Motrona DZ 270 User manual

control – motion – interface

motrona GmbH

Zwischen den Wegen 32

78239 Rielasingen - Germany

Tel. +49 (0)7731-9332-0

Fax +49 (0)7731-9332-30

www.motrona.com

DZ27001a_e.doc / Jan-13 Page 1 / 36

DZ 270, 271, 276, 277, 279

Universal Monitors for Speed,

Standstill, Direction of Rotation

DZ270: Monitor with 3 programmable output relays and 1 analogue output

DZ271: Monitor with 3 programmable transistor outputs and 1 analogue output

DZ276: Monitor with 1 analogue output only

DZ277: Monitor with 3 programmable output relays only

DZ279: Monitor with 3 programmable transistor outputs only

Compact and most versatile monitor series for control of overspeed, underspeed,

standstill and direction of rotation

Logical monitoring of remote motion enable signals

Input for connection to sin/cos encoders with 1 Vss format

Extremely wide frequency range up to 500 kHz

Easy setup by means of four keys and LCD menu

All models include serial RS232 interface

Operating Instructions

DZ27001a_e.doc / Jan-13 Page 2 / 36

Safety Instructions

This manual is an essential part of the unit and contains important hints about

function, correct handling and commissioning. Non-observance can result in

damage to the unit or the machine or even in injury to persons using the

equipment!

The unit must only be installed, connected and activated by a qualified electrician

It is a must to observe all general and also all country-specific and application-

specific safety standards

When this unit is used with applications where failure or maloperation could cause

damage to a machine or hazard to the operating staff, it is indispensable to meet

effective precautions in order to avoid such consequences

Regarding installation, wiring, environmental conditions, screening of cables and

earthing, you must follow the general standards of industrial automation industry

- Errors and omissions excepted –

General instructions for cabling, screening and grounding can be found in the

SUPPORT section of our website http://www.motrona.com

Version:

Description:

DZ27

00

1

a_sn_12/12

First edition

DZ27001a_e.doc / Jan-13 Page 3 / 36

Table of Contents

1. Introduction ................................................................................................. 4

2. Available Models......................................................................................... 4

3. Electrical Connections ................................................................................. 5

3.1. Power Supply.......................................................................................................10

3.2. Auxiliary Output for Encoder Supply ...................................................................10

3.3. Inputs for SinCos Encoders and Sensors.............................................................10

3.4. Control Inputs ......................................................................................................10

3.5. Serial Interface....................................................................................................11

3.6. Relay Outputs K1 – K3 (DZ270 and DZ 277 only)................................................11

3.7. Tansistor Outputs K1 – K3 (DZ271 and DZ 279 only)..........................................11

3.8. Scalable Analogue Output (DZ270, DZ271 and DZ 276 only) .............................11

4. LCD Display and Keys ................................................................................ 12

5. Keypad Operation...................................................................................... 13

5.1. Normal Operation................................................................................................13

5.2. Keypad Interlock..................................................................................................13

5.3. General Setup Procedure ....................................................................................14

5.4. Changing Parameters on the Setting Level.........................................................14

5.5. Return from the Menu, Time-Out Function .........................................................15

5.6. Reset all Parameters to Factory Default Values .................................................15

6. Menu Structure and Parameter Description............................................... 16

6.1. Survey of Menus .................................................................................................16

6.2. Parameter Descriptions.......................................................................................17

7. Example for Commissioning....................................................................... 29

8. Appendix ................................................................................................... 31

8.1. Hints for Use of the Linearization Function.........................................................31

8.2. Data Readout via Serial Interface.......................................................................32

8.3. “Relay Action”, override relay states by programmed states.............................33

8.4. Monitoring of remote motion enable signals......................................................34

9. Specifications and Dimensions.................................................................. 35

DZ27001a_e.doc / Jan-13 Page 4 / 36

1. Introduction

This new series of monitors has been designed as control modules for mounting inside of

electric control cabinets. The units are suitable for speed monitoring of machines, signaling

overspeed, underspeed, zero motion and the direction of rotation. Units providing an analogue

output can moreover be used for closed-loop control or feedback purpose within a control

system.

Very special advantages of these new monitors are the wide frequency range, the extremely

fast response and the remarkable versatility with regard to possible programmable monitoring

functions.

2. Available Models

There are five models available, all with fully similar basic functions, but with different options

concerning the outputs.

