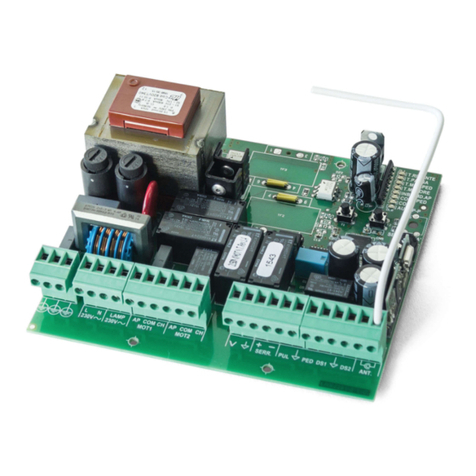

. THE CONTROL BOARD . THE CONTROL BOARD

TECHNICAL CHARACTERISTICS

Before proceeding to the control board configuration, note the following points listed

in the table below to better understand the control board's functions:

• PROGRAMMING PRERECOMENDATIONS

CN2CN2 CN1

Flashing / Courtesy light:

03 and 04 •This output allows connection of a 110V / 230V courtesy light or a

flashing light (see page 2). This output does not flash.

CN2

Step by step pushbutton:

03 and 04• This input (NO) allows to control the control board through

pushbuttons. When you receive the first order, it triggers the opening until the

motor's working time ends or until it detects the opening limit switch.

When it receives a second order, it triggers the closing.

If you receive an order during the opening or closing of the gate, the movement

stops and it's only restored (in the opposite direction from what it was before it

stops) after receiving a new order. During opening, if it receives a order to stop

(active T.PAUSA), it will temporize and close the gate.

CN2

TIMER functioning:

03 and 04 • The control board allows a connection of a TIMER. With this

device, you can set an exact time for the gate to perform the opening / closing

automatically. For example: If you program a time between 8 am and 10 am,

this will cause an opening contact at 8 am and will maintain the contact until

10am. At 10am, the gate will perform the closing, after waiting the pause time.

(It is important to enable automatic closure)

CN2

Safety circuits:

05 • This circuit allows photocells connection.

This device operates only in the gate closure, and when triggered, reverses the

direction gate movement.

CN2

Limit-switches:

06 to 08 • The control board needs the connection limit switches in opening

and closing (both NC). The trigger of any one of the limit switches causes the

immediate stop of the gate's movement.The limit switches triggering is signaled

by the LEDs FCH and FAP. When a limit switch is activated,the respective LED

goes off. The LED FAP corresponds to opening limit switch and the LED FCH to

the closing limit switch.

If you do not use limit switches (swing gate) should close with a shunt circuits

6-7 and/or 7-8 of the CN2 connector. It is mandatory the use of limit switches

on sliding gate motors!

• CONNECTOR’S DESCRIPTION

TECHNICAL CHARACTERISTICS

• Power Supply 110V or 230V AC | 50-60Hz | 900W max. (4A)

• Lightbulb or courtesy light output 110V/230V AC 500W max.

100W (max. resistive cargo)

50W (max. induced cargo)

• Motor’s output 110V/230V AC 50/60Hz 750W max.

• Output for powering accessories 24V AC 3W max.

• Working temperature -10°C to +55°C

• Incorporated Radio Receiver 433,92 Mhz

• Code types 12-18 bits or Rolling Code

• Maximum memory capacity 120 codes (CODE or CODE PED)

• Control board dimensions 108x138 mm

CN1

01 • 110V/230V Line Input (PHASE)

02 • 110V/230V Line Input (NEUTRAL)

03 • Lightbulb / Courtesy light’s output (GND/COM)

04 • Lightbulb / Courtesy light’s output (phase)

05 • Motor’s Output (opening)

06 • Motor’s Output (GND/COM)

07 • Motor’s Output (closing)

CN2

01 • Output for powering photocells (24V AC - 6W Max.)

02 • Output for powering photocells (GND/COM)

03 • Step-by-step pushbutton input (NO)

04 • GND/COM output

05 • Security devices input (NC)

06 • Opening limit-switch input (NC)

07 • GND/COM output

08 • Closing limit-switch input (NC)

09 • Antenna input (mass)

10 • Antenna input (hot pole)

ATTENTION

to output:

The output voltage depends on the supply voltage ( and )