Mounting Systems Pitched ProLine User manual

Pitched ProLine

Installation manual

Pitched ProLine-MA-EN-2011

Introduction

Introduction

. Short Description

. About These Instructions

. Warnings

. Safety

Technical Description

. System Overview

. Components

. Technical Data

Important Mounting Information

. Conditions of Use

. Mounting Preparations

. Mounting Aids and Required Tools

. About the Instructions

Planning the Module Area

Installation of Roof Fasteners

. Preparation of the Roof Substructure

. Placing the Roof Fasteners –

Here: Standard Roof Hooks

. Placing the Roof Tiles

Installing the Base Rails

. Placing and Alignment of the Base Rails

. Connection of the Base Rails

. Placing the End Caps

. Telescoping End Pieces (optional)

Installing the Clickstones

Module Installation

. Fastening the Modules on the Outer Side

. Fastening the Modules on the Inner Side

. Fastening Additional Module Rows

Options: Installing Additional Roof Fastener

. Installation of the Heavy Load Roof Hooks

. Installing Adjustable Roof Hooks

. Installation of Plain Tile and Slate Roof Hooks

. Installing Hanger bolts

. Roof connection with hanger bolt

. Installing Standing Seam Clamps

Option: Installation of the CCS-rail

. Placing and Alignment of the CCS-rail

. Connection of the CCS-rail

Option: Cross Rail Installation

3

Installation manual Pitched ProLine

i

1. Introduction

.. Short Description

The Pitched ProLine on-roof system is a robust

mounting system for the installation of PV modules on

pitched roofs.

It consists of aluminium support rails and all necessary

small parts for the fastening of the rails to the roof, the

modules on to the rails as well as for the connection

of the components with each other. Pitched ProLine

allows for both portrait and landscape installation of

the modules.

.. About These Instructions

Content

These instructions describe the mounting of the on-

roof system Pitched ProLine and all system-specific

information for planning, components and safety

warnings.

The first part of the Instructions (chapters –)

demonstrates the complete installation of framed

modules. Thereafter, (chapters –) the mounting

steps for certain specific roof types and material

options are explained.

Applicable Documents

In addition to this document, the document

“Installation Instructions for PV Mounting Systems:

General Part” is part of each product delivery.

This document describes the general applicable

information for Mounting Systems products on

standardisation, safety, transport, maintenance,

disassembly and disposal. Both the present Instructions

and the “Installation Instructions for PV Mounting

Systems: General Part” are an integral part of the

system Pitched ProLine and must be adhered to for

each installation.

It is crucial to carefully read these Instructions as well

as all applicable documents prior to carrying out any

installation, maintenance or disassembly work. You are

provided with the information required for the safe and

complete installation, maintenance and disassembly.

Should you have any questions, please contact

Mounting Systems GmbH.

User Group

Mounting Systems GmbH’s installation instructions are

intended for the following persons (user group):

• Skilled personnel

• Instructed personnel

Skilled personnel

Skilled personnel are individuals who, on the basis

of their professional training, are able to execute

installation, maintenance, and disassembly work

appropriately.

Instructed personnel

Instructed personnel are individuals who have been

instructed and taught appropriately regarding the

assigned tasks and the possible risks in the event of

improper conduct. An instructed individual must have

received instructions regarding the required safety

policies, precautions, relevant regulations, accident

prevention regulations, as well as operating conditions

and must have demonstrated his/her competence.

The implemented work must be approved by skilled

personnel.

Orientation Guide

The following visual aids will make installation easier.

Piktograms:

This symbol indicates important information

and useful tips.

This symbol indicates tips and tricks to make

processes easier.

Installation manual Pitched ProLine

1.3. Warnings

The warnings used in these Mounting Instructions

indicate safety-related information. They include:

• Warning symbols (pictograms)

• Signal words for the identification of the hazard level

• Information about the type and source of the hazard

• Information about potential consequences in case of

the hazard being disregarded

• Measures for the prevention of hazards and the

prevention of injuries or damage to property.

The signal words of the warnings respectively indicate

one of the following hazard levels:

1.4 Safety

All generally applicable safety regulations for products

of Mounting System GmbH can be viewed in the

document “Installation Instructions for PV mounting

Systems: General Part”. Please read this document

carefully and adhere to the described points - only use

the system for its intended purpose, comply with the

obligations of the building proprietor and follow both

the general and specific safety instructions.