DZ = Function: Speed Monitor

DZ 270

27 = Housing with dimensions 72 x 91 mm

(2.835 x 3.583 ‘’), with LCD and keypad

0 = Analogue output + 3 relay outputs

1 = Anlaouge output + 3 transistor outputs

6 = Analogue output only

7 = Relay outputs only

9 = Transistor outputs only

DZ27001a_e.doc / Jan-13 Page 5 / 36

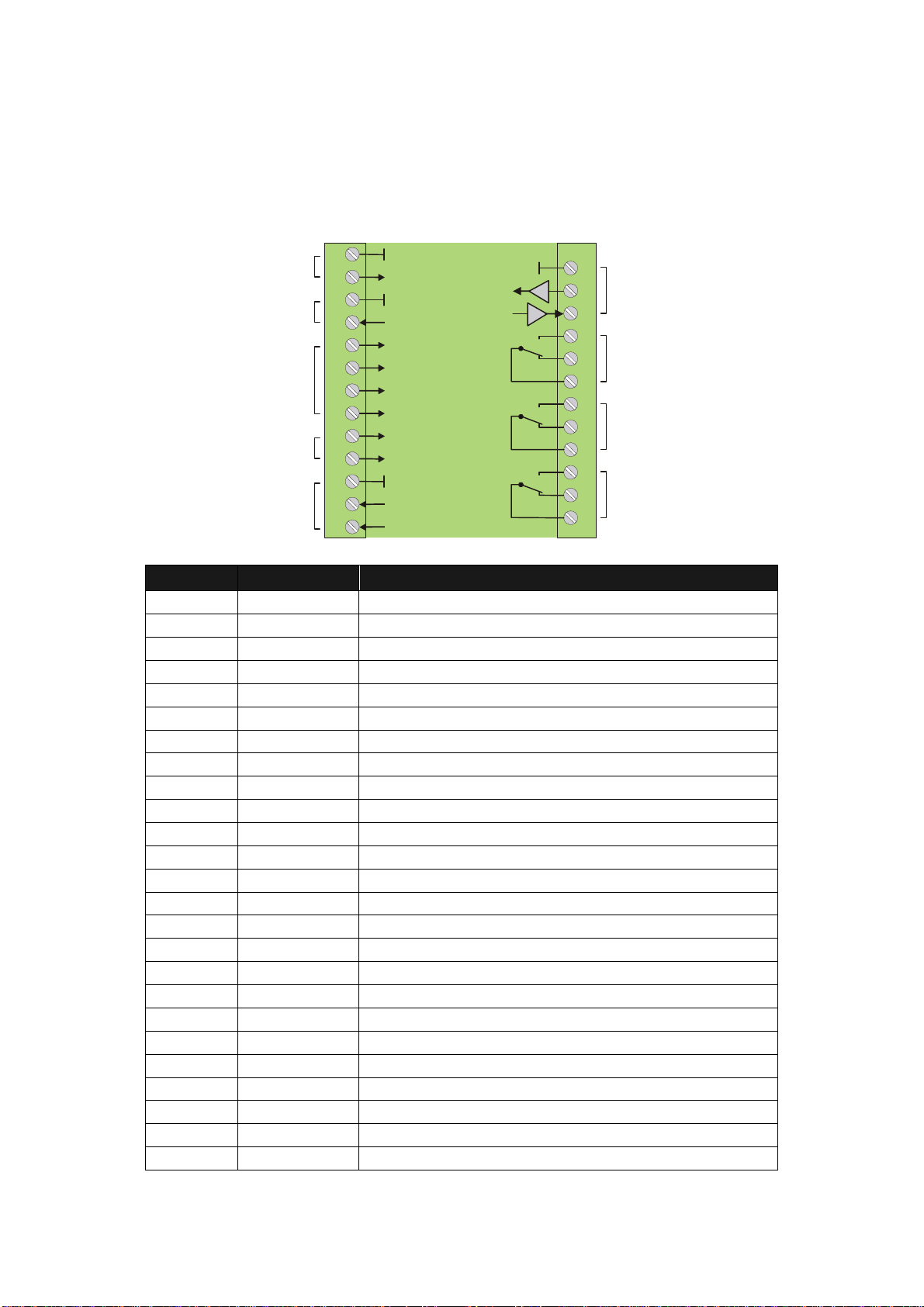

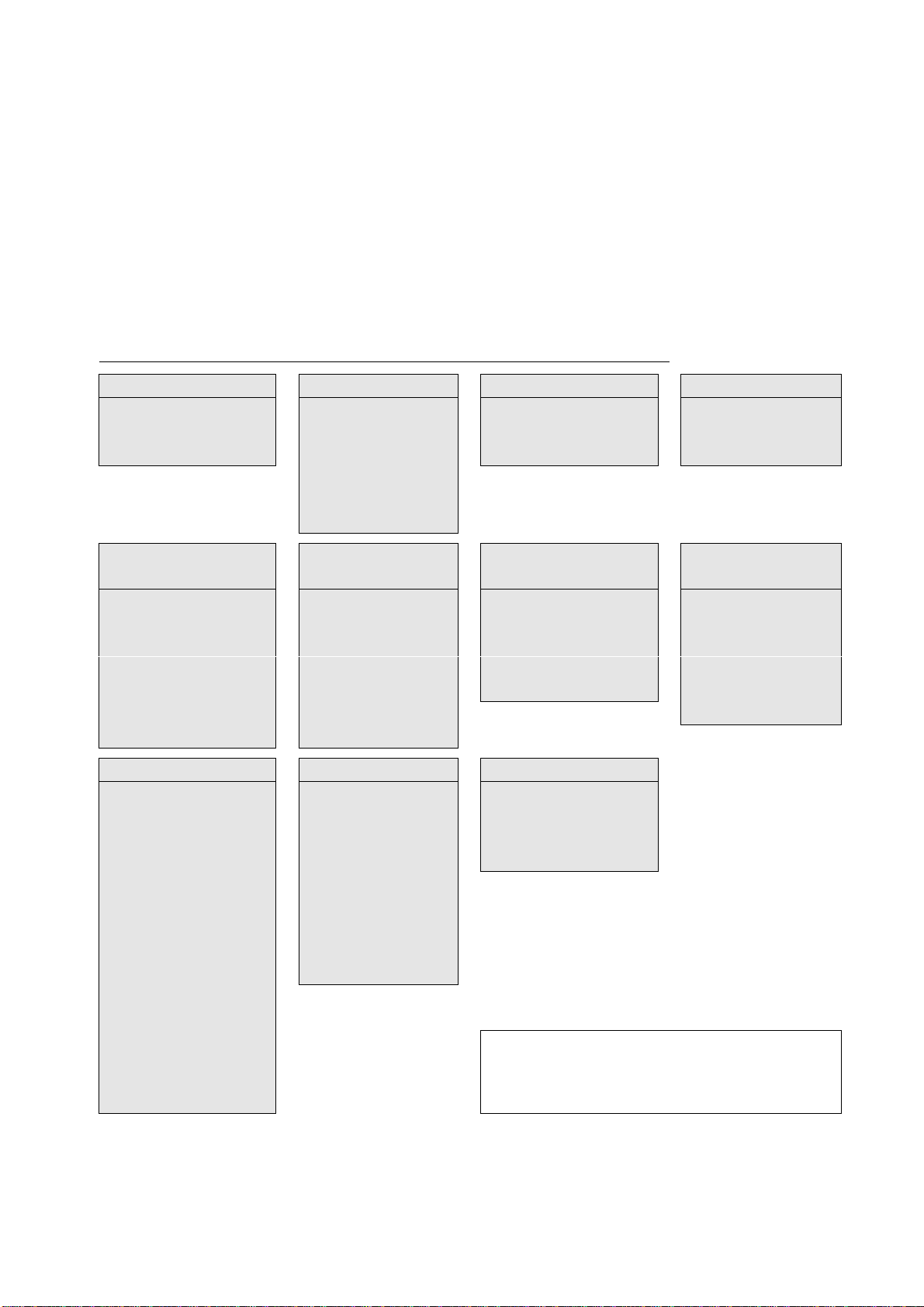

3. Electrical Connections

DZ270

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

GND (-)

