8

1.3 Troubleshooting Guide for LCD

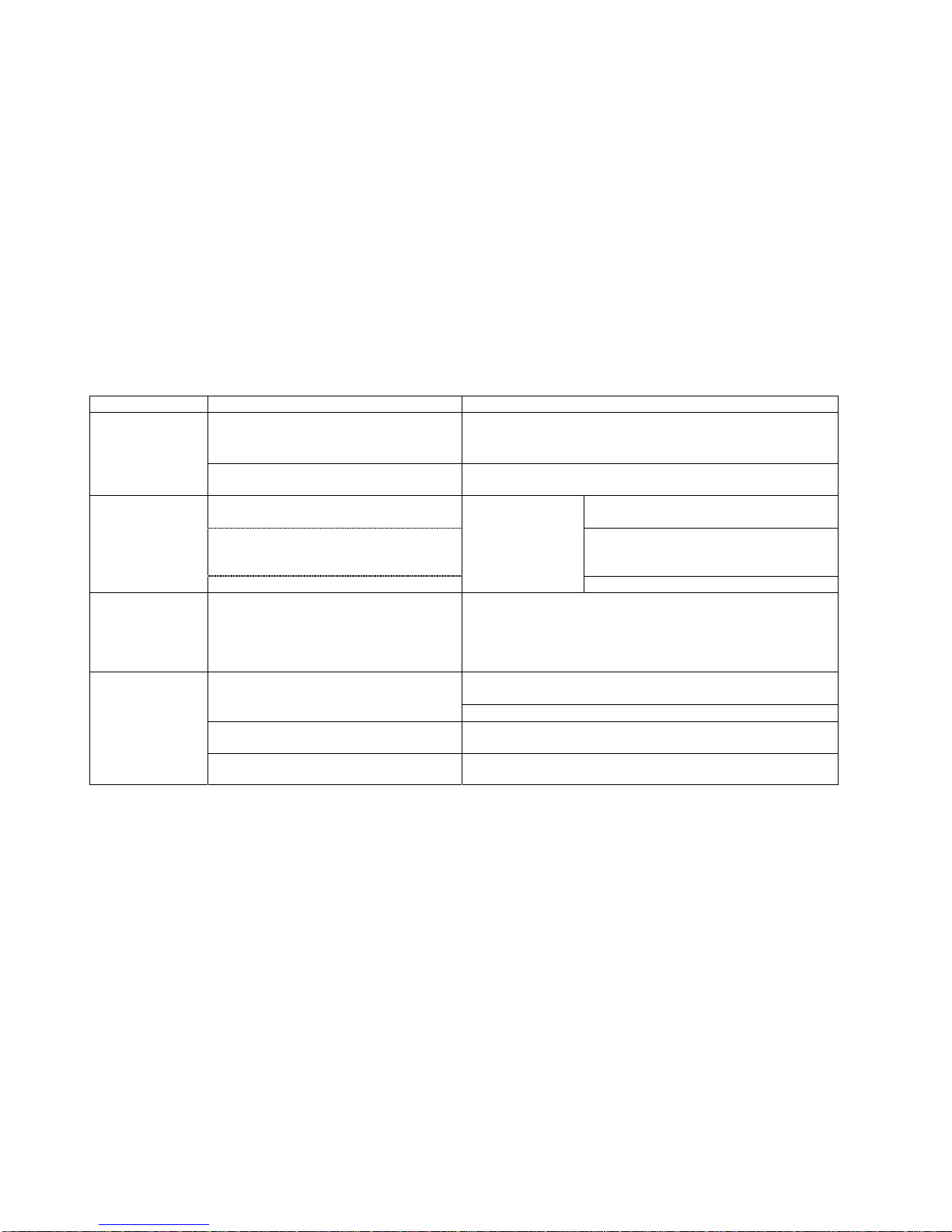

Symptom/Condition PROBABLE CAUSE CORRECTIVE ACTION

Air/cable setting is not

correct Follow the set up procedures in LCD manual.

TV signal source is not

supplied.

- Check if the TV signal source is correctly supplied

to A/D PCB from external source.

- Make sure the cable is properly secure.

- If external TV signal is correct, try to connect the

coaxial cable directly to the internal connector in AD

PCB of Console to check whether the internal

cables are wrong or not.

75 ohm coaxial cable is bad. Replace 75 ohm coaxial cable.

Snow and noise are scattering on LCD screen. Any picture is

not found even though channel-up button or channel-down

button is pressed.

A/D Board is damaged. Replace A/D Board with new one.

LCD screen is uniformly white Internal cable connection is

loose or disconnected.

Check if the connection between LCD screen and

A/D Board is tight. In other word, LVDS cable shown

in picture.

Vertical large white-stripe or Vertical stripe block on LCD

screen Problem with LCD screen Replace LCD screen

When LCD power is turned on by

pressing TV on/off, “VIDEO”, “S-VIDEO”

or “ANALOG” appears temporarily and

then disappears on the left upper corner

of LCD screen.

TV mode is not set-up.

1) Whenever you press Volume down button, words

are displayed in following order on the left upper

corner of LCD screen.

“ANALOG”=>”VIDEO”=>”S-VIDEO”=>”TV”

2) Press the button until “TV” is displayed.

3) As soon as “TV” is displayed, snow and noise will

be scattering on LCD screen or any picture will be

captured.

LCD screen is dark

or black.

When LCD power is turned on by

pressing TV on/off, “VIDEO”, “S-VIDEO”

or “ANALOG” is NOT displayed on the LCD Power Supply has a

problem. Power Supply is

used for supplying 12 VDC

Check if LCD Power supply is normally operated or

LED lamp on Power supply body is turned on.

If LED is off,