In addition, please observe the specific safety

instructions which precede the process steps in the

present product-specific Mounting Instructions.

Indicates a great and extraordinary

danger, which may result in death

or serious injury if ignored.

Indicates a potentially dangerous

situation, which may result in

serious or medium injury or

damage to the property.

Indicates a potentially dangerous

situation, which may result in

minor injuries or damage to the

property if ignored.

Indicates potential danger,

which can result in damage

to the property.

WARNING

CAUTION

ATTENTION

DANGER

5

Installation manual Pitched ProLine

2. Technical Description

2.1 System Overview

In the following, the most important system parts are

described.

The design of the individual system components can vary,

or additional components may be required, depending on:

• Type of roof (substructure and roof cladding)

• Type of module

• Number of modules and configuration

• Local conditions

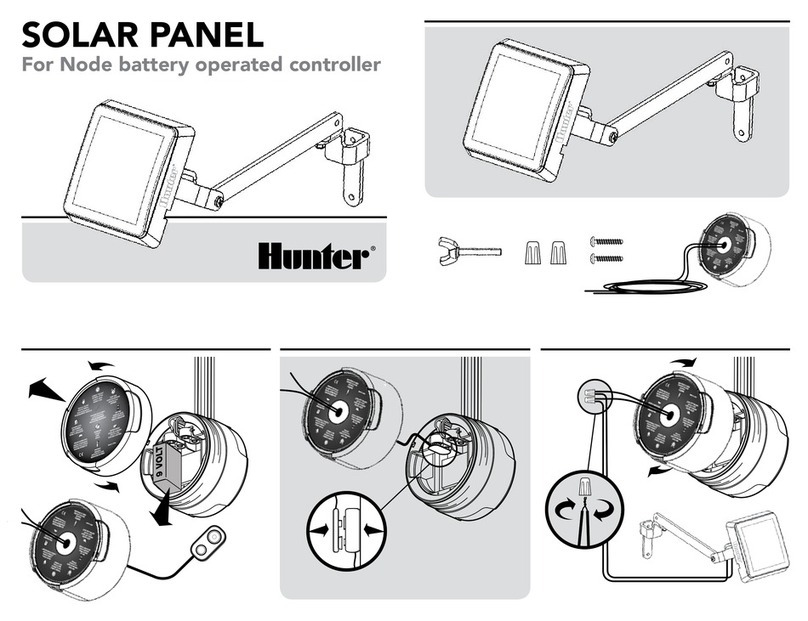

Image 2.1-1 Portrait Installation

Pitched ProLine Components:

a Roof hook

b Base rail

c Connector

d Telescoping end piece (optional)