GND

GND

GND

RxD

TxD

K1

K2

K3

+Power input

+5,2V

SIN+

SIN-

COS+

COS-

0 - 10 V

0/4 - 20 mA

Control 1

Control 2

Aux. Output

+5,2V

Input for

SIN/COS

encoders

Power supply

17 - 30 VDC

Control

inputs

Analogue

output

Serial RS232-

interface

NO

NC

C

NO

NC

C

NO

NC

C

Relay K1

Relay K2

Relay K3

Terminal

Text

Function

01 GND GND, common minus potential

02 Vin Power input, +17 – 30 VDC

03 GND GND, common minus potential

04 +5,2V Aux. output 5,2V / 200 mA

05 SIN+ SIN+ input for encoder

06 SIN- SIN- input for encoder

07 COS+ COS+ input for encoder

08 COS- COS- input for encoder

09 Control 2 Control input with programmable function

10 Control 1 Control input with programmable function

11 GND GND, common minus potential

12 +10V Out Analogue output 0 – 10 V

13 20mA out Analogue output 0 – 20 mA

14 GND GND, common minus potential

15 RXD Serial RS232 interface, data input

16 TXD Serial RS232 interface, data output

17 K1NO Relay 1, normally open contact

18 K1NC Relay 1, normally closed contact

19 K1C Relay 1, common contact

20 K2NO Relay 2, normally open contact

21 K2NC Relay 2, normally closed contact

22 K2C Relay 2, common contact

23 K3NO Relay 3, normally open contact

24 K3NC Relay 3, normally closed contact

25 K3C Relay 3, common contact

DZ27001a_e.doc / Jan-13 Page 6 / 36

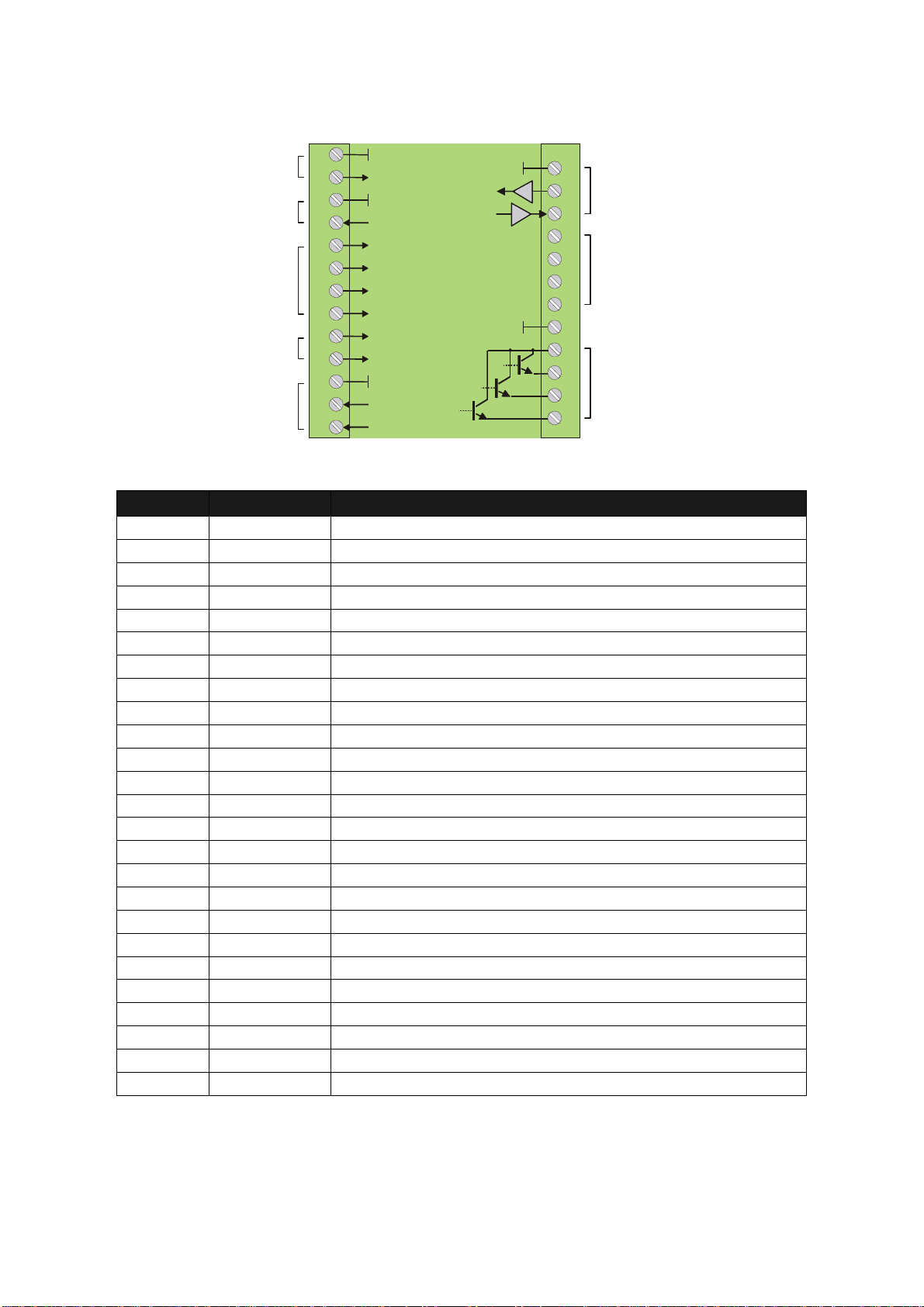

DZ271

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

GND (-)

GND

GND

GND

RxD

TxD

+Power supply

+5,2V

0 - 10 V

0/4 - 20 mA

Control 1

Control 2

Aux. output

+5,2V

Power supply

17 - 30 VDC

Control

inputs

Analogue

output

Serial RS232-

interface

Com + (5-30 V/DC)

