PISTOL GRIPAIR SCREWDRIVER OPERATION MANUAL

Page | 1 Rev 2.0 (8/16/13)

SPECIFICATIONS

Note: The recommended air pressure: 80~90psi with 5mm (3/16") air hose and 70psi with 6.35mm (1/4") air hose

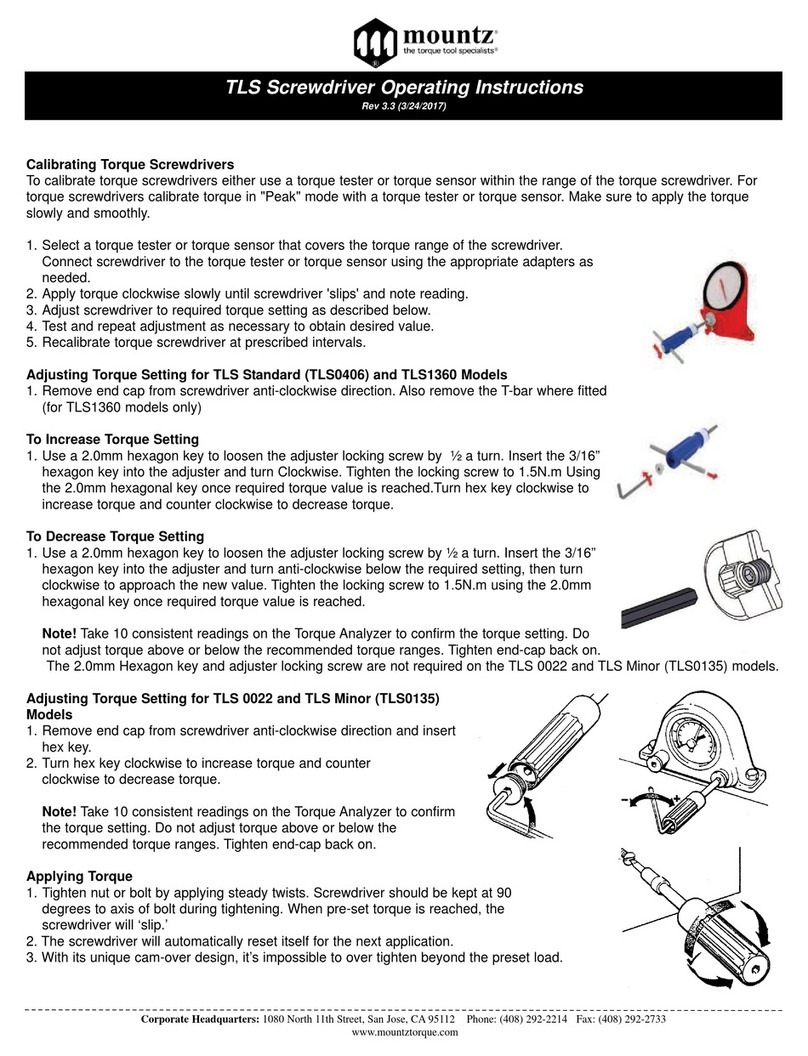

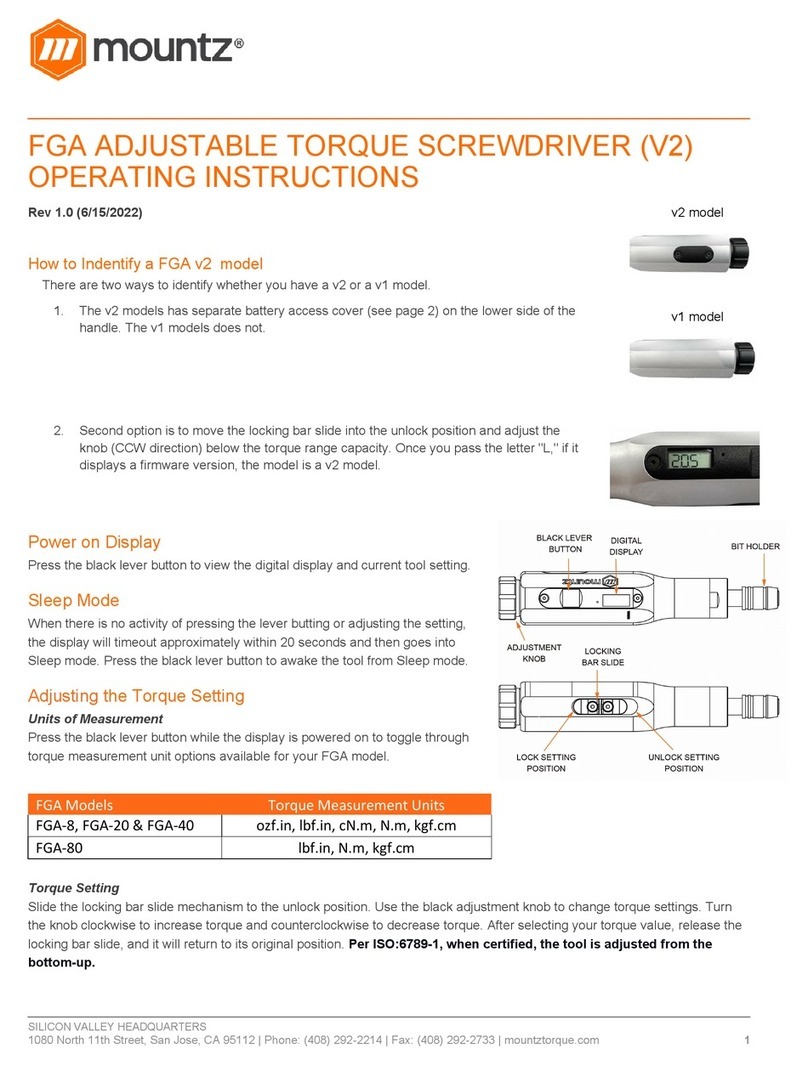

Torque adjustment:

1Unscrew Torque Cover 2Remove Torque Cover 3Rotate torque adjustment 4Rotate torque adjustment

clockwise to increase torque counter-clockwiseto

decreasetorque

OPERATIONS

1.Select a bit. Retract the bit collar. Insert the bit and release the retracted collar. To avoid damage to fasteners,, make

sure the proper bit is suitable for the head of the fastener.

2.Easy torque adjustment. Remove the Torque cover. Rotate the torque adjustment nut to set the torque limit. Turn

clockwise to increase torque and counter clockwise to decrease torque.

Note: Higher Capacity models are supplied with “a "Torque Adjusting Device" used for adjusting the tool for the

upper torque range capacity. Remove Torque Cover. Slide Torque Adjusting Device partially onto Torque Adjustment

nut.

3.Ensure to utilize properly rated hose and fittings to ensure proper airflow and safe operation. Securely attach air

hose

4.Check forward/reverse selector to ensure desired rotation has been selected. Slide torque adjustment switch (Right)

FOR-clockwise, (Left) REV-counterclockwise rotation. Slide torque adjustment switch (Right) FOR-clockwise, (Left)

REV-counterclockwise.

5.Hold tool firmly or ensure the tool is properly secured in a torque arm before starting the fastening process. To start

the tool, engage the fastener and squeeze the lever. The tool will shut-off when the set value is achieved or when

the lever is released. AIR SUPPLY

1.Air tools are adversely affected by moisture. It is strongly recommended to utilize a Filter/Regulator at or near the

workstation to ensure stable air pressure at 80-90 psi for optimal performance and for removal of moisture and

other potential debris which can adversely effect the longevity and performance of an air tool.

2.When using new air hose or air line, it is strongly recommended to first purge the line prior to connecting and

operating your tool.

3.When disconnecting an air line, It is important to stow or store the air line in a manner which will prevent debris

from collecting in couplers or entering the hose or line.

4.Inspect filter/regulators and drain air tanks and/or reservoirs to minimize potential issues related to moisture and

debris.

5.Tools are designed for oil free operation, thus lubrication via the air supply is not required.