e Module clamp

f Module end clamp

f

a

b

e

c d

Installation manual Pitched ProLine

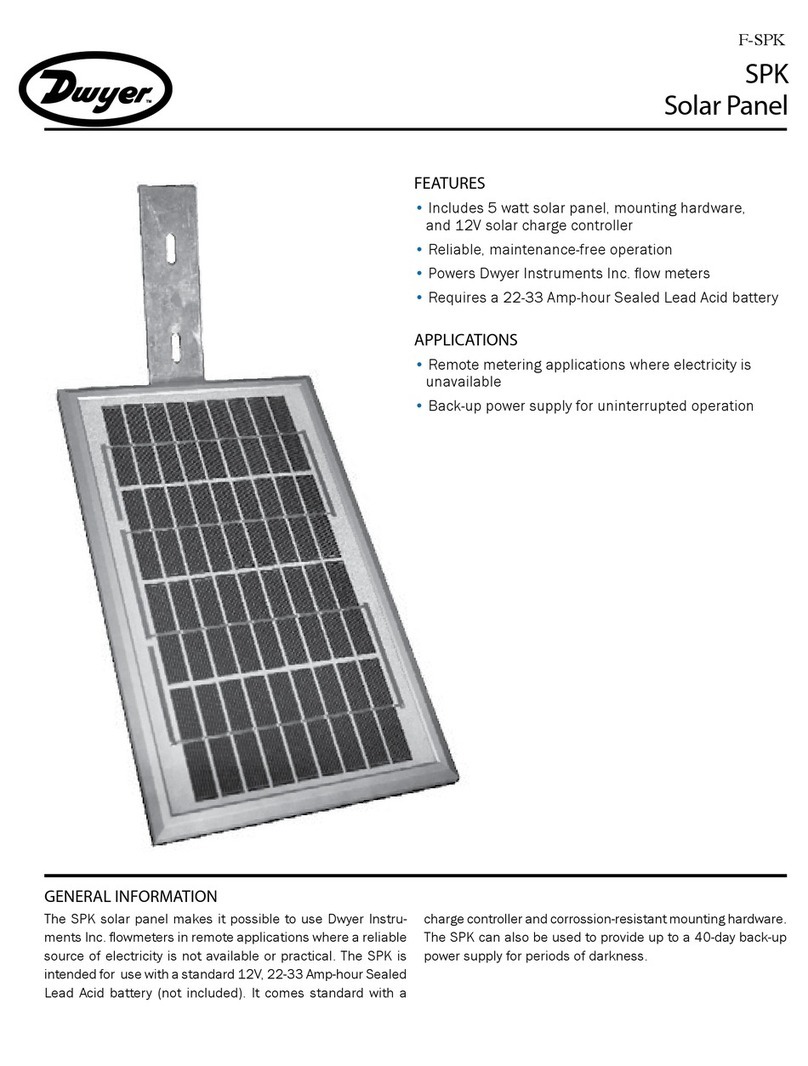

2.2 Components

In the following all mounting system parts of the Pitched ProLine are shown, which can be included in the scope of the

delivery. The exact scope of the delivery and the number of individual components depends on your order.

2.2-1 Base rail (BR), options:

• BR 4/35 in various lengths

• BR 6/40 in various lengths

• BR 10/48 in various lengths

• 0.6 m pieces in black

(respectively for BR 4/35 and BR 6/40)

• BR 4/35 CCS

2.2-2 Connector, options:

• Internal connectors (respectively for BR)

• External connectors (respectively for BR)

• Connector CCS

2.2-3 Telescoping end-piece (optional), options:

• For BR 4/35 and BR 6/40

• Either with mill finished or black end piece

2.2-4 Module end clamp, options:

• For dierent module frame heights

• Mill finished or black

2.2-5 Module clamp, options:

• For dierent spans of module frame heights

• Mill finished or black

2.2-6 Roof fastener, options:

• Roof hooks in various designs

(example shown here: standard roof hook)

• Hanger bolts in various designs

(example shown here: hanger bolt with rubber seal)

• Sheet-metal clamps in various designs

(example shown here: Kalzip clamp)

2.2-7 Fastening materials for roof hooks in various

designs depending on type of roof hook

2.2-8

Small parts for connecting the roof fastener to the

base rail, options:

• L-bracket + small parts (required for some roof

hooks, hanger bolts and sheet-metal clamps)

• T-head bolt and serrated lock nut (supplied loose)

2.2-9 Cross rail connector

2.2-10 End caps (optional), options:

• For BR 4/35, BR 6/40 and BR 10/48

• Grey or black

2.2-1

2.2-2

2.2-3

2.2-9 2.2-10

2.2-4 2.2-5

2.2-6

2.2-7

2.2-8

7

Installation manual Pitched ProLine

2.3 Technical Data

Application Pitched roof – on-roof

Roof cladding Suitable for most types of roof cladding

Roof slope Up to 60° 1

Building height Up to 20 m 1

PV modules Framed, unframed

Module orientation Portrait, Landscape

Size of module array Any size possible 2

Position of the module array No special requirements

Distance between roof

fixing points

Up to 2m 1

Standards Eurocode 1 – Actions on structures

Eurocode 9 – Design of aluminium structures

Supporting profiles Extruded Aluminium (EN AW 6063 T66)

Hooks, small parts Stainless steel (V2A)

Colour Aluminium: plate finish; on request:

Visible components available in black

Warranty 10 Years 3

1

Dierent maximum values may apply, depending on site, building, choice of roof fixations and module type.

Using the Pitched ProLine calculation tool, you can have the exact values for your specific project calculated quickly and easily.

