function of the SET key can be replaced with the radio control,

if programmed previously (CODE LED on).

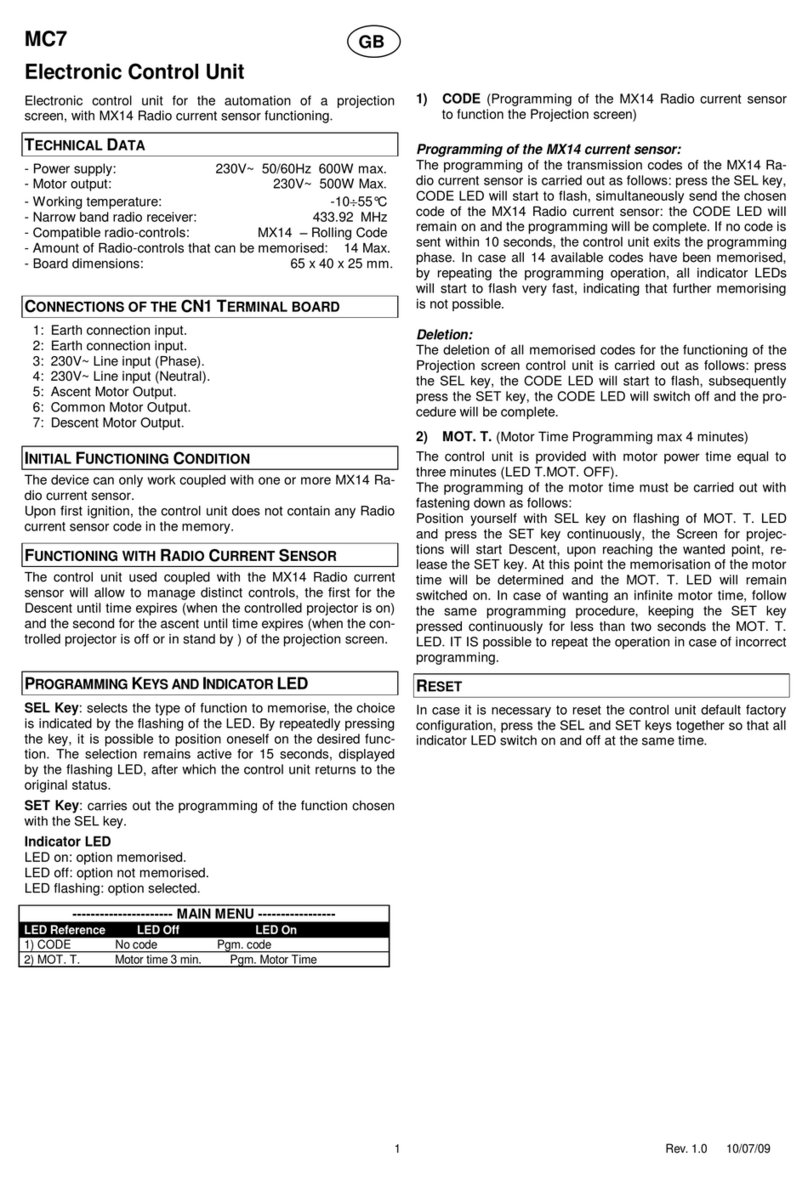

MAIN MENU

The control unit is supplied by the manufacturer with the

possibility of selecting some important functions.

---------------------- MAIN MENU -----------------

LED status LED off LED on

1) AUT / P-P Automatic Step-by-Step

2) CODE No code Code entered

3) CODE PED. No code Code entered

4) INB.CMD.AP Not enabled Enabled

5) T. MOT. 30 sec. motor time Programmed time

) T.MOT.PED. 10 sec. Mot. Ped. Time Programmed time

7) T. PAUSA. Without aut. closing With aut. closing

8) RIT. ANTE Without door delay. Programmed time

1) AUTOMATIC / STEP-BY-STEP:

The control unit is supplied by default with the “Automatic”

operation feature enabled (AUT/P-P LED off). To enable the

“Step-by-Step” operation feature (AUT/P-P LED on) follow this

procedure: with the SEL key go to AUT/P-P LED when flashing

and press the SET key: the AUT/P-P LED turns on. Repeat the

operation to restore the previous configuration.

2) CODE : (Radio control code)

The control unit allows for storing 150 radio controls with

different code of fixed or rolling type.

Programming.

To programme the transmission code follow this procedure:

with the SEL key go to CODE LED when flashing, send the

desired code with the radio control; programming is completed

when the CODE LED remains on permanently. If you have

stored 150 codes and you repeat the programming operation,

all programming LED’s start flashing to indicate that no codes

can be stored.

Deleting the codes.

To delete all transmission codes stored in the memory, do as

follows: press the SEL key, the CODE LED starts flashing, then

press the SET key, the LED CODE turns off and the procedure

is completed.

