1 Rev. 1.0 10/07/09

MC7

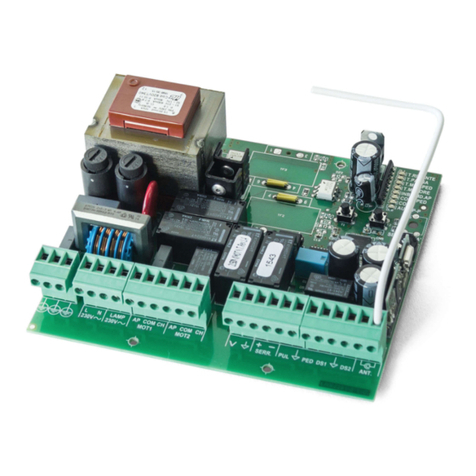

Electronic Control Unit

Electronic control unit for the automation of a projection

screen, with MX14 Radio current sensor functioning.

TECHNICAL DATA

- Power supply: 230V~ 50/60Hz 600W max.

- Motor output: 230V~ 500W Max.

- Working temperature: -10 55°C

- Narrow band radio receiver: 433.92 MHz

- Compatible radio-controls: MX14 –Rolling Code

- Amount of Radio-controls that can be memorised: 14 Max.

- Board dimensions: 65 x 40 x 25 mm.

CONNECTIONS OF THE CN1 TERMINAL BOARD

1: Earth connection input.

2: Earth connection input.

3: 230V~ Line input (Phase).

4: 230V~ Line input (Neutral).

5: Ascent Motor Output.

6: Common Motor Output.

7: Descent Motor Output.

INITIAL FUNCTIONING CONDITION

The device can only work coupled with one or more MX14 Ra-

dio current sensor.

Upon first ignition, the control unit does not contain any Radio

current sensor code in the memory.

FUNCTIONING WITH RADIO CURRENT SENSOR

The control unit used coupled with the MX14 Radio current

sensor will allow to manage distinct controls, the first for the

Descent until time expires (when the controlled projector is on)

and the second for the ascent until time expires (when the con-

trolled projector is off or in stand by ) of the projection screen.

PROGRAMMING KEYS AND INDICATOR LED

SEL Key: selects the type of function to memorise, the choice

is indicated by the flashing of the LED. By repeatedly pressing

the key, it is possible to position oneself on the desired func-

tion. The selection remains active for 15 seconds, displayed

by the flashing LED, after which the control unit returns to the

original status.

SET Key: carries out the programming of the function chosen

with the SEL key.

Indicator LED

LED on: option memorised.

LED off: option not memorised.

LED flashing: option selected.

---------------------- MAIN MENU -----------------

LED Reference LED Off LED On

1) CODE No code Pgm. code

2) MOT. T. Motor time3 min. Pgm. Motor Time

1) CODE (Programming of the MX14 Radio current sensor

to function the Projection screen)

Programming of the MX14 current sensor:

The programming of the transmission codes of the MX14 Ra-

dio current sensor is carried out as follows: press the SEL key,

CODE LED will start to flash, simultaneously send the chosen

code of the MX14 Radio current sensor: the CODE LED will

remain on and the programming will be complete. If no code is

sent within 10 seconds, the control unit exits the programming

phase. In case all 14 available codes have been memorised,

by repeating the programming operation, all indicator LEDs

will start to flash very fast, indicating that further memorising

is not possible.

Deletion:

The deletion of all memorised codes for the functioning of the

Projection screen control unit is carried out as follows: press

the SEL key, the CODE LED will start to flash, subsequently

press the SET key, the CODE LED will switch off and the pro-

cedure will be complete.

2) MOT. T. (Motor Time Programming max 4 minutes)

The control unit is provided with motor power time equal to

three minutes (LED T.MOT. OFF).

The programming of the motor time must be carried out with

fastening down as follows:

Position yourself with SEL key on flashing of MOT. T. LED

and press the SET key continuously, the Screen for projec-

tions will start Descent, upon reaching the wanted point, re-

lease the SET key. At this point the memorisation of the motor

time will be determined and the MOT. T. LED will remain

switched on. In case of wanting an infinite motor time, follow

the same programming procedure, keeping the SET key

pressed continuously for less than two seconds the MOT. T.

LED. IT IS possible to repeat the operation in case of incorrect

programming.

RESET

In case it is necessary to reset the control unit default factory

configuration, press the SEL and SET keys together so that all

indicator LED switch on and off at the same time.