2 Due to thermal expansion of the material, we recommend an interruption of the array after 12 m.

3 Please find the exact terms in the Mounting Systems GmbH warranty document.

Installation manual Pitched ProLine

3. Important Installation Information

. Conditions of Use

The Pitched ProLine on-roof system is designed

with dierent rail and on-roof fastener variations in

accordance with Eurocode -DIN EN -- for various

maximum loads. The suitability of the material must

therefore be verified for each system, e.g. by means of the

Pitched ProLine configuration tool. Please also observe

the constraints, listed in chapter . “Technical Data”.

. Mounting Preparations

Mounting Systems GmbH recommends you inquire about

the local conditions before ordering the Pitched ProLine.

In particular, acquaint yourself with:

• The roof structure,

• Dimensions, material, quality and distance of the

rafter purlins

• the rafter purlins distance with any irregularities

• Type, quality and fastening method of the roof tiles/

roofing

. Mounting Aids and Required Tools

For the installation of the mounting system, you will

require the following tools:

• Allen key/hexagon socket drill bit, mm and mm

• Socket key/socket key attachment size and size

• Cordless screwdriver/electric drill with attachment for

fastening the wood screws; varying depending on the

roof hooks selected:

• Cross recess (for chipboard screws)

AW (for x wood screws)

• Socket key attachment size

(for x wood screws)

• Socket key attachment size

(for Mx hanger bolts)

• Socket key attachment size

(for Mx hanger bolts)

• Angle grinder with

- Metal cutting disc

- Stone disc

• Chalk Line

• Spirit level

• Yard stick/tape measure

. About the Installation Instructions

In the following chapters all steps for the planning

and mounting of the Pitched ProLine are listed in the

correct sequence. Chapters , , and describe the

mounting steps of the modules, chapters – describe

the mounting steps for other material and installation

variations.

Please adhere to the mounting steps listed and be

ensure to follow the safety instructions.

Risk of fatal injury from

damage to roof

Excessive loads can severely

damage the roof.

• Before mounting and installation,

please make sure that the building

and especially the roof cladding

meets the increased structural

requirements for the PV system

and the mounting operation.

Risk of fatal injury from

falling objects

Parts falling from the roof can result

in serious injuries or death.

• Before commencing with the

installation, please ensure that

the material used meets the

structural requirements of the site.

DANGER

DANGER

9

Installation manual Pitched ProLine

4. Planning the Module Area

For installation, the base rails are fastened to the

rafters or purlins (for metal roofs) of the building with

roof fasteners (e.g. roof hooks). The roof fasteners must

be mounted at defined distances, depending on the

distance of the rafters/purlins, the position on the roof

and on the on-site conditions*. The layout is defined

using a configuration tool or project-related structural

analyses.

* Layout required according to local conditions in

accordance with Eurocode -DIN EN --/

Eurocode -DIN EN --.

Risk of fatal injury from

damage to roof

Excessive loads can severely

damage the roof.

• Before mounting and installation,

please make sure that the

building and especially the roof

construction meets the increased

structural requirements resulting

from the PV system and the

assembly operation.

Risk of fatal injury from

falling objects

Parts falling from the roof can result

in serious injuries or death.

• Before any mounting or

installation, please make sure

that the material used is suitable

for the building structure and

meets the structural requirements

applicable on-site.

