TLS Screwdriver Operating Instructions

Rev 3.3 (3/24/2017)

Corporate Headquarters: 1080 North 11th Street, San Jose, CA 95112 Phone: (408) 292-2214 Fax: (408) 292-2733

www.mountztorque.com

Calibrating Torque Screwdrivers

To calibrate torque screwdrivers either use a torque tester or torque sensor within the range of the torque screwdriver. For

torque screwdrivers calibrate torque in "Peak" mode with a torque tester or torque sensor. Make sure to apply the torque

slowly and smoothly.

1. Select a torque tester or torque sensor that covers the torque range of the screwdriver.

Connect screwdriver to the torque tester or torque sensor using the appropriate adapters as

needed.

2. Apply torque clockwise slowly until screwdriver 'slips' and note reading.

3. Adjust screwdriver to required torque setting as described below.

4. Test and repeat adjustment as necessary to obtain desired value.

5. Recalibrate torque screwdriver at prescribed intervals.

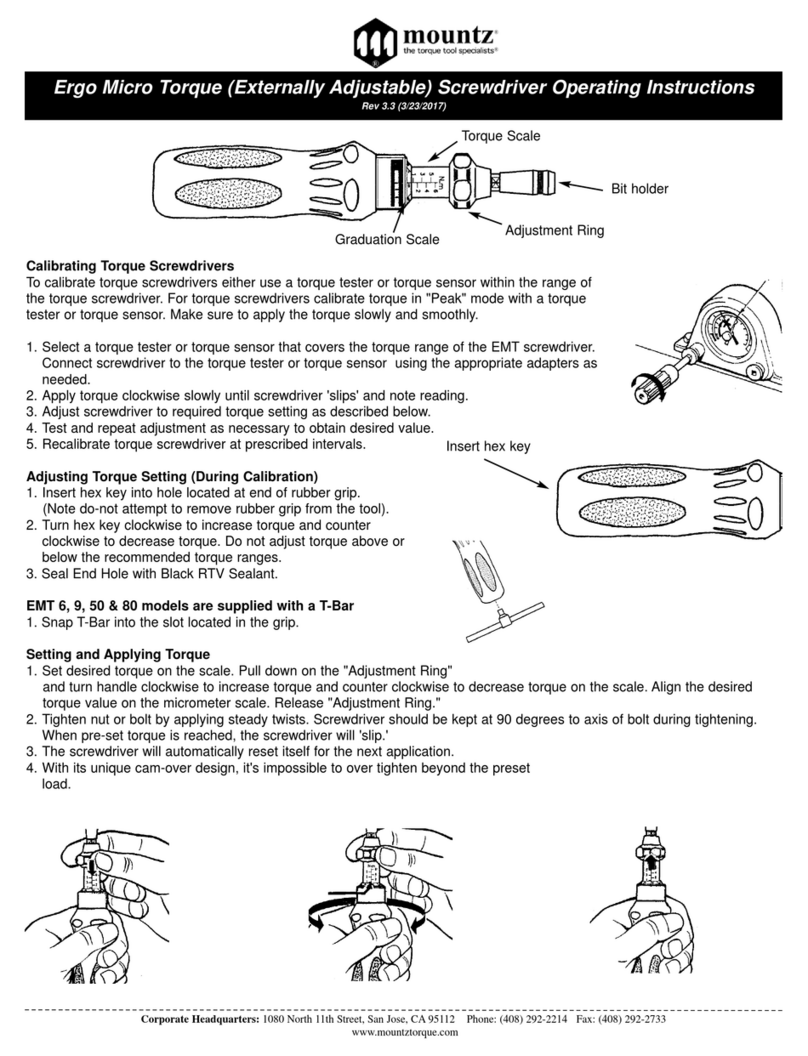

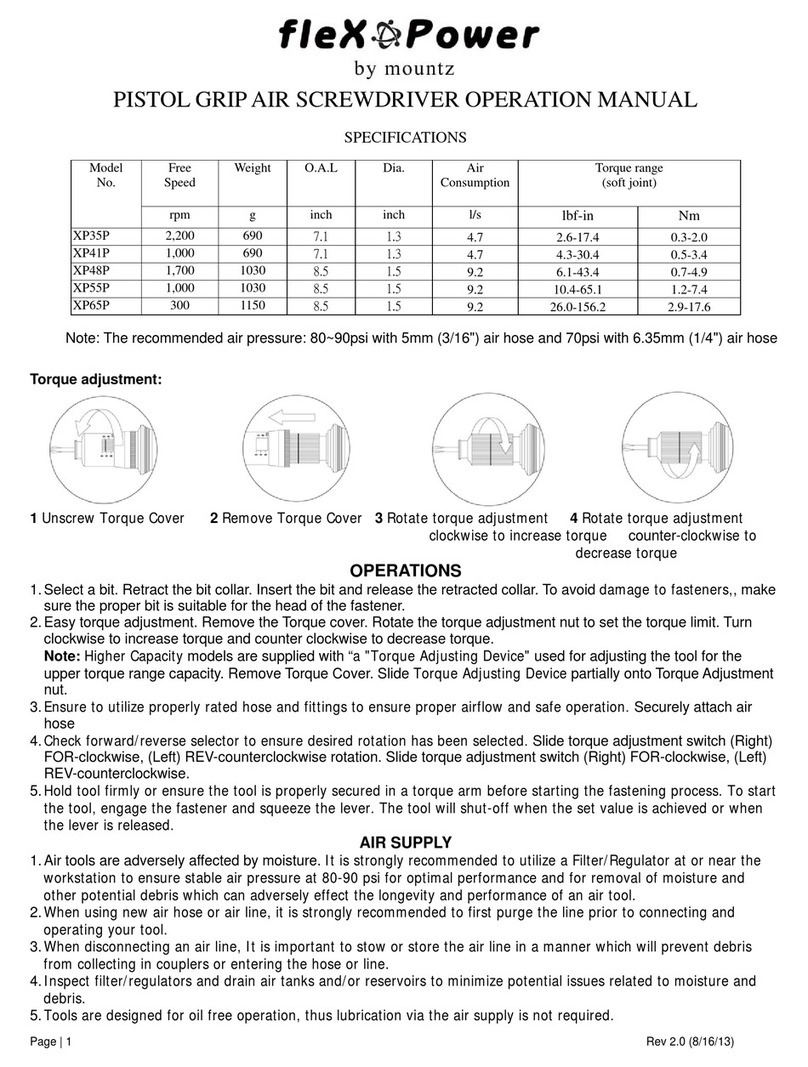

Adjusting Torque Setting for TLS Standard (TLS0406) and TLS1360 Models

1. Remove end cap from screwdriver anti-clockwise direction. Also remove the T-bar where fitted

(for TLS1360 models only)

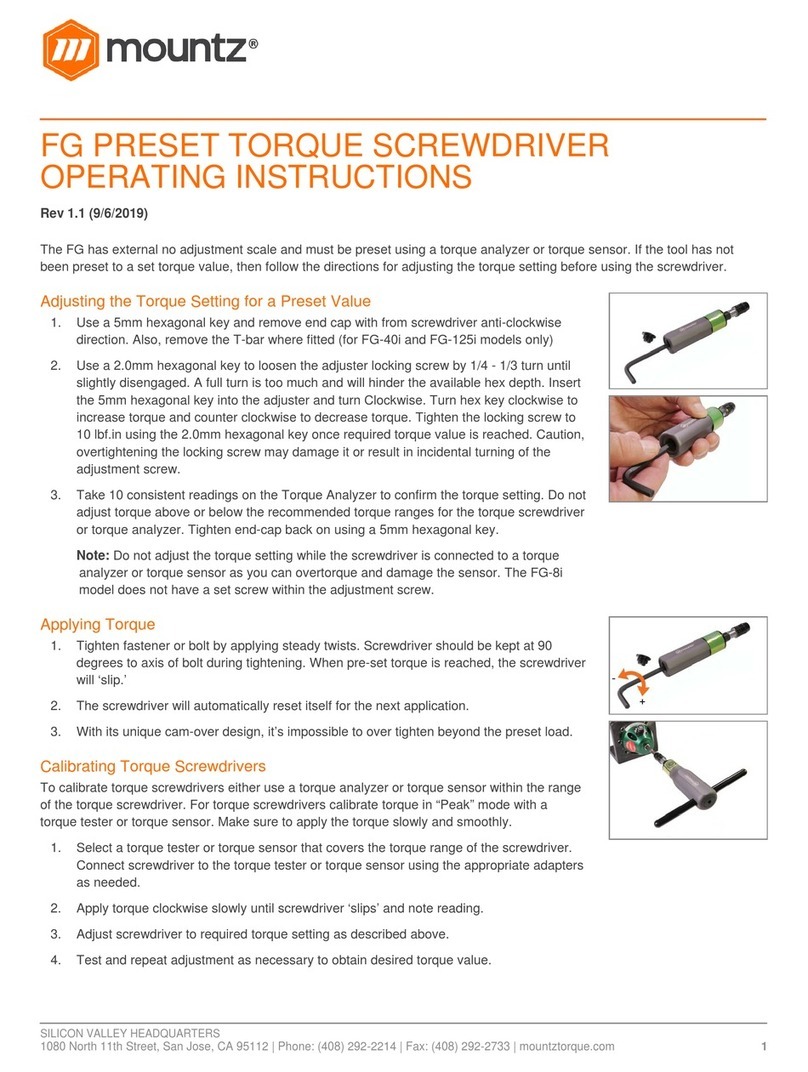

To Increase Torque Setting

1. Use a 2.0mm hexagon key to loosen the adjuster locking screw by ½ a turn. Insert the 3/16”

hexagon key into the adjuster and turn Clockwise. Tighten the locking screw to 1.5N.m Using

the 2.0mm hexagonal key once required torque value is reached.Turn hex key clockwise to

