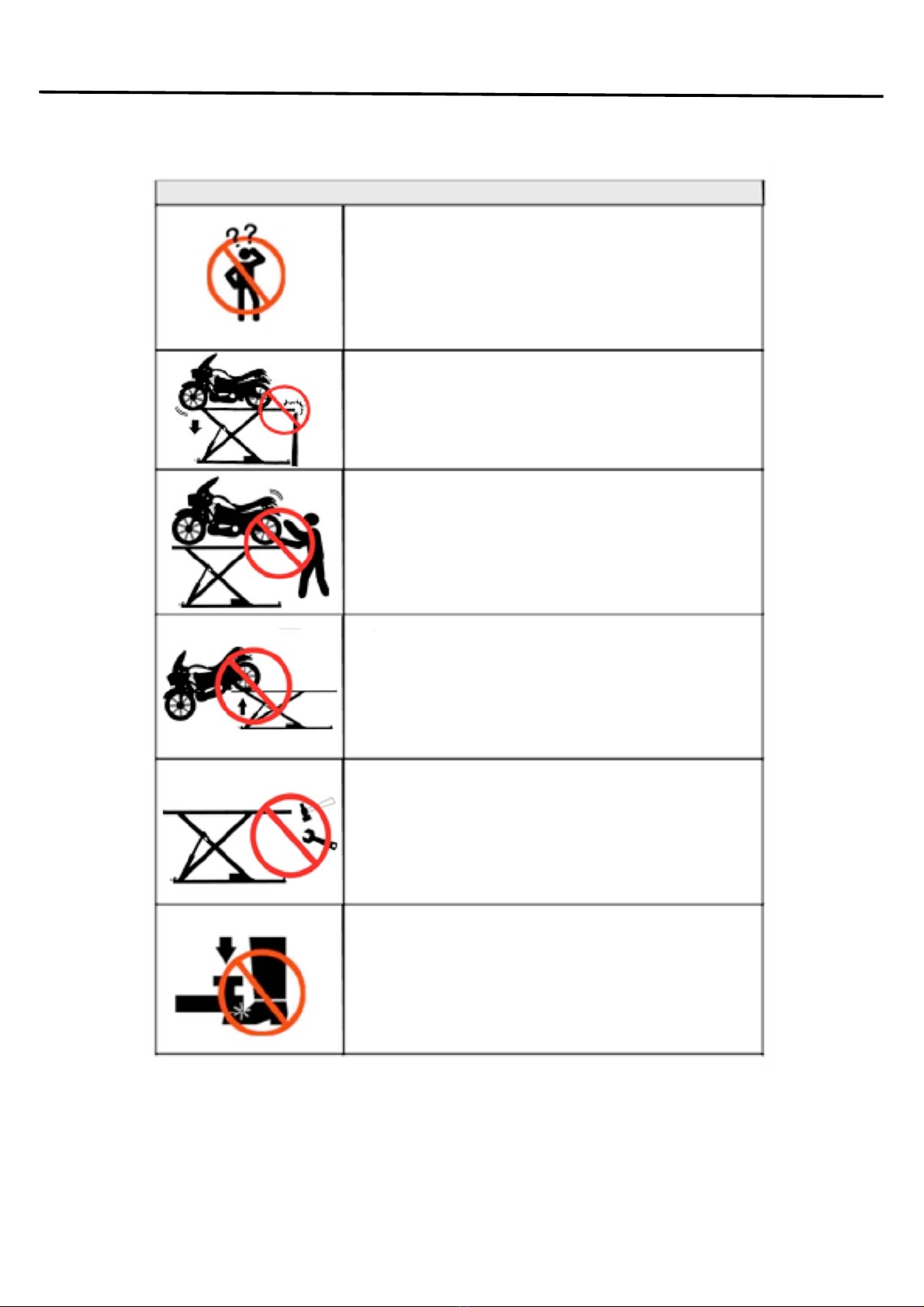

Please read this chapter carefully forsafe and proper use of the motorcycle lift.

MOTORLIJN will not be held responsibilities for any injuries or accidents that

occur due to the motorcycle lift being operated without having understood the

contents of this instruction manual. Keep the Instruction Manual close to the

motorcycle lift so that anyone canrefer to it when necessary. Also, designate a

person totake care of the manual.

1-1 Important Notices

A Motorcycle lift must be considered to be a potential hazard to the health

and safety of the motorcycle lift's operator and service personnel. It is

important that this motorcycle lift is installed, maintained, and operated

according to the instructions set out within this manual. This is a

responsibility imposed on the customer by the EU Council Directive

89/655/EEC, concerning the minimum safety and health requirements for

the use of work equipment by workers at work.

Any modification, alteration oraddition to the motorcycle lift orthe fitting of

ancillary equipment must comply with the EUCouncil Directive(s).

MOTORLIJN does notaccept anyliability whatsoever, which may result in

legal action from failure tocomply with these regulations, or any

consequential loss, claim or counter claim for damage, personal injury, or

death arising as a result of anymodification, alteration or addition to the to

the motorcycle lift or the fitting of ancillary equipment.

EU Council Machinery Directive 98/37/EC

The above machinery directive requires all new machinery to carry the CE

mark, declaring conformity with all relevant EN standards in respect of safety

systems and motorcycle lift construction.

All MOTORLIJN MACHINERY carries theCE mark and thus conforms to

theEU Directives. Any modification to the motorcycle lift mayinvalidate the

original CE certificate; therefore always refer to MOTORLIJN.as reassessment

may be required.

This document provides the information required for the intended use of

lifting a motorcycle. The documentation is written for technically qualified

personnel such as engineers or maintenance specialists who have been