DANGER

DANGER

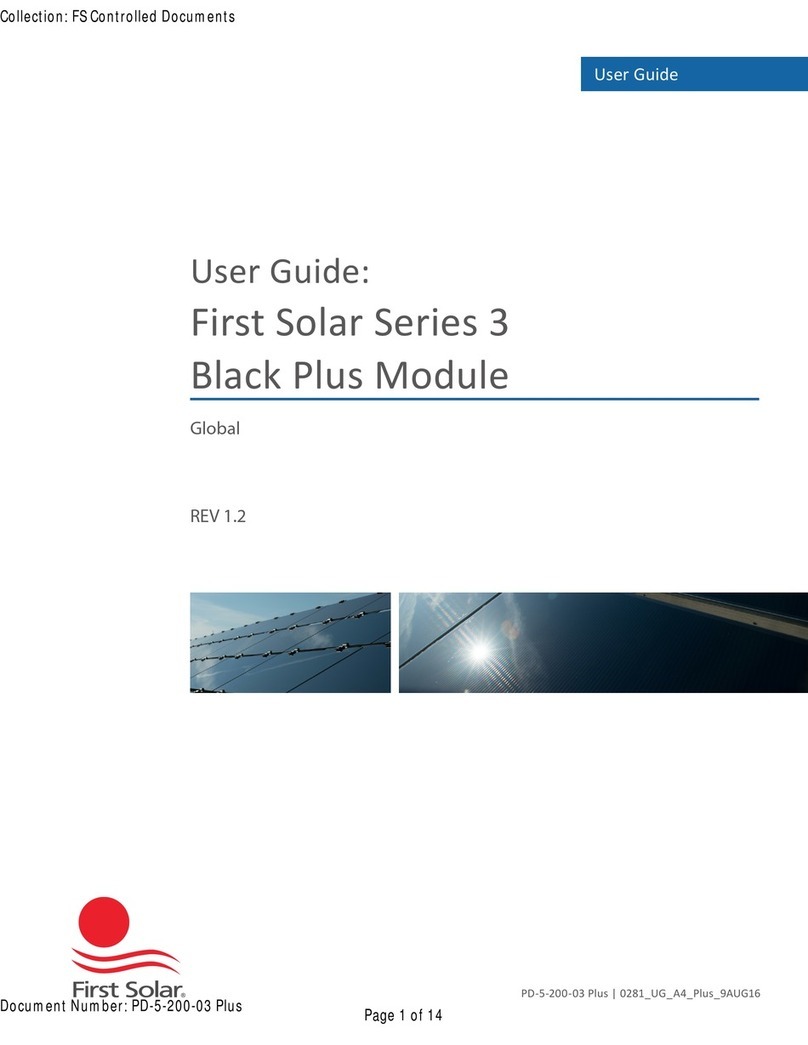

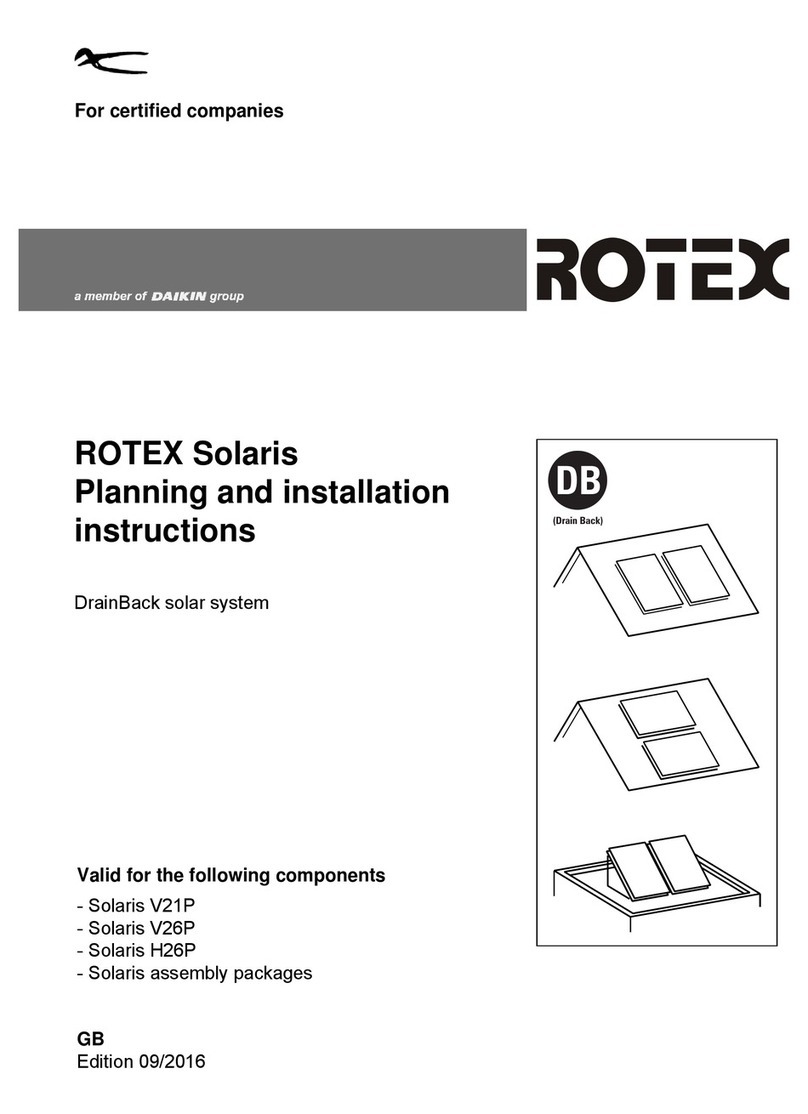

Image – Modul Area

aHeight of the module field: Number of modules

vertically x module length (+ any clearances)

