3.0 07/2009 - The data and information in this manual are subject to change at any time.

INDEX

1.0 General characteristics pag. 2

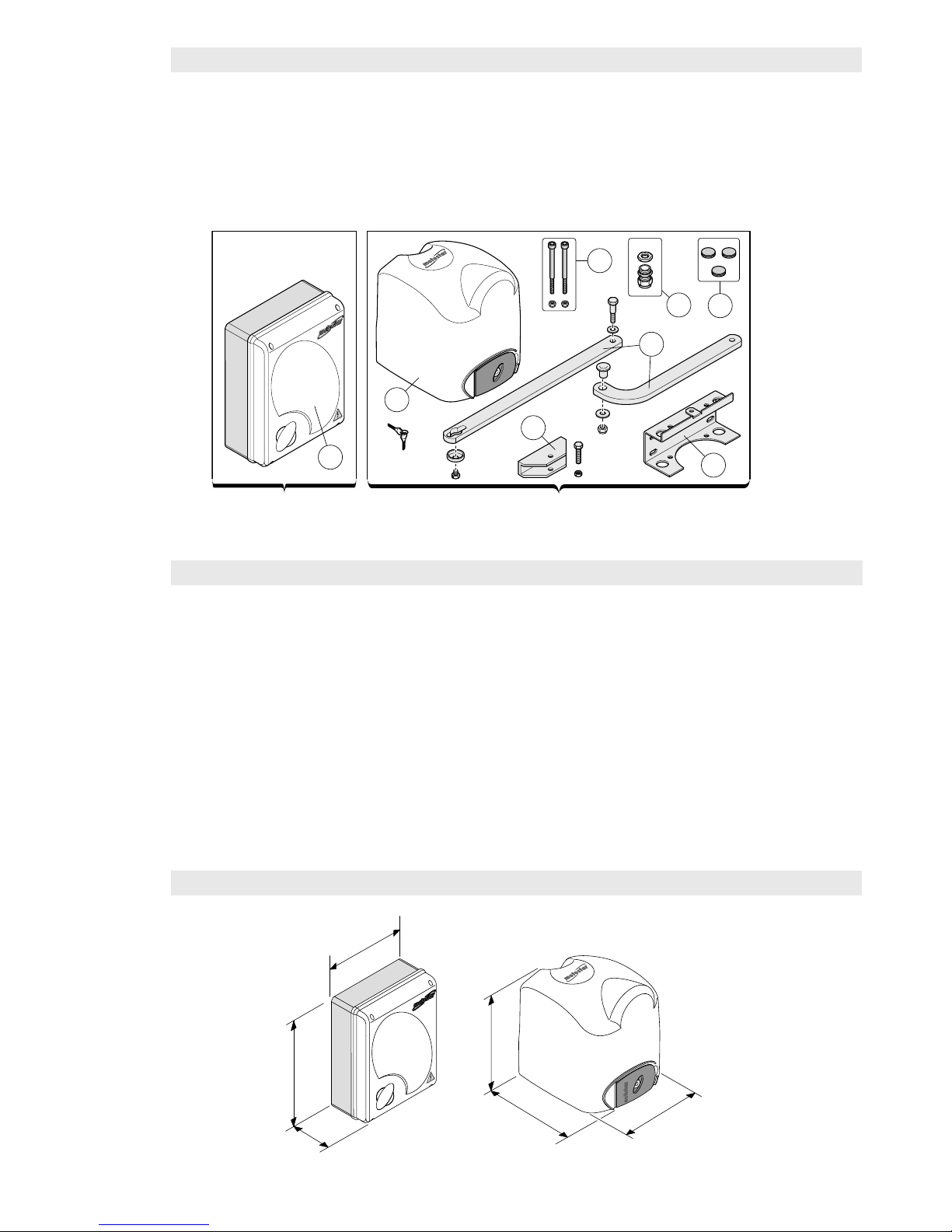

1.1 Components pag. 3

1.2 Technical features pag. 3

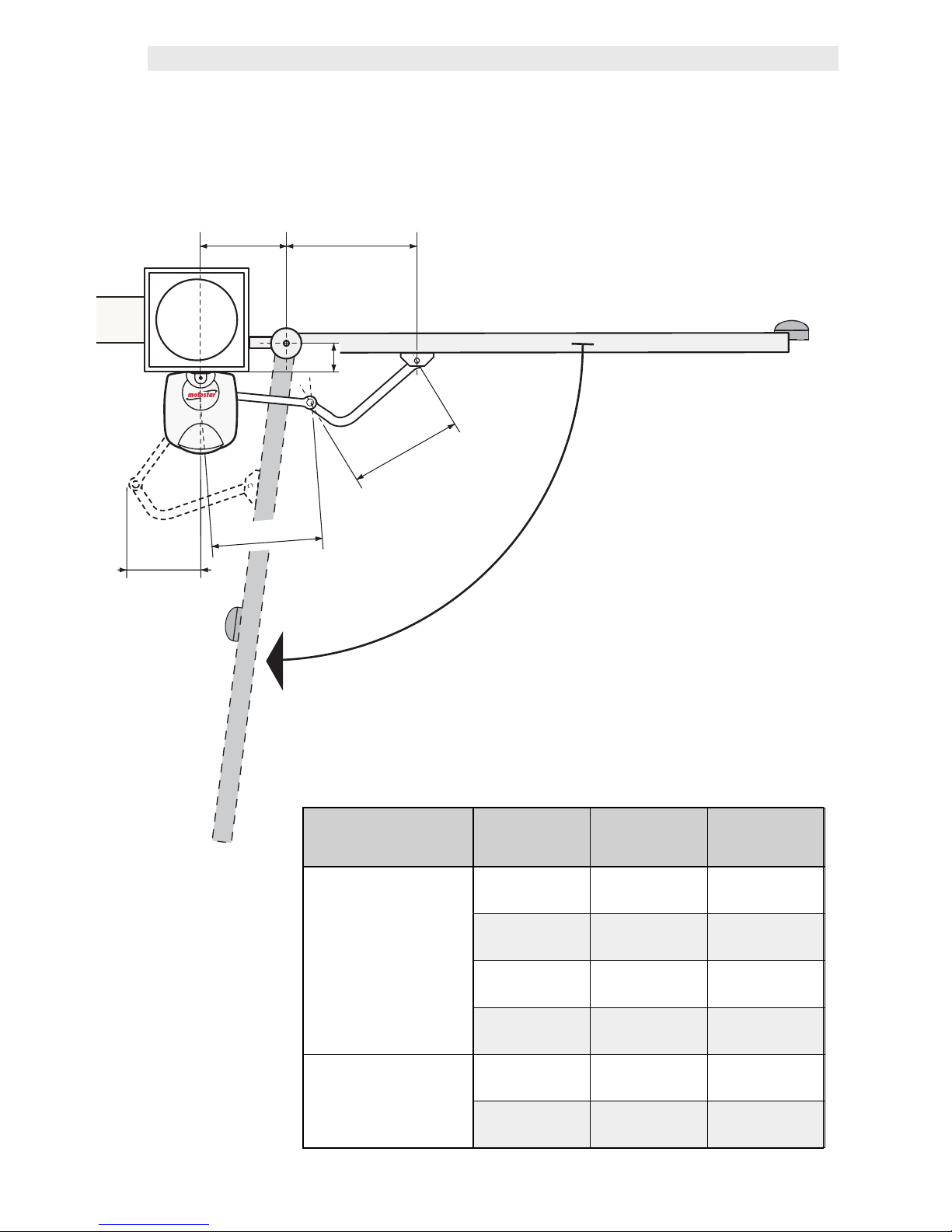

1.3 Dimensions pag. 3

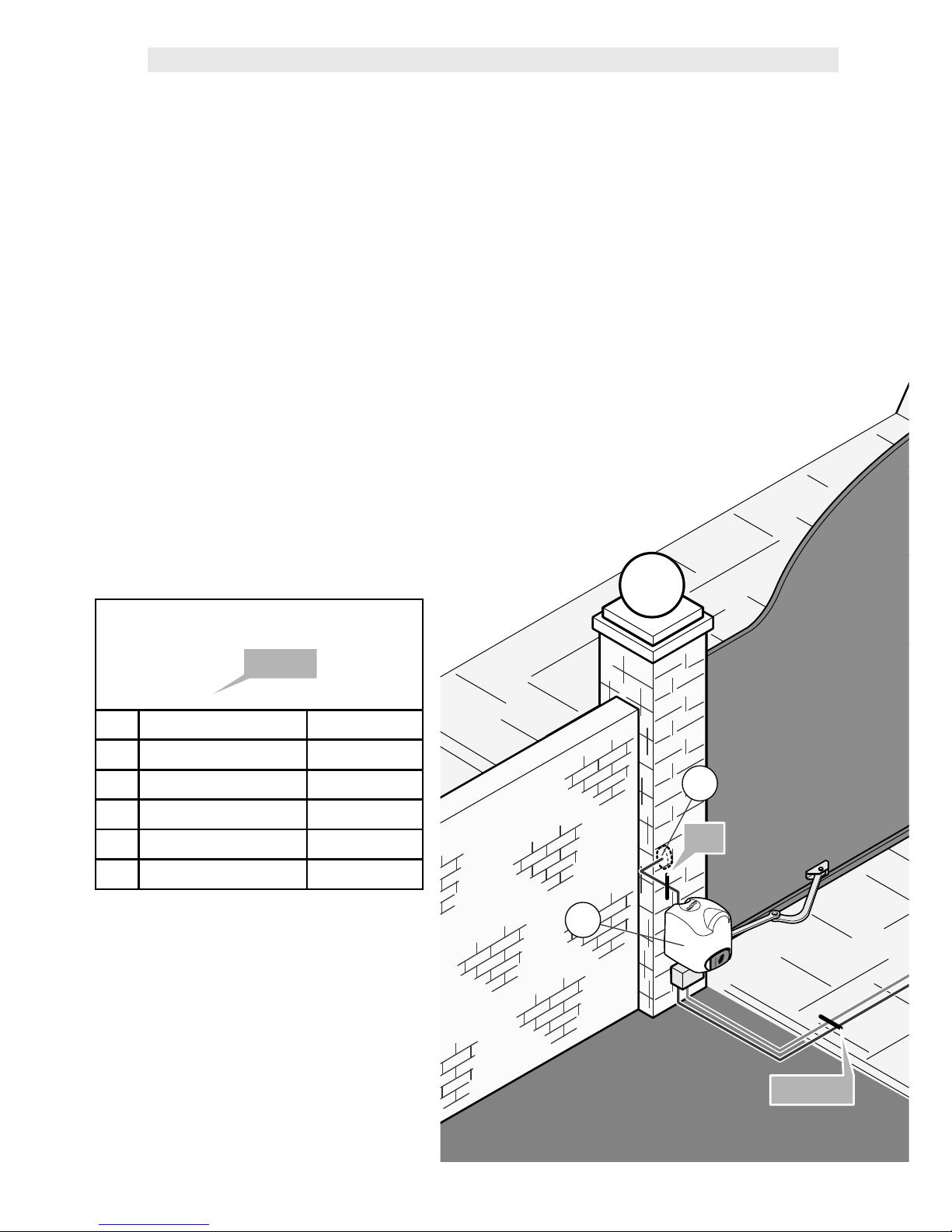

1.4 Main component parts of a standard installation pag. 4

1.5 Limits to use pag. 6