GND

NC

K1 out

K2 out

K3 out

SIN+

SIN-

COS+

COS-

Input for

SIN/COS

encoders

Terminal

Text

Function

01 GND GND, common minus potential

02 Vin Power input, +17 – 30 VDC

03 GND GND, common minus potential

04 +5,2V Aux. output 5,2V / 200 mA

05 SIN+ SIN+ input for encoder

06 SIN- SIN- input for encoder

07 COS+ COS+ input for encoder

08 COS- COS- input for encoder

09 Control 2 Control input with programmable function

10 Control 1 Control input with programmable function

11 GND GND, common minus potential

12 +10V Out Analogue output 0 – 10 V

13 20mA out Analogue output 0 – 20 mA

14 GND GND, common minus potential

15 RXD Serial RS232 interface, data input

16 TXD Serial RS232 interface, data output

17 NC Not connected

18 NC Not connected

19 NC Not connected

20 NC Not connected

21 GND GND, common minus potential

22 Com + Common positive input for transistor outputs K1-K3

23 K1 out Output K1, transistor PNP 30 volts, 350 mA

24 K1 out Output K2, transistor PNP 30 volts, 350 mA

25 K1 out Output K3, transistor PNP 30 volts, 350 mA

DZ27001a_e.doc / Jan-13 Page 7 / 36

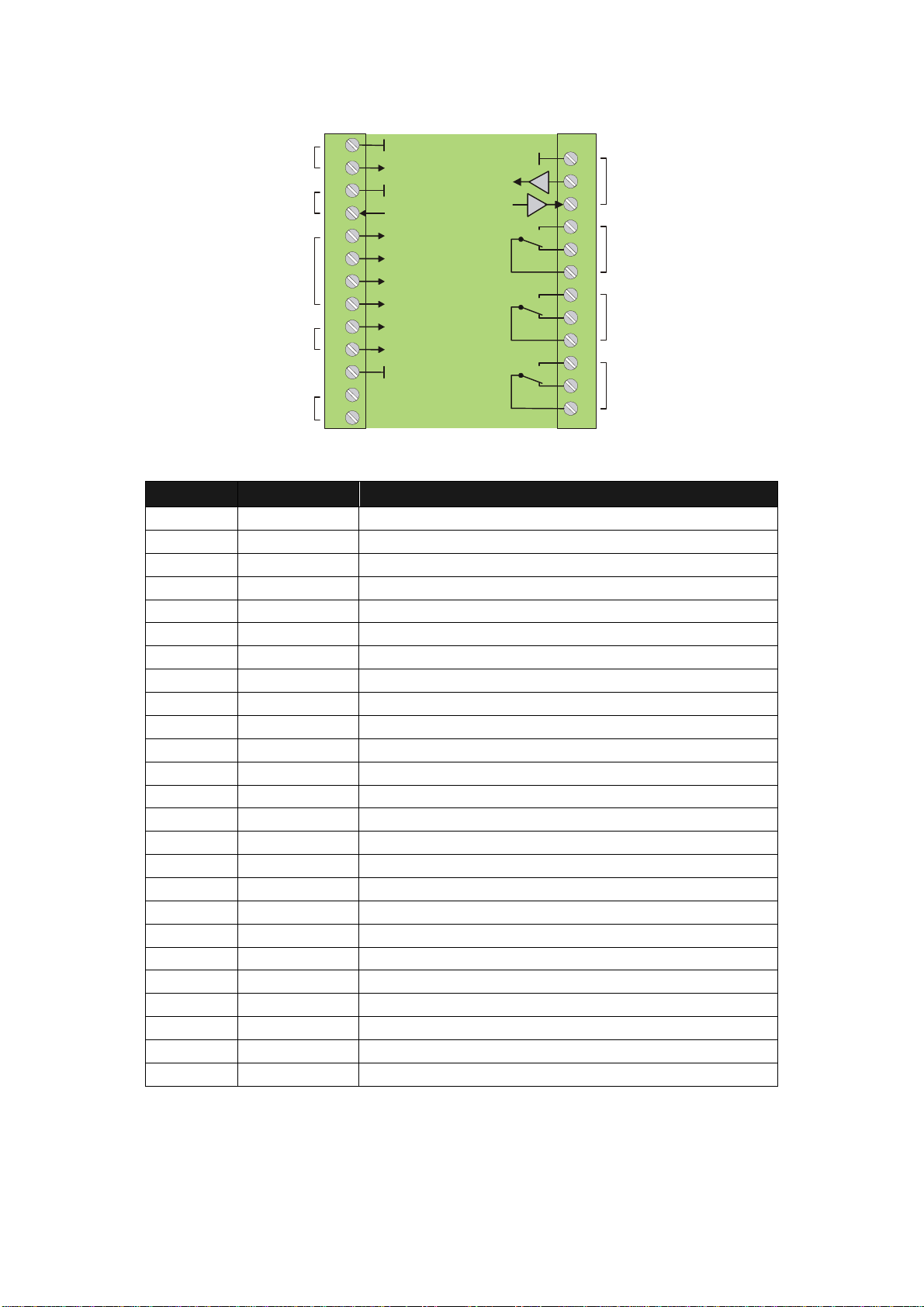

DZ276

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

GND (-)

GND

GND

GND

RxD

TxD

+Power supply

+5,2V

0 - 10 V

0/4 - 20 mA

Control 1

Control 2

Aux. Output

+5,2V

Power supply

17 - 30 VDC

Control

inputs

Analogue

output

Serial RS232-

interface

NC

Input for

SIN/COS

encoders

SIN+

SIN-

COS+

COS-

Terminal

Text

Function

01 GND GND, common minus potential

02 Vin Power input, +17 – 30 VDC

03 GND GND, common minus potential

04 +5,2V Aux. output 5,2V / 200 mA

05 SIN+ SIN+ input for encoder

06 SIN- SIN- input for encoder

07 COS+ COS+ input for encoder

08 COS- COS- input for encoder

09 Control 2 Control input with programmable function

10 Control 1 Control input with programmable function

11 GND GND, common minus potential

12 +10V Out Analogue output 0 – 10 V

13 20mA out Analogue output 0 – 20 mA

14 GND GND, common minus potential

15 RXD Serial RS232 interface, data input

16 TXD Serial RS232 interface, data output

17 NC Not connected

18 NC Not connected

19 NC Not connected

20 NC Not connected

21 NC Not connected

22 NC Not connected

23 NC Not connected

24 NC Not connected

25 NC Not connected

DZ27001a_e.doc / Jan-13 Page 8 / 36

DZ277

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

GND (-)

GND

GND

GND

RxD

TxD

K1

K2

K3

+Power supply

+5,2V

Control 1

Control 2

Aux. output

+5,2V

Power supply

17 - 30 VDC

Control

inputs

NC

Serial RS232-

interface

NO

NC

C

NO

NC

C

NO

NC

C

Relay K1

Relay K2

Relay K3

SIN+

SIN-

COS+

COS-

Input for

SIN/COS

encoders

Terminal

Text

Functi

on

01 GND GND, common minus potential

02 Vin Power input, +17 – 30 VDC

03 GND GND, common minus potential

04 +5,2V Aux. output 5,2V / 200 mA

05 SIN+ SIN+ input for encoder

06 SIN- SIN- input for encoder

07 COS+ COS+ input for encoder

08 COS- COS- input for encoder

09 Control 2 Control input with programmable function

10 Control 1 Control input with programmable function

11 GND GND, common minus potential

12 NC Not connected

13 NC Not connected

14 GND GND, common minus potential

15 RXD Serial RS232 interface, data input

16 TXD Serial RS232 interface, data output

17 K1NO Relay 1, normally open contact

18 K1NC Relay 1, normally closed contact

19 K1C Relay 1, common contact

20 K2NO Relay 2, normally open contact

21 K2NC Relay 2, normally closed contact

22 K2C Relay 2, common contact

23 K3NO Relay 3, normally open contact

24 K3NC Relay 3, normally closed contact

25 K3C Relay 3, common contact

DZ27001a_e.doc / Jan-13 Page 9 / 36

DZ279

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

GND (-)

GND

GND

GND

RxD

TxD

+Power supply

+5,2V

Control 1

Control 2

Aux. output

+5,2V

Power supply

17 - 30 VDC

Control

inputs

NC

Serial Rs232-

interface

Com + (5-30 V/DC)