bWidth of the module field: Number of modules

horizontally x (module width + mm) + mm

cDistance of the base rails vertically (taking into

account the tile pattern as well as the number and

positioning of module clamping points approved

by the manufacturer): Approx. quarter points of the

modules = / x module length.

dDistance of the roof hooks horizontally: According to

the project layout, depending on the rafter distance

and the structural calculations*

eDistance between the modules = – mm

* Layout required according to local conditions in

accordance with Eurocode -DIN EN --/

Eurocode -DIN EN --.

e

a

c

d

b

Installation manual Pitched ProLine

Risk of fatal injury due to falling

Falling from the roof can result in

serious injuries or death.

• Please wear the statutory

protective equipment.

• Secure yourself against falling.

• Do not perform any work in strong

winds.

Risk of fatal injury from

falling objects

Parts falling from the roof can result

in serious injuries or death.

• Block off the hazard area on the

ground prior to the mounting work

to prevent falling objects injuring

persons.

• Ensure that no parts can fall off

the roof.

• Please wear the statutory

protective equipment.

• Do not stay in the hazard area.

• Do not perform any work in strong

winds.

• After completion of the

installation, check the racking

system and the modules for a

tight fit.

DANGER

DANGER

11

Installation manual Pitched ProLine

Damage to the building and the PV

system due to incorrect mounting

Incorrect distance between the roof

fasteners can cause damage to the

building and the PV system.

• Select the distance of the roof

fasteners according to the tool

layout and adhere to it.

• Adhere to the potentially different

distance values defined for roof

fasteners to be placed in the

middle of the roof or along the

edge / in the corners of the roof.

CAUTION

5. Installation of Roof Fasteners

The roof fasteners are fixed to the roof structure and

serve as a connector to the base rails. The permissible

distance between the roof fasteners depends on the

structural requirements and must be laid out specifically

for the project, e.g. with the Pitched ProLine configuration

tool. The type of roof fastener must be selected

according to the respective structural load, substructure

and roof cladding. Depending on the roof construction

and the type of roof fastener, the installation process or

the preparation of the substructure can vary or require

additional structural measures. If you have any doubts,

please contact a specialist roofer.

In the following, the installation of a standard roof hook

is described. The mounting steps for other types of roof

fasteners are described in chapter .

.. Preparation of the Roof Substructure

Mounting steps

• Determine the position of the base rails and the

roof fasteners on the roof, taking into account the

system planning, the tile and rafter pattern and the

permissible clamping points of the PV modules used.

• Push up or remove the roof tiles at the appropriate

points.

Image .-

Image .-

xxx

xxx

xxx

xxx

Installation manual Pitched ProLine

Image .-

Image .-

Image .-

Image .-

Image .-

• Prepare the fastening points of the substructure

for professional mounting of the roof fasteners and

ensure suciently load-bearing, wide and level

contact surface.

i

NOTE!

Depending on the roof structure, type of

roof fastener and structural requirements,

various additional structural measures

might be required at the fastening

points. For example, in a counter-batten

construction, the contact surface might

need to be expanded by additional

squared timber screwed to the rafters.

With a frame structure, the roof trusses

might need to be doubled up at the

appropriate positions.

Damage to the building and the PV

system due to incorrect mounting

Incorrectly installed roof hooks can

break away.

• Fasten each roof hook to the

substructure with the stipulated

number of screws.

• Adhere to the permissible

edge distances distance when

positioning the screws.

If necessary, structurally widen the

substructure.

CAUTION

13

Installation manual Pitched ProLine

Image .-

Image .-

Image .-

Image .-

.. Placing the Roof Fasteners - Here: Standard Roof Hook

Mounting steps

• Position the roof hook and, if required, underlay it;

neither the vertical nor the horizontal stay of the roof

hook may touch the underlying roof tile.

• Align the roof hook.