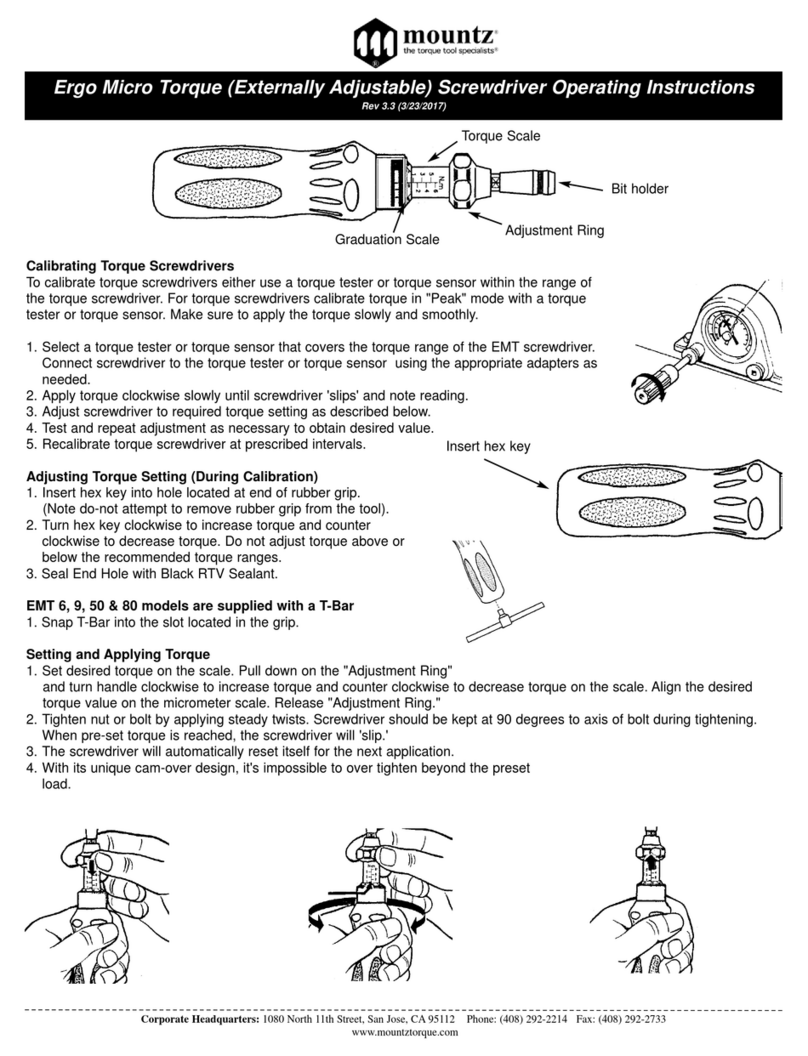

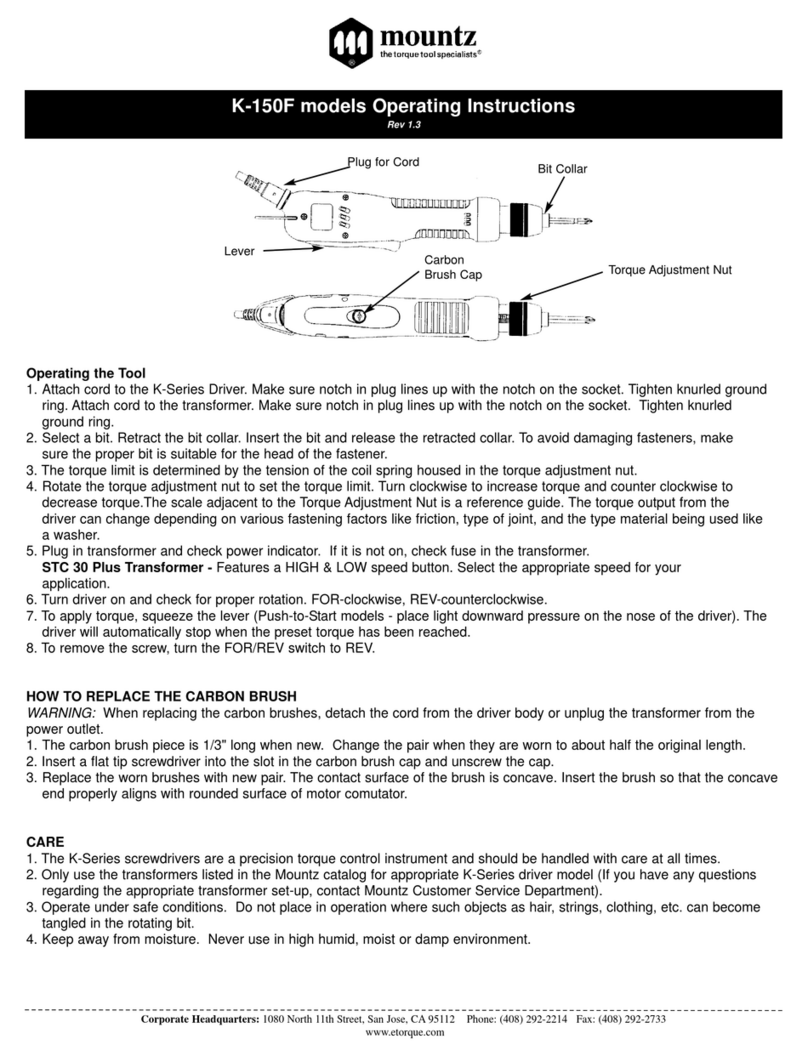

Model

No. Free

Speed Weight

O.A.L

Dia.

Air

Consumption Torque range

(soft joint)

rpm g inch inch l/s lbf-in Nm

XP35P 2,200 690

7.1 1.3 4.7 2.6-17.4 0.3-2.0

XP41P 1,000 690

7.1 1.3 4.7 4.3-30.4 0.5-3.4

XP48P 1,700 1030

8.5 1.5 9.2 6.1-43.4 0.7-4.9

XP55P 1,000 1030

8.5 1.5 9.2 10.4-65.1 1.2-7.4

XP65P 300 1150

8.5 1.5 9.2 26.0-156.2 2.9-17.6