2.0 Installing the gearmotor pag. 7

3.0 Control panel pag. 18

3.1 Assembling and fixing the casing pag. 20

3.2 Control board and its functions – description pag. 22

3.3 Electrical connections pag. 23

3.4 Selecting functions pag. 27

3.5 Adjusting functions pag. 29

3.6 Checking endstops adjustments pag. 30

3.7 Programming the radio code pag. 31

3.8 Control LEDs’ functions pag. 32

3.9 Final operations pag. 32

4.0 Warnings and precautions pag. 33

5.0 Troubleshooting pag. 33

6.0 Maintenance pag. 34

7.0 Dismissal and disposal pag. 36

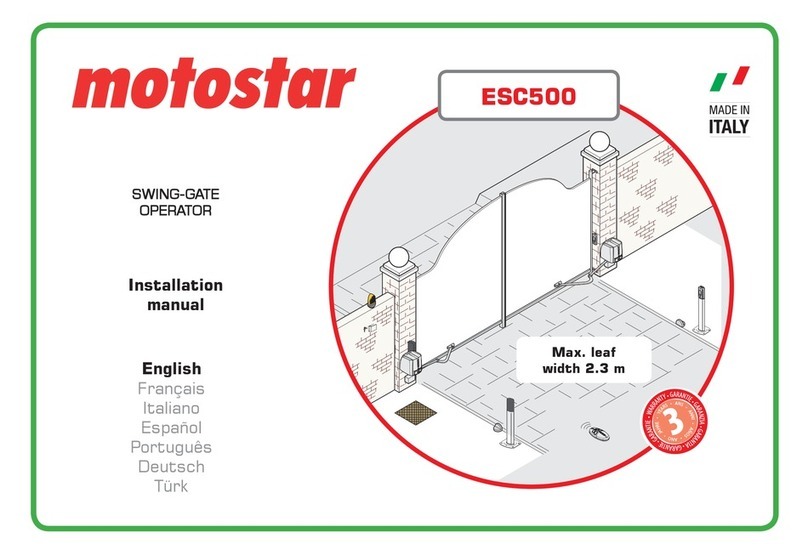

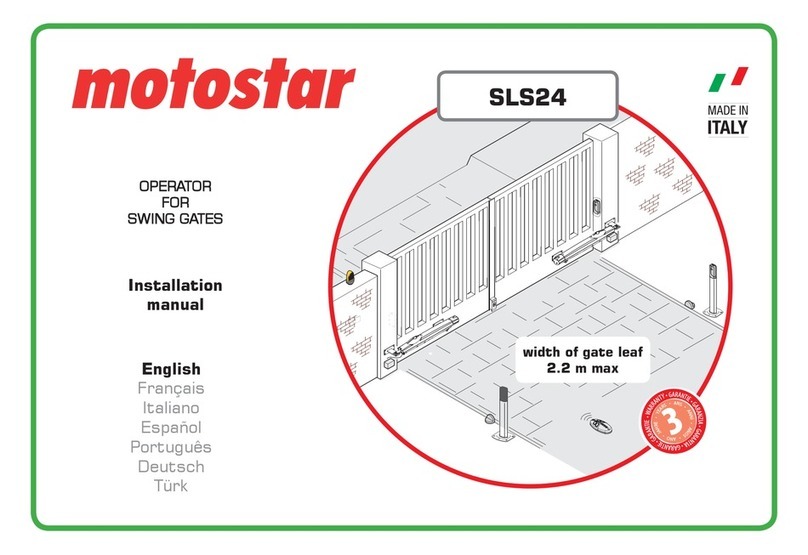

1.0 GENERAL CHARACTERISTICS

Operator for swing gates up to 2.20 m per gate leaf, 230V A.C. powered, IP54 protection

rating, fitted with:

- autoapprendimento del codice tra trasmettitore e ricevitore radio;

- self-learning of the code between transmitter and radio receiver;

- adjustable amperometric detector for movement inversion of the opening and closing gate

leaves;

- colour-coded terminals to identify the various accessories and simplify connections;

- power up warning LEDs, programming and safety test;

- endstops for managing gate leaf stops when opening and slow-downs when closing;

- emergency release with customised key;

- power cable L = 2.5 m.