• Fasten the roof hook with wood screws x to the

rafter. Observe the permissible edge distance for

wood drilling.

Image .-

Installation manual Pitched ProLine

Image .-

Image .-

Image .-

.. Placing the Roof Tiles

Mounting steps

• Correctly process the underside of the removed

roof tiles to ensure that the roof tile can be

replaced cleanly and does not stand up due to the

underlying roof hook.

• Reinstall the roof tiles.

• If required, take additional structural measures to

restore rain proofing.

CAUTION

Damage to building from leaking

Incorrectly installed roof hooks and

incorrectly performed restoration of

the rain proofing of the roof cladding

can result in leakages.

• Prior to installation, make sure

to choose a roof fastener variant

that is suitable for the roof and its

requirements.

• Do not install unsuitable roof

fasteners.

• When mounting the roof fastener

adhere precisely to the mounting

instructions.

• Make sure to perform cut-outs

on the tile or any additional

structural measures that might be

required in a professional manner.

If you have any doubts please

contact a specialist roofing

company.

15

Installation manual Pitched ProLine

6. Installing the Base Rails

The base rails serve as module support and are

available in dierent strengths and lengths.

.. Placing and Alignment of the Base Rails

Mounting steps

• Pre-mount the T-head bolt and serrated lock nut to

the roof hook (nut must point in the direction of the

eaves, T-head bolt in the direction of the ridge)

• Lay out the total rail length per rail track (see

chapter ) and perform any rail cut-outs that might

be necessary.

• Distribute the base rails on the roof.

i

NOTE!

The permitted cantilever (overhanging

of the loose rail ends over the last

roof fastener) is limited to 30 cm.

Do not exceed this limit.

NOTE!

Do not fasten all the base rails at

once, but alternate between

installation steps 6.1. and 6.2.

Install the individual base rails

plugged together with a connector.

Image .-

Image .- Image .-

Installation manual Pitched ProLine

Image .-

Image .-

Image .-

Image .-

• Hold the rail against the roof hook, insert the T-head

bolt in the side channel, loosely fasten the screw with

a quarter-turn in the side channel of the base rail,

and loosely tighten the nut.

• Align the base rails by using a chalk line or spirit level.

• Tighten the lock nuts - torque: Nm. Make sure

the T-head bolts are positioned correctly in the rail

channel.

CAUTION

Material damage due to

incorrect mounting

Incorrectly mounted T-head bolts

can slip out.

• When inserting the T-head bolts,

always ensure the correct, vertical

fit of the bolt head in the channel.

• When aligning the rails and during

the final fastening of the T-head

bolts, make sure that the head

of the bolt does not slip into an

incorrect position.

• Adhere to the specified torque of

20 Nm.

17

Installation manual Pitched ProLine

.. Connection of the Base Rails

Rail connectors are provided for the linking of the

individual base rails. There are two dierent versions of

connectors available for each rail thickness; an interior

connector and an exterior connector.

Mounting steps - interior connector

• Insert the rail connector into the first base rail until the

stop.

• Slide the next base rail onto the placed rail connector

until the stop.

Mounting steps - exterior connector

• Slide the connector halfway into the side channel on

the back of the base rail.

• Push the second base rail to the stop on the

connector.

• Tighten both bolts manually, thus completing the

connection. (torque Nm).

Image .. –

Image .. –

Image .. –

Image .. –

Image .. –

Image .. –

i

NOTE!

Connected rails should not exceed a

length of 12 m. Thereafter, an expansion

joint (approx. 5 cm) must be considered.

Do not install modules over expansion

joints. The total rail length required

depends on the width of the module field.

NOTE!

For this connection type, the base rails

can be pre-assembled on the ground.

This may facilitate transport onto and

placing on the roof.

Installation manual Pitched ProLine

Image .. –

Image .. –

.. Placing the End Caps

The end caps are optional components and only have

an optical function.

Mounting steps

• From the outside, push the end caps onto the ends

of the base rails.

19

Installation manual Pitched ProLine

Mounting steps

• Do not finish the base rail row with a pre-cut base

rail but with the telescoping end piece.

• Slide the telescoping end piece into the side

channel on the back of the base rail.

