2

-

FG00666M07

-

1

- 03/2017

ENGLISH

Summary

GENERAL WARNINGS ................................................................3

KEY...........................................................................................5

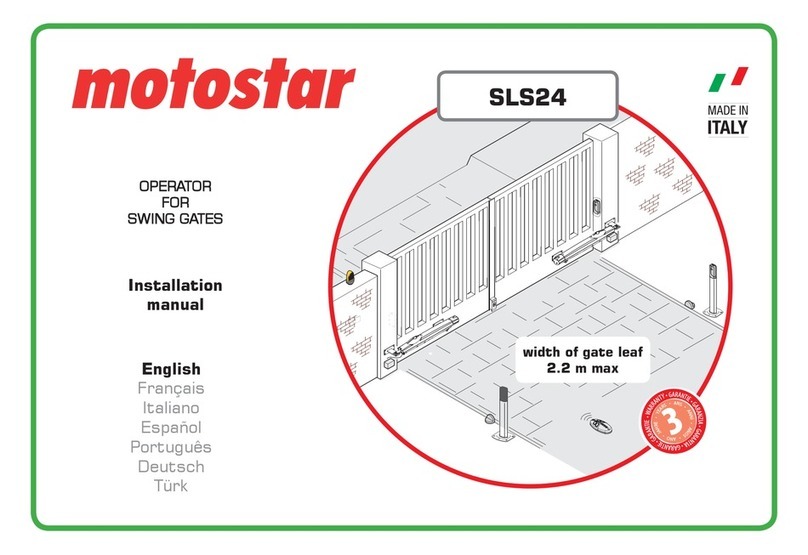

DESCRIPTION . .......................................................................... 5

Intended use .........................................................5

Limits to use .........................................................5

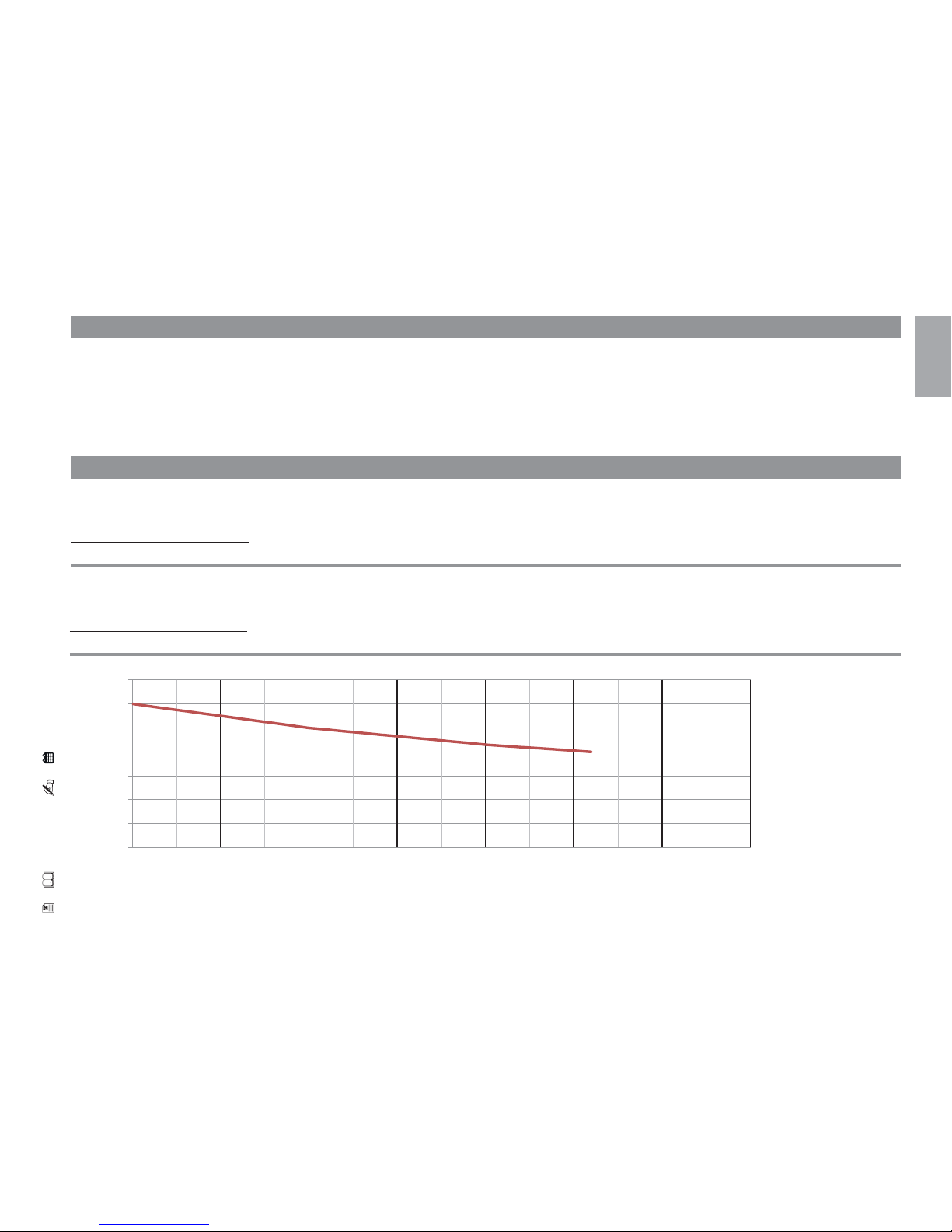

Technical data... ....................................................6

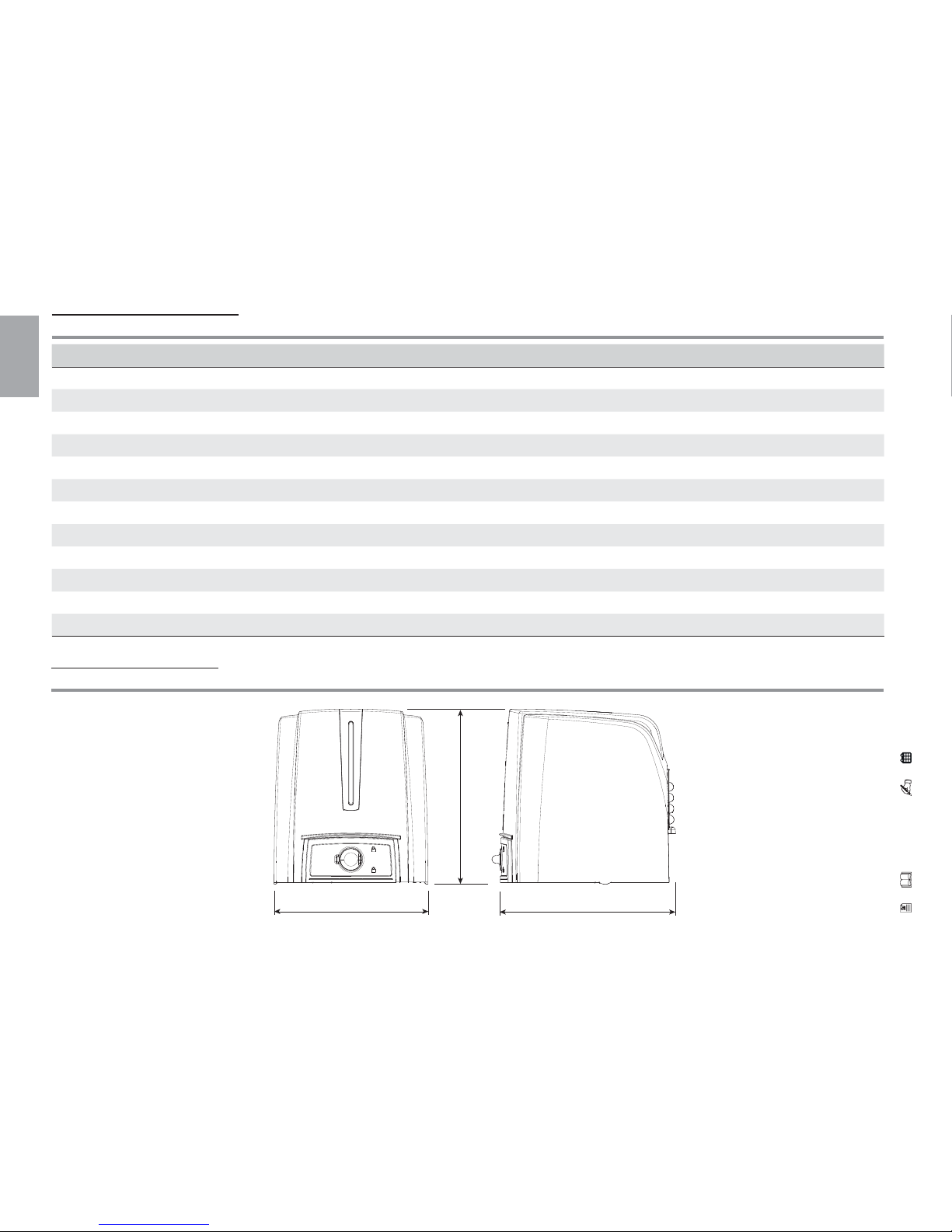

Dimensions.. .........................................................6

Description of parts ... ...........................................7

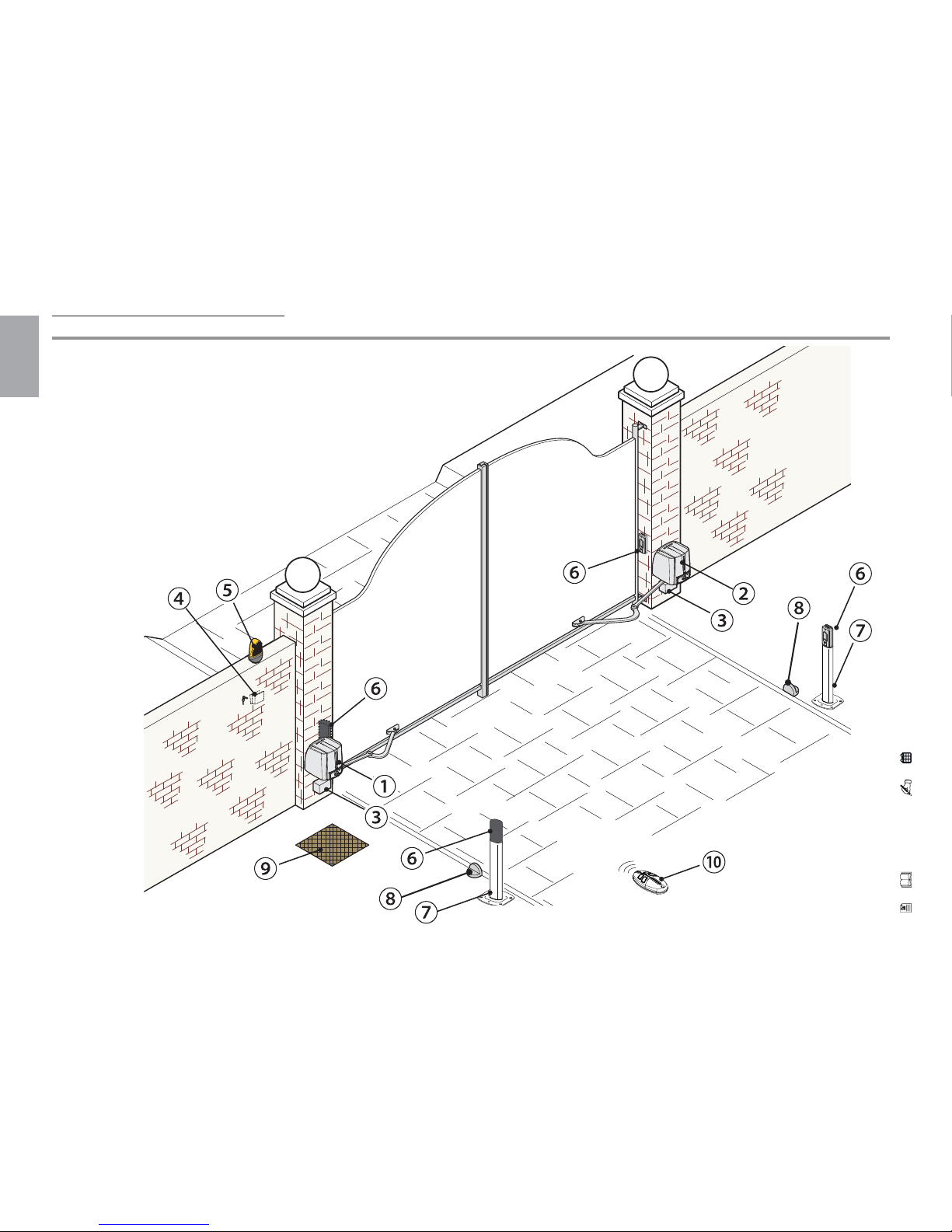

Standard installation .. ...........................................8