GND

NC

K1 out

K2 out

K3 out

Input for

SIN/COS

encoders

SIN+

SIN-

COS+

COS-

Terminal

Text

Function

01 GND GND, common minus potential

02 Vin Power input, +17 – 30 VDC

03 GND GND, common minus potential

04 +5,2V Aux. output 5,2V / 200 mA

05 SIN+ SIN+ input for encoder

06 SIN- SIN- input for encoder

07 COS+ COS+ input for encoder

08 COS- COS- input for encoder

09 Control 2 Control input with programmable function

10 Control 1 Control input with programmable function

11 GND GND, common minus potential

12 NC Not connected

13 NC Not connected

14 GND GND, common minus potential

15 RXD Serial RS232 interface, data input

16 TXD Serial RS232 interface, data output

17 NC Not connected

18 NC Not connected

19 NC Not connected

20 NC Not connected

21 GND GND, common minus potential

22 Com + Common positive input for transistor outputs K1-K3

23 K1 out Output K1, transistor PNP 30 volts, 350 mA

24 K1 out Output K2, transistor PNP 30 volts, 350 mA

25 K1 out Output K3, transistor PNP 30 volts, 350 mA

DZ27001a_e.doc / Jan-13 Page 10 / 36

3.1. Power Supply

The units require a DC supply from 17 to 30 volts which must be applied to terminals 1 and 2.

Depending on the input voltage level and internal states, the power consumption may vary and

lies in a range of about 70 mA with a 24 volts input (plus encoder currents taken from the

auxiliary voltage output).

3.2. Auxiliary Output for Encoder Supply

Terminals 4 and 3 provide a +5.2 VDC / 200 mA auxiliary output for supply of encoders and

sensors.

3.3. Inputs for SinCos Encoders and Sensors

The encoder shall be connected at the screw-type terminal 5-8 of the device. Only encoders

with differential sine-cosine signals of 1 Vpp can be used (0.8 Vpp - 1.2 Vpp). At any time the

signals sin+/sin- and cos+/cos- must be available.

Pins 3 (GND) and 4 (+5,2 V) of the screw-type terminal provide an auxiliary power output for the

encoder supply.

3.4. Control Inputs

Two programmable control inputs allow the assignment of functions like remote start-up-delay,

reset of relay lock, hardware interlock of the keypad and similar.

Both inputs provide PNP characteristics and require HTL level. Also it is possible to set the

control function to "active LOW" or "active HIGH".

For evaluation of dynamic events the desired "active edge" can be set (rising or falling edge)

DZ27001a_e.doc / Jan-13 Page 11 / 36

3.5. Serial Interface

The serial RS232 interface in general may be used

for easy setup and commissioning of the units (with use of the OS32 operator software)

to change settings and parameters by PC or PLC during the operation

to read out internal states and actual measuring values by PC or PLC

The subsequent drawing shows how to link the monitor with a PC, using the standard

9-pin Sub-D-9 connector

2

3

5

RxD

RxD

TxD

TxD

GND

Screen

PC

DZ 270

DZ 271

DZ 276

DZ 277

DZ 279

15

(Sub-D-9)

16

14

3.6. Relay Outputs K1 – K3 (DZ270 and DZ 277 only)

The units provide three programmable relay outputs (all dry changeover), providing a switching

capability of 30 volts / 2 amps DC or 125 volts / 0.6 amps AC or 230 volts / 0.3 amps AC. Both,

switching characteristics and monitoring function may be programmed for each of the relays

individually.

3.7. Tansistor Outputs K1 – K3 (DZ271 and DZ 279 only)

The units provide three outputs with programmable switching characteristics.

K1 – K3 are fast-switching and short-circuit-proof transistor outputs with a switching capability

of 5 – 30 volts / 350 mA each. The switching voltage of the outputs must be applied remotely

to the Com+ input (terminal 22). Both, switching characteristics and monitoring function may be

programmed for each of the outputs individually.

3.8. Scalable Analogue Output (DZ270, DZ271 and DZ 276 only)

The units provide a voltage output with a +/-10 volts range (max. load 2 mA) and a current

output with ranges 0 – 20 mA respectively 4 – 20 mA (load 0 – 270 Ω). Beginning and end of

the desired conversion range can be set by the operator menu. The common potential of both

outputs refers to GND.

The total resolution is 14 bits. A settling time of approx. 200µs. is required. The overall

response time of the analogue outputs primarily depends on the selected Sampling Time

setting. After volatile jumps of the input signal, the analogue outputs may need up to two

Sampling Time cycles (plus 200 µsec.) to stabilize.

DZ27001a_e.doc / Jan-13 Page 12 / 36

4. LCD Display and Keys

The units provide a back-lit LCD displays with 2 lines at 16 characters each, and four keys for

setup and command control.

During the setup procedure the LCD display indicates the menu with all parameter texts and the

set values of the parameters.

During normal operation, the LCD display indicates the following information:

Actual speed value

Input frequency, scaled in user units

+156.5 Hz

I: LH O: COO +47 %

Analogue output (not with DZ267, DZ269)

Actual output level in % of full scale

O: Outputs (not with DZ266)

Actual switching states of relays/transistor outputs

(Rel1, Rel2, Rel3)/(out1, out2, out3)

C = Closed, O = Open

I: Inputs

aktueller logical state of inputs

(Control1, Control2)

L = Low, H = High

The "Display Menu" allows free scaling of the speed measuring values and the speed-related

parameters to any kind of engineering units.

DZ27001a_e.doc / Jan-13 Page 13 / 36

5. Keypad Operation

A summary of all parameters and a detailed description of parameter functions is available

under section 6.

For all operation, the units provide four front keys which subsequently will be named as shown

below:

PROG

UP

DOWN

ENTER

The key functions depend on the actual operating state of the units. Basically we have to

distinguish between Normal Operation and Setup Operation

5.1. Normal Operation

While in normal operation state, the units monitor the speed according to the selected

operational parameters and settings. Each of the front keys provides the command functions as

attached to it upon setup in the "Command Menu"