Image .-

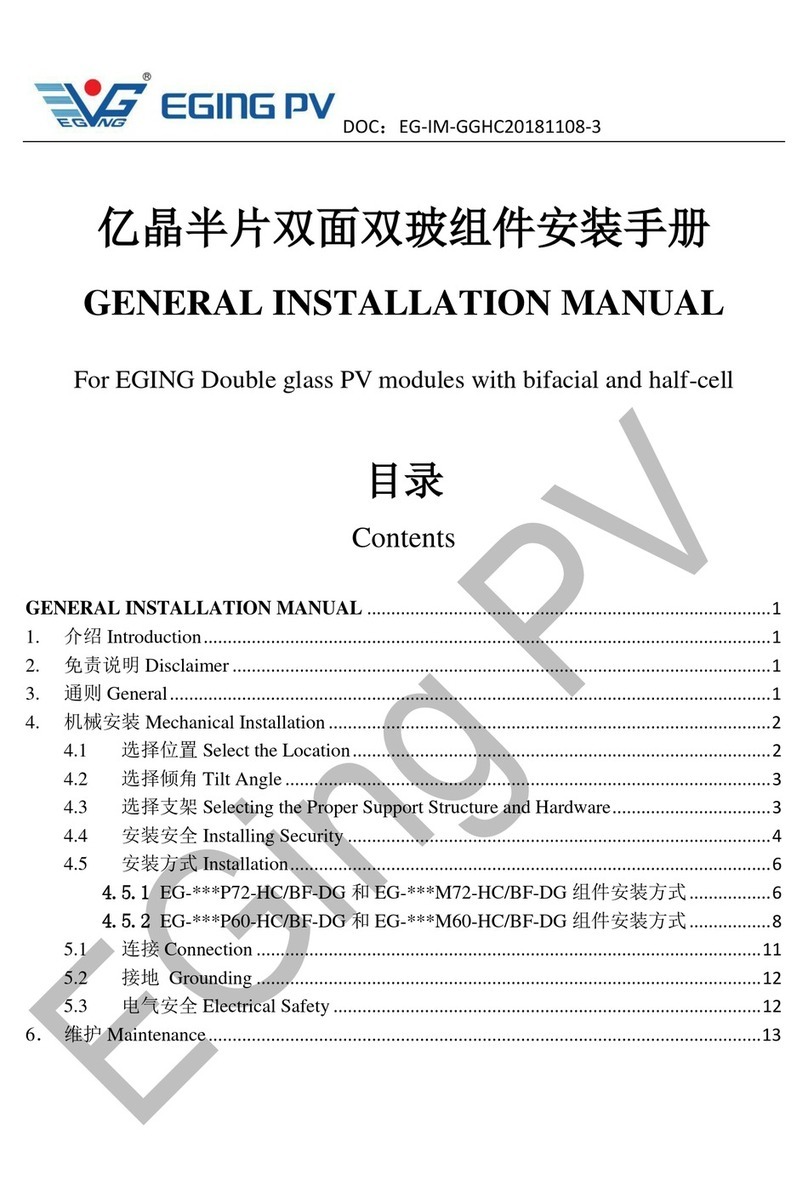

aConnector piece for variable insertion into the base

rail

bBolt and square nut for fastening to the base rail

c Loose base rail section for connection to a roof

fastener (if required)

dPermanently mounted base rail section to take the

module end clamp.

Image .-

Image .-

mm -

mm

c

a

d

c

b

a

d

.. Using Telescoping End Pieces (Optional)

The telescoping end pieces allow for the cut-out-free

setting of the base rail length, precisely to the

millimetre. They are placed on the right side of each

continuous base rail row. You can lengthen the base

rail by a maximum of cm. The telescoping end

pieces are supplied pre-assembled including a narrow

base rail section for fastening to the roof fastener (c)

as well as a slightly wider base rail section for

fastening the module end clamp (d).

Installation manual Pitched ProLine

• If required, push the loose base rail section to the

position of the last roof fastener. Adjust the slide-in

to achieve the desired length for the rail row - for a

clean finish, the rail and telescope should protrude

by the width of the module + mm over the

second last module.

• Fasten the telescoping end piece by manually

tightening the bolt at the base rail.

• Mount the last roof fastener and the module as

described above (chapters ..).

Image .-

Image .-

Image .-

Image .-

Image .-

Image .-

Image .-

x + mm

Table of contents

Other Mounting Systems Solar Panel manuals