INSTALLATION .......................................................................... 9

Preliminary checks . ...............................................9

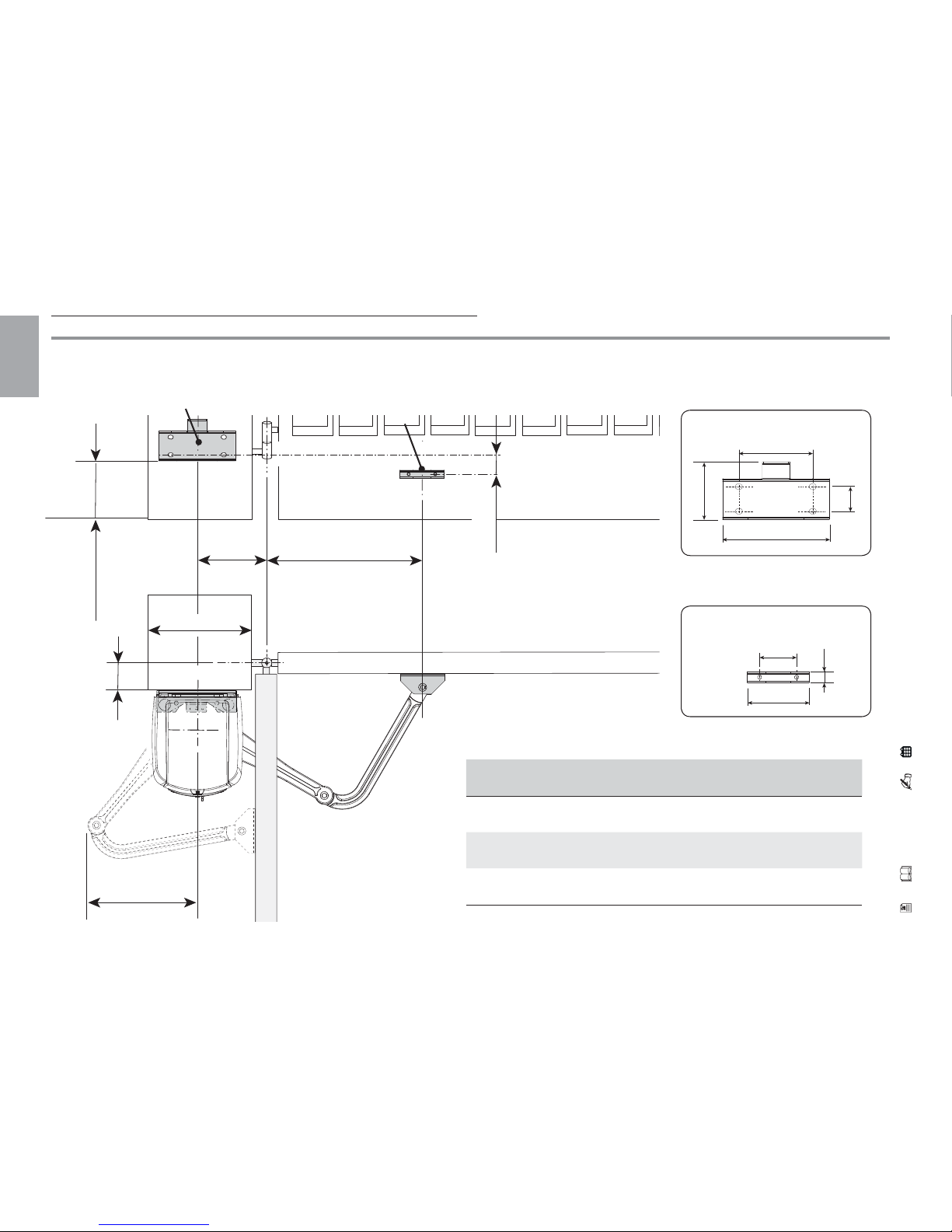

Checking the application measurements and sizes ... 10

Cable type and minimum thicknesses ... ................. 11

Preliminary operations ......................................... 12

Fastening the brackets......................................... 13

Fastening the operator.... .................................... 15

Fastening the mechanical stops............................. 18

Establishing the limit-switch points. ...................... 20

CONTROL BOARD .. .................................................................. 22

Main components .. ............................................. 22

ELECTRICAL CONNECTIONS .... ................................................. 23

Power supply.... .................................................. 23

Solenoid lock ....................................................... 23

Operator and gearmotor . .................................... 24

Command and control devices ............................... 26

Safety devices .. .................................................. 27

Signalling devices ... ............................................. 28

PROGRAMMING... .................................................................. 29

Description of programming commands ................. 29

Functions menu .................................................. 30

SETTING UP.... ........................................................................36

Motor type . ....................................................... 36

Number of motors . ............................................. 36

Motor test.. ....................................................... 37

Self-learning of the gate-leaf travel. ...................... 38

USER MANAGEMENT ...............................................................40

Entering a user with an associated command ......... 40

Deleting a single user. ......................................... 41

ILLUSTRATION OF THE SLOW-DOWN AND APPROACH AREAS AND

POINTS ...................................................................................42

ERROR MESSAGE.. ..................................................................43

FINAL OPERATIONS..................................................................43

OUTWARD OPENING CONNECTIONS AND INSTALLATIONS.. ......44

Application measurements and sizes ...................... 44

Fastening the mechanical stops............................. 45

Establishing the limit-switch points. ...................... 45

Electrical connections. ......................................... 46

DISMANTLING AND DISPOSAL .................................................48

DECLARATION OF CONFORMITY................................................48