increase torque and counter clockwise to decrease torque.

To Decrease Torque Setting

1. Use a 2.0mm hexagon key to loosen the adjuster locking screw by ½ a turn. Insert the 3/16”

hexagon key into the adjuster and turn anti-clockwise below the required setting, then turn

clockwise to approach the new value. Tighten the locking screw to 1.5N.m using the 2.0mm

hexagonal key once required torque value is reached.

Note! Take 10 consistent readings on the Torque Analyzer to confirm the torque setting. Do

not adjust torque above or below the recommended torque ranges. Tighten end-cap back on.

The 2.0mm Hexagon key and adjuster locking screw are not required on the TLS 0022 and TLS Minor (TLS0135) models.

Adjusting Torque Setting for TLS 0022 and TLS Minor (TLS0135)

Models

1. Remove end cap from screwdriver anti-clockwise direction and insert

hex key.

2. Turn hex key clockwise to increase torque and counter

clockwise to decrease torque.

Note! Take 10 consistent readings on the Torque Analyzer to confirm

the torque setting. Do not adjust torque above or below the

recommended torque ranges. Tighten end-cap back on.

Applying Torque

1. Tighten nut or bolt by applying steady twists. Screwdriver should be kept at 90

degrees to axis of bolt during tightening. When pre-set torque is reached, the

screwdriver will ‘slip.’

2. The screwdriver will automatically reset itself for the next application.

3. With its unique cam-over design, it’s impossible to over tighten beyond the preset load.