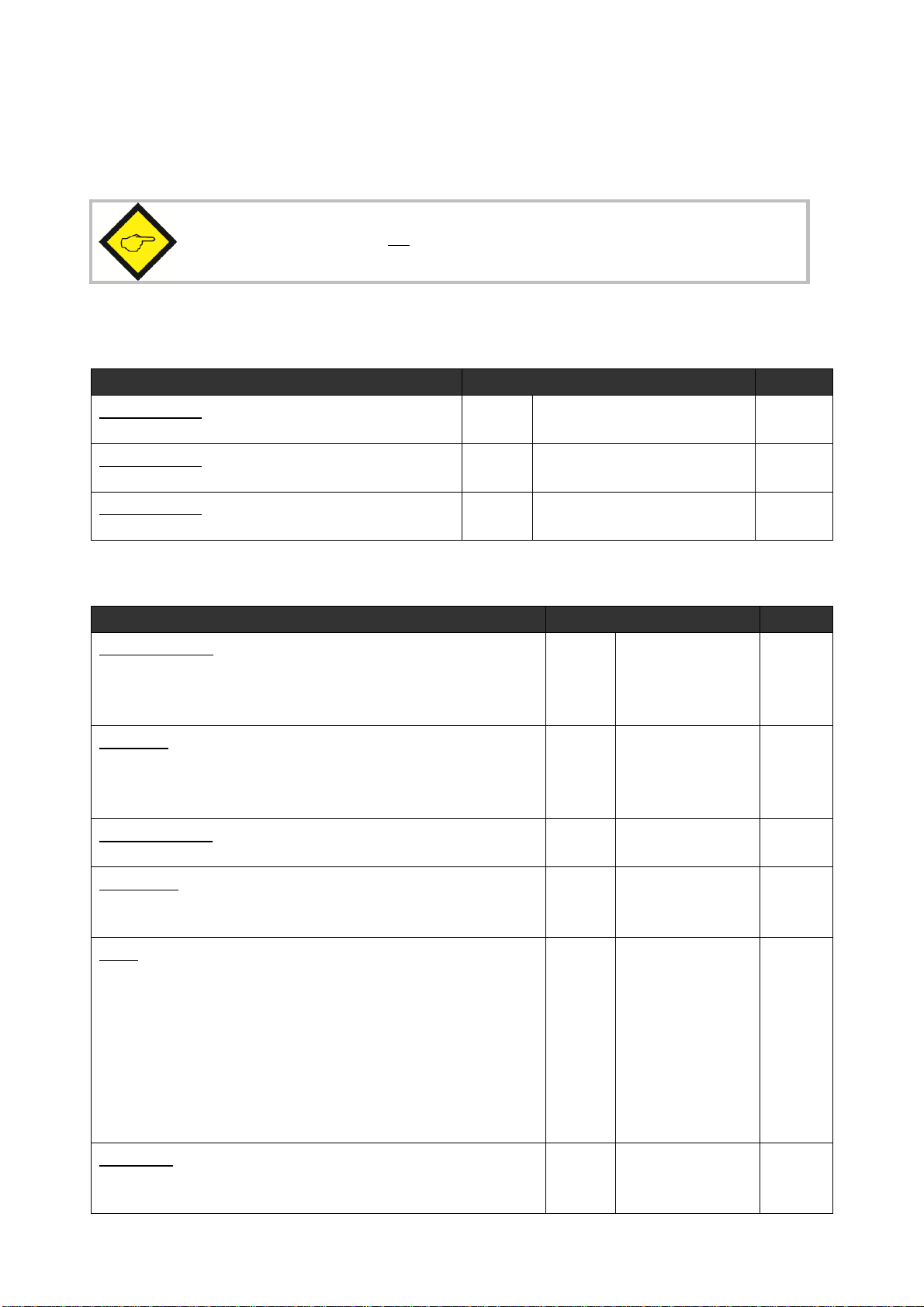

5.2. Keypad Interlock

There is a 3-stage conception to protect the keys against unauthorized changes of the

configuration respectively against activation of commands.

Stage Protected

Range

Protection

by

Key Operations

Change of Parameters Commands

1--- --- permitted permitted

2Menu Password upon

activation of menu

Protection of selectable parts of the menu

via password

permitted

3Keyboard Hardware-Latch 1 interlocked permitted

Hardware Latch 2 All functions interlocked

The "Key Pad" menu allows to define an individual password for each group of parameters. This

function can be used to provide individual access rights to different operators. Upon access to

an interlocked section the unit asks for the corresponding password. If the correct password is

not entered in time, the unit denies access and automatically returns to normal operation.

The hardware latch function can be activated and deactivated by one of the Control Inputs, or

by means of serial access to the corresponding locking register.

Using the Hardware Latch function may accidentally cause a total locking of all

functions, when the Control Inputs characteristics have been set inauspiciously.

In this exceptional case you can release the key functions again by either

a) applying the correct logical state (High or Low) to the inputs

b) or resetting the parameters to their default values (see section 5.6.)

c) or change the parameters being responsible for the locking by PC

P

DZ27001a_e.doc / Jan-13 Page 14 / 36

5.3. General Setup Procedure

To change over from normal operation to the setup state, please keep down the PROG key for

at least 2 seconds. After this the menu appears and you can select one of the menu groups.

Inside each group you can select the desired parameter and edit the setting according to need.

After this you are free to edit more parameters, or to return to normal operation.

The function of the different keys during setup is shown in the table below.

Key

Menu Level

Parameter Level

Setting Level

PROG

Save settings and return

to normal operation

Return to Menu Level Check entry, store result,

then go back to Parameter

Level

UP

Switch over to next

menu

Select next parameter Increment the highlighted

digit or scroll the setting

upwards

DOWN

Go back to previous

menu

Select previous parameter Decrement the highlighted

digit or scroll the setting

downwards

ENTER

Switch over to the

Parameter Level of the

current menu

Switch over to

Setting Level

Shifts the highlighted digit

one position to the left, or

from utmost left to utmost

right

5.4. Changing Parameters on the Setting Level

With signed parameters, the front digit can only be changed between „+“ (positive) and „-„

(negative). The subsequent example explains how to change a parameter from originally 1024

to a new value of 250 000.

The example assumes that you are already on the Setting Level, i.e. you have already selected

the corresponding parameter and read its actual value on the display. Highlighted (blinking)

digits are marked by background color and indicate the cursor position.

DZ27001a_e.doc / Jan-13 Page 15 / 36

No.

Display

Key action

Comment

00

00102

4

The actual value 1024 is displayed, with

the last digit blinking

01

4 x

Change last digit to 0

02

00102

0

Shift cursor to left

03

0010

2

0

2 x

Change highlighted digit to 0

04

0010

0

0

2 x

Shift curser to

left by 2 positions

05

00

1

000

Change highlighted digit to 0

06

00

0

000

Shift cursor to left

07

0

0

0000

5 x

Change highlighted digit to 5

08

0

5

0000

Shift cursor to left

09

0

50000

2 x

Change highlighted digit to 2

10

2

50000

Save new setting and return to

Parameter Level

5.5. Return from the Menu, Time-Out Function

At any time the PROG key changes the Menu by one level backwards or fully back to the normal

operation mode. The menu also switches automatically one level backwards, every time when

for 10 seconds no key has been touched (Time-Out-Function).

