SILICON VALLEY HEADQUARTERS

1080 North 11th Street, San Jose, CA 95112 | Phone: (408) 292-2214 | Fax: (408) 292-2733 | mountztorque.com

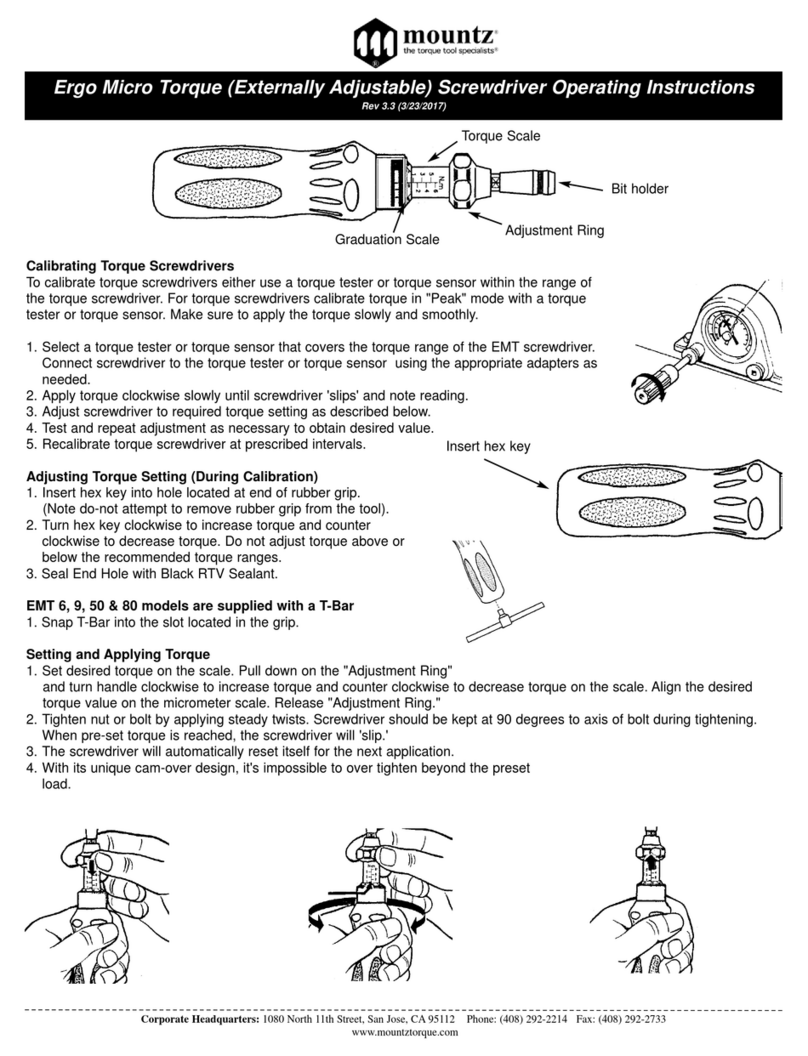

5. Recalibrate torque screwdriver at prescribed intervals.

Maintenance Schedule

Like an automobile, torque screwdrivers contain moving parts that require periodic servicing and lubrication.

Expected Tool Life

With normal use – 1,000,000 operations

Period Between Resetting of Torque

20,000 fastening operations. It is acknowledged that some tools may achieve 20,000 operations in a relatively short period of

time. Under these circumstances the user may decide, with the benefit of their experience, to increase the period between

calibration intervals.

Routine Maintenance

After 100,000 operations, strip, clean and re-grease the spring, bearings and internal components. Any worn components

should be replaced.

Note: Any tool that is dismantled during its life must be re-lubricated in accordance with the Mountz recommendations. Do not

clean tools by immersing them in solvent, as this will destroy the internal lubrication and cause failure of the tool.

Warranty

We’ve tested the FG preset torque screwdrivers over two million cycles in our controlled lab environment and we still can’t

break them!

It’s why we have an industry-leading warranty.

•Mountz FG tools are the only cam-over drivers on the market to offer a two-year unlimited warranty. If it breaks in any

way, we’ll fix it or replace it for free.

•Lifetime guarantee against manufacturing defects. We only make the highest quality products. This driver will not have a

defect, we stake our quality reputation on it.