3) CODE PED:(Code of Pedestrian / Left Door radio control).

The programming and deleting procedure is the same as the

one illustrated above, with reference to the CODE PED. LED.

4) INB. CMD. AP: (command inhibition during opening and

pause time, if entered)

The command inhibition function during opening and pause

time, if entered, is used when automation includes the loop

detector. During opening or pause the control unit does not

detect the commands given by the loop detector at every

passage.

The control unit is supplied by default with the command

inhibition function during opening and pause time not enabled.

To enable the function follow this procedure: with the SEL key

go to INB.CMD.AP LED when flashing, then press the SET key:

the INB.CMD.AP turns on. Repeat the operation to restore the

previous configuration.

5) MOTOR TIME and DECELERATION: (Programming motor

operation time of max. 4 minutes)

The control unit is supplied by the manufacturer with predefined

motor operation time of 30 seconds without deceleration.

To modify the motor operation time, follow this procedure with

the shutter closed: with the SEL key go to T.MOT. LED when

flashing, then press the SET key rapidly, Motor 1 starts the

opening cycle; when the initial point of deceleration is reached

press the SET key again, the motor decelerates until the

desired position is reached, press the SET key to complete the

opening cycle. The T.MOT. LED starts flashing rapidly, now

repeat the programming operation for Motor 2 motor operation

time and deceleration. When the motor operation time is

programmed for opening, the T.MOT. LED starts flashing

rapidly, now repeat the programming operation for closing. To

deactivate the deceleration function, during programming, once

the opening and closing cycle is completed, press the SET key

twice in a sequence.

During programming the radio control key of the control unit

can be used instead of the ET key, if stored previously.

6) T. MOT. PED: (Programming pedestrian operation time of max. 4

minutes)

The control unit is supplied by the manufacturer with predefined

operation time of Motor 1 (Pedestrian) of 10 seconds without

deceleration.

To modify the pedestrian operation time, follow this procedure

with the shutter closed: with the SEL key go to T.MOT.PED.

LED when flashing, then press the SET key rapidly, Motor 1

starts the opening cycle; when the initial point of deceleration is

reached press the SET key again, the motor decelerates until

the desired position is reached, press the SET key to complete

the opening cycle. The T.MOT.PED LED starts flashing rapidly,

now repeat the programming operation for closing. To

deactivate the deceleration function, during programming, once

the opening and closing cycle is completed, press the SET key

twice in a sequence.

During programming the radio control key of the control unit

can be used instead of the ET key, if stored previously.

7) T. PAUSA: (Programming of aut. closing time of max. 4 min.)

The control unit is supplied by the manufacturer without

automatic closing. To enable the automatic closing function

follow this procedure: with the SEL key go to T.PAUSA when

flashing, then press the SET key, wait for the desired interval of

time, then press the SET key again; the automatic closing time

is stored and the T.PAUSA LED is on. To restore the initial

configuration (without automatic closing) go to the T.PAUSA

LED when flashing then press the SET key twice within 2

seconds; the LED goes off and the operation is completed.

During programming the radio control key of the control unit

can be used instead of the ET key, if stored previously.

8) T. RIT. ANTE : (Programming door delay of max. 15 sec.)

The control unit is supplied by the manufacturer without door

delay during opening and closing. To programme the door

delay time, follow this procedure with the shutter closed: with

the SEL key to the RIT.ANTE LED when flashing, press the

SET key, wait for the desired interval of time, then press the

SET key again; the fixed door delay time of 2 seconds during

opening is stored, the door delay time during closing is stored

for the programmed time and the RIT.ANTE LED is on.

To restore the initial configuration (without door delay) go to the

RIT.ANTE LED when flashing then press the SET key twice

within 2 seconds; the LED goes off and the operation is

completed.

EXTENDED MENU

The control unit is supplied by the manufacturer with the

possibility of selecting only the functions of the main menu.

To enable the functions of the extended menu follow this

procedure: hold the SET key pressed for 5 seconds; the

T.PAUSA and RIT.ANTE LED’s start flashing alternatively; the

user has 30 seconds time to select the functions of the

extended menu with the SEL and SET keys, after 30 seconds

the control unit returns to the main menu.

---------------------- EXTENDED MENU -----------------

LED status LED off LED on

A) AUT / P-P remote PGM = OFF remote PGM = ON

B) CODE Photoelectric cells test = ON Photoelectric cells test =

OFF

C) CODE PED. Pressure Maint. = OFF Pressure

Maint. = ON

D) INB.CMD.AP The aries effect = OFF The aries effect = ON

E) T. MOT. Closure Strike = OFF Closure Strike = ON

F) T.MOT.PED. Safety device 2 Stop input