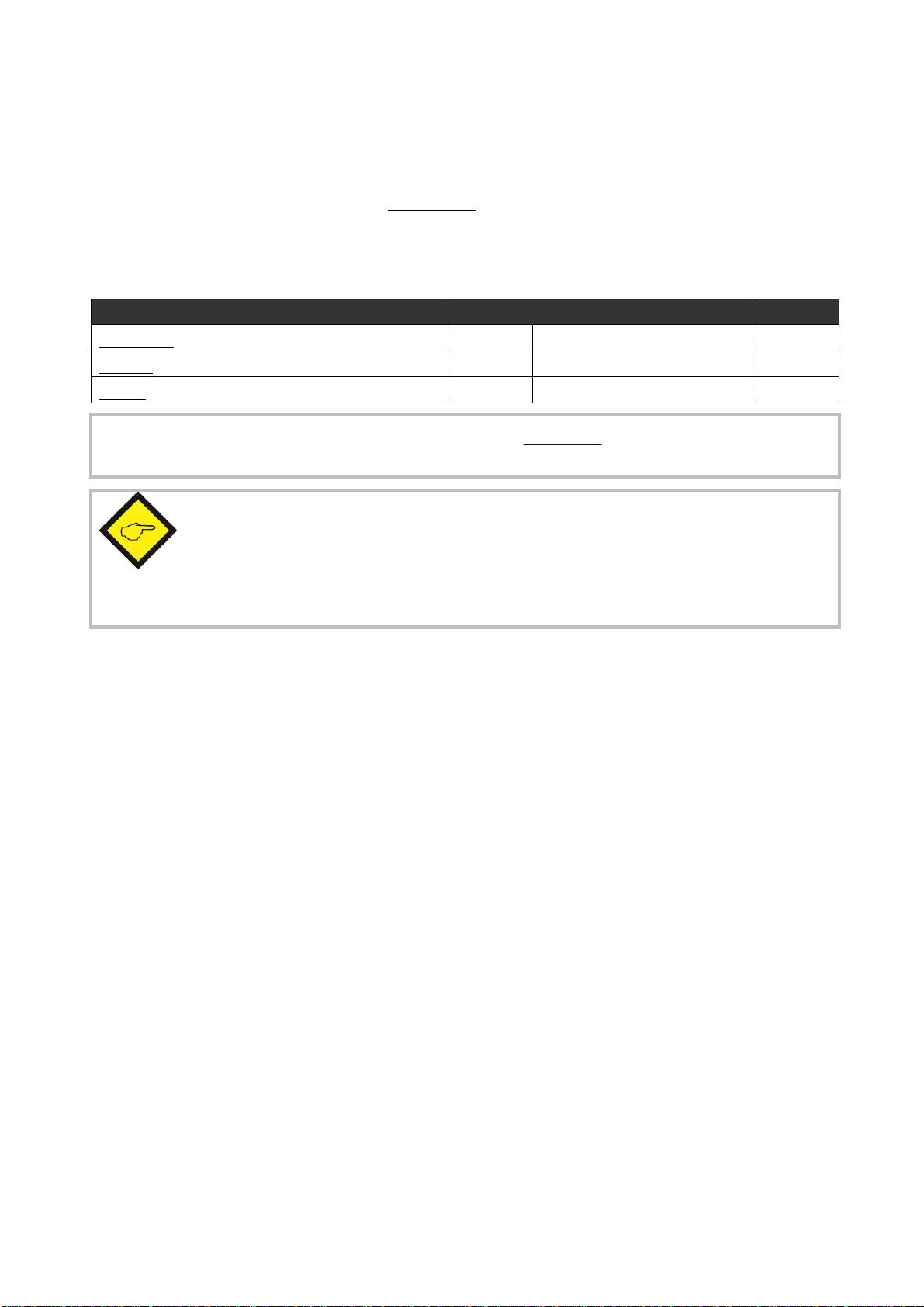

5.6. Reset all Parameters to Factory Default Values

If applicable, the whole set of parameters can be reset to factory default values (e.g. because a

code for the keypad interlocking has been forgotten, or because the unit does no more work

correctly for reasons of bad settings). All default values are indicated in the following

parameter tables.

To execute this Reset procedure, you have to take the following steps:

Power the unit down

Press

and

simultaneously

Switch power on with both keys held down

Where you decide to execute this action, please be aware that all parameter

settings will be lost, and you will have to repeat the whole setup procedure

DZ27001a_e.doc / Jan-13 Page 16 / 36

6. Menu Structure and Parameter Description

All parameters are combined to groups, arranged in several menus. You must only set those

parameters which are really relevant for your individual application.

6.1. Survey of Menus

This section provides an overview of the menus and their assignments to the different functions

of the units. The menu names are printed bold, and associated parameters are arrayed directly

under the menu names.

Menu texts are in English, according to the presentation on the LCD display

Preselect.-Menu*Encoder-Menu Ser.Readout Menu Special-Menu

Preselection 1 Encoder Proper Multiplier Linear Mode**

Preselection 2 Direction Divider Freq. Control

Preselection 3 Sampling Time Offset Input Filter

Wait Time

Filter

Set Value

Key-Pad-Menu Command-Menu

***

Analogue-Menu** Serial-Menu

Protect Menu M01 Key Up Func. Analogue Format Unit Number

Protect Menu M02 Key Down Func. Analogue Start Serial Baud Rate

Protect Menu M03 Key Enter Func. Analogue End Serial Format

… Input 1 Config. Analogue Swing Serial Protocol

Protect Menu M09 Input 1 Func. Analogue Offset Serial Timer

Protect Menu M10 Input 2 Config. Register Code

Protect Menu M11 Input 2 Func.

Switching-Menu*Linear.-Menu** Display-Menu

Pulse Time 1 P1(x) Up-Date-Time

Pulse Time 2 P1(y) Display Mode

Pulse Time 3 P2(x) Encoder Factor

Hysteresis 1 P2(y) Multiplier

Hysteresis 2 ..

Hysteresis 3 P14(x)

Preselect Mode 1 P14(y)

Preselect Mode 2 P15(x)

Preselect Mode 3 P15(y)

Output Polarity

Start up Mode

Start up Relay (*) not relevant with DZ 276

(**) not relevant with DZ 277, DZ 279

(***) partially inactive with DZ 276

Lock Relay

Standstill Time

DZ27001a_e.doc / Jan-13 Page 17 / 36

6.2. Parameter Descriptions

6.2.1. Preselections

Preselection parameters are not relevant for model DZ276

These parameters assign the desired switching points to the relays/outputs. The preselections

use the same engineering units as the display of the actual speed (see Display-Menu).