•Warranty includes a free first calibration within the first year (if needed).

Testing and Servicing

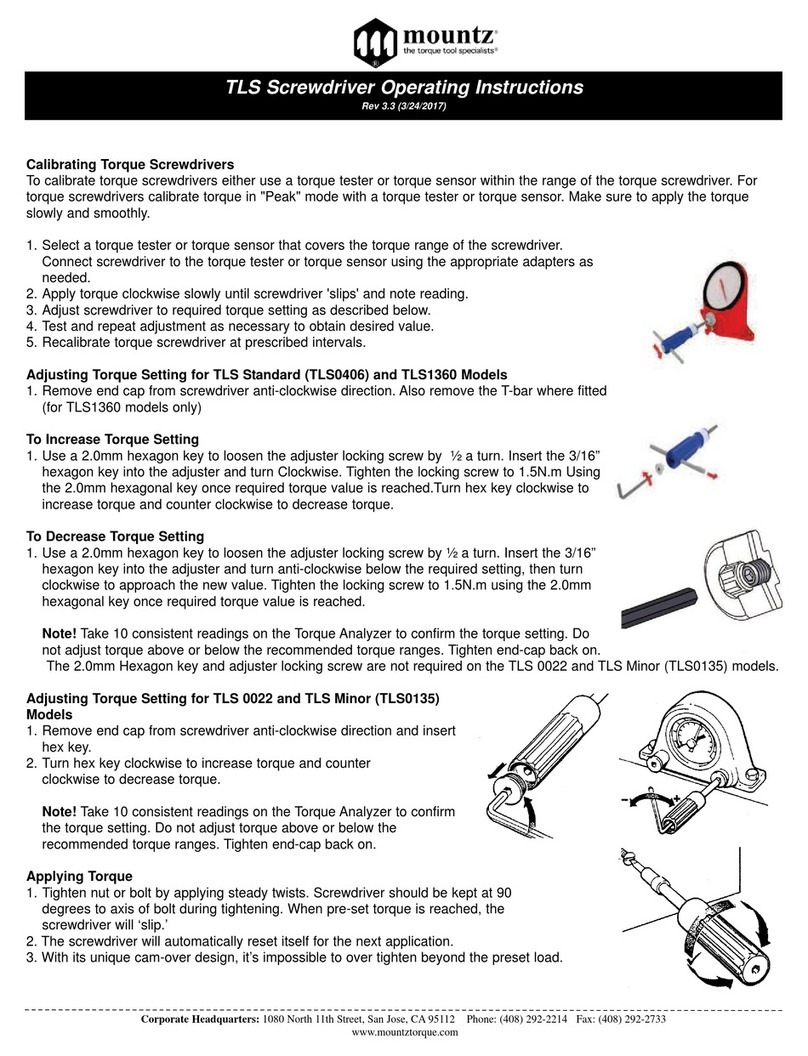

Torque tools go out of calibration with use. Calibrating a torque tool is a fine-tuning process of bringing the tool back within its

tolerance. Regular torque calibration of a hand screwdriver ensures accuracy, repeatable tool performance, and adherence to

international standards.

We recommend a general once a year calibration interval. However, it is the user’s organization that must determine suitable

intervals based upon equipment performance, application, degree of usage and management objectives.

Mountz Calibration and Repair Services

Mountz Inc. features an experienced calibration and repair staff. Our trained technicians

can calibrate and repair most any tool. Mountz provides rapid service with quality that you

can trust as we offer two state-of-the-art calibration lab and repair facilities that can

calibrate up to 20,000 lbf.ft.

About Mountz

Mountz, The Torque Tool Specialists®, has been a leader in the torque tool industry for

more than 50 years. Engineered in the Silicon Valley and serving the globe, Mountz

focuses on delivering high-quality torque products, services, and solutions to ensure

customers can always proceed with confidence. We are committed to forging a safer world

through precision and accuracy, and by innovating every day.

Mountz Service Locations

Eastern Service Center

19051 Underwood Rd.

Foley, AL 36535

Phone: (251) 943-4125

Fax: (251) 943-4979

Western Service Center

1080 N.11th Street

San Jose, CA 95112

Phone: (408) 292-2214

Fax: (408) 292-2733

www.mountztorque.com