Preselection Menu

Code

Setting Range

Default

Preselection1

Switching point of relay 1/ out 1 (engineering units)

„00“ -1 000 000.0 ... +1 000 000.0 100.0

Preselection2

Switching point of relay 2/ out 2 (engineering units)

„01“ -1 000 000.0 ... +1 000 000.0 200.0

Preselection3

Switching point of relay 3/ out 3 (engineering units)

„02“ -1 000 000.0 ... +1 000 000.0 300.0

6.2.2. Definitions for the Encoder or Speed Sensor

Encoder

-

Menu

Code

Setting Range

Default

Encoder Proper

Encoder properties

„A0“ 0..1 0

0

1

SIN+/SIN-/COS+/COS-

SIN+/SIN-

Direction

Definition of the direction of rotation with quadrature encoders

„A1“ 0, 1 0

0 forward when A leads B

1 forward when B leads A

Sampling Time

Internal time base for sampling of the input frequency (sec.)

„A2“ 0.001..9.999 0.001

Wait Time

Time to wait before unit detects zero speed (sec.)

Impulse distances greater than this time will be takes as zero

„A3“ 0.01..9.99 1.00

Filter

Digital filter for smoothing of unstable frequencies

„A4“ 0..7 0

0 Filter off

(very fast response to frequency changes)

1Τ(63%) = 1,9 msec. with Sampling Time = 1msec.

2Τ(63%) = 3,8 msec. with Sampling Time = 1msec.

etc.

7Τ(63%) = 122 msec. with Sampling Time = 1msec.

(very slow response to frequency changes)

Set Value

Fixed frequency set value for encoder simulation (Hz)

(see also "Command"-Menu)

„A5“ -1 000 000.0 ...

+1 000 000.0

0

DZ27001a_e.doc / Jan-13 Page 18 / 36

6.2.3. Serial Readout Menu

An actual value proportional to the input frequency can be read out via serial link, accessing the

serial readout register (code :8 ) As a Basic Value this register uses the scaling set for the

analogue output, i.e. a range from 0 to 10 000 units corresponding to 0 - 100,00% of the full

scale output (see "Analogue Menu"). This readout can still be rescaled to user-friendly

engineering units, using the following parameters:

Serial Readout Menu

Code

Setting Range

Default

Multiplier

„A8“ -99999…99999 10000

Divider

„A9“ 0…99999 0

Offset

(absolute term) „B0“ -99999999…99999999 0

Readout (:8) = Basic Value x

Multiplier

Divider

+ Offset

The definition of the "Basic Value" occurs in the "Analogue Menu" and is also

available for the DZ277 units without analogue output

the ratio Multiplier / Divider must never be greater than 15 000

Setting "Divider" to zero will skip the rescaling procedure, resulting in a shorter

response time with all functions of the unit

More details about serial communication can be found in the appendix.

DZ27001a_e.doc / Jan-13 Page 19 / 36

6.2.4. Special-Menu

Special

-

Menu

Code

Setting Range

Default

Linear Mode

Programmable linearization for Basic Value and Analogue Output

„B3“ 0..2 0

0 Linearization off

1 Linearization range 0 – +10V

2 Linearization range -10V … +10V

Freq. Control

Defines behavior and response of the unit to sudden interruptions

of the input frequency.

This parameter must only be changed in very special cases and

under special instruction of an motrona engineer.

Otherwise please use always the default setting "2"!

„B4“ 0..2 2

Input Filter

Digital filter for limitation of the input frequency

„B5“ 0..3 0

0 Filter off, the full range of frequency will be evaluated

1 Filter to cut frequencies higher than 500 kHz

2 Filter to cut frequencies higher than 100 kHz

3 Filter to cut frequencies higher than 10 kHz

Using the Input Filter will cause wrong frequency measurement when you use the unit

with frequencies higher than indicated above.

6.2.5. Key-Pad-Menu

Key

-

Pad

-

Menu

(Passwords for menu groups)

Code

Setting Range

Default

Protect Menu 01 (

Preselect.-Menu

)

„C0“ 0..999999 0

Protect Menu 02 (

Encoder-Menu

)

„C1“

Protect Menu 03 (

Ser.Readout.-Menu

)

„C2“

0 = no interlock

Protect Menu 04 (

Special-Menu

)

a)

„C3“ 6079

Protect Menu 05 (

Key-Pad-Menu

)

„C4“

1

–

999 999 =

Protect Menu 06 (

Command-Menu

)

„C5“

Password for the

Protect Menu 07 (

Analogue-Menu

)

„C6“

corresponding

Protect Menu 08 (

Serial-Menu

)

„C7“

group

Protect Menu 09 (

Switching-Menu

)

„C8“

Protect Menu 10 (

Linear-Menu

)

„C9“

Protect Menu 11 (

Display-Menu

)

„D0“

a) This menu is protected by the password 6079 due to factory setting. After entry of the

password please press the Enter button at least 2 seconds.

DZ27001a_e.doc / Jan-13 Page 20 / 36

6.2.6. Command-Menu

Command

-

Menu

(assignment of functions)

Code

Setting Range

Default

Key Up Func

.

Supplementary command function of the UP key

„D7“ 0..9 0

0 no function

1 Activation of a serial data transmission

2 Force programmed relay/output states / freeze (a)(c)

3 Frequency simulation according to parameter "Set Value"

4 Freeze actual input frequency

5 Remote start-up-delay function (a)

6 Release lock of relay 1 (a)

7 Release lock of relay 2 (a)

8 Release lock of relay 3 (a)

9 Release lock of all relays 1-3 (a)

Key Down Func

.

Supplementary command function of the DOWN key (see UP)

„D8“ 0..9 0

Key Enter Func

.

Supplementary command function of the ENTER key (see UP)

„D9“ 0..9 0

Input 1 Config

.

Switching characteristics of input „Control1“

„E0“ 0..3 0

0 Static low

1 Static High

2 Dynamic, rising edge

3 Dynamic, falling edge

Input 1 Func.

Control function of input „Control1“

„E1“ 0..12 0

0 no function

1 Activation of a serial data transmission

2 Force programmed relay/output states / Freeze (a)(c)

3 Frequency simulation according to parameter "Set Value"

4 Freeze actual input frequency

5 Remote start-up-delay function (a)

6 Release lock of relay 1/transistor output 1 (a)

7 Release lock of relay 2/transistor output 2 (a)

8 Release lock of relay 3/transistor output 3 (a)

9 Release lock of all relays 1-3/output 1-3 (a)

10 Interlock for parameter access via keypad (b)

11 Total keypad interlock (b)

12 Command monitor for remote motion enable signal

Input 2 Config

.

(see Input 1 Config.) „E2“ 0..3 0

Input 2 Func

.

(see Input 1 Func.) „E3“ 0..12 0

(a) these parameters are not relevant for model DZ276.

(b) see section 5.2 (c) see section 8.3 (d) see section 8.4

This manual suits for next models

4

Table of contents

Other Motrona Monitor manuals