VB-Series Operating Instructions

Rev 2.6 (5/28/13)

Corporate Headquarters: 1080 North 11th Street, San Jose, CA 95112 Phone: (408) 292-2214 Fax: (408) 292-2733

www.mountztorque.com

Operating the Tool

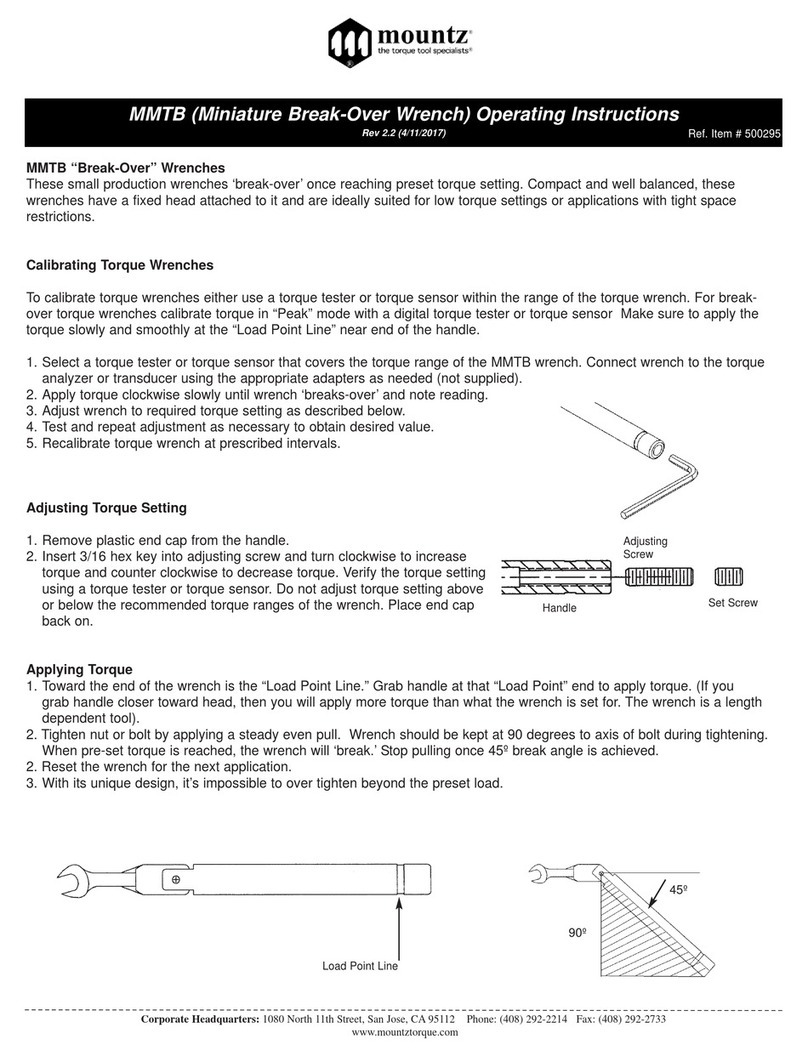

1. Select a bit. Retract the bit collar. Insert the bit and release the retracted

collar. To avoid damaging fasteners, make sure the proper bit is suitable for

the head of the fastener.

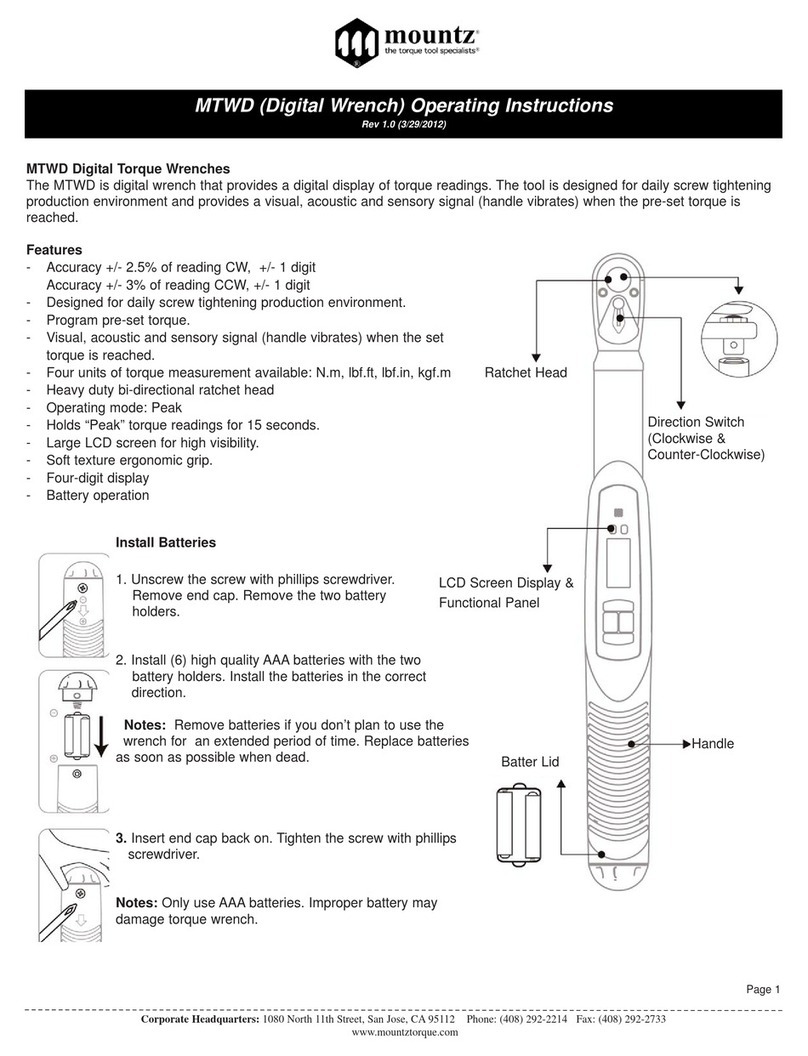

2. The torque limit is determined by the tension of the coil spring housed in

the torque adjustment nut. The tighter the coil spring is wound the higher

the torque limit is raised. See Torque Charts on page 2 to determine the

appropriate torque adjustment setting.

3. Rotate the torque adjustment nut to set the torque limit. Turn clockwise to

increase torque and counter clockwise to decrease torque. The scale

adjacent to the Torque Adjustment Nut is a reference guide. The torque

output from the driver can change depending on various fastening factors

like friction, type of joint, and the type material being used like a washer.

4. Make sure the FOR/STOP/REV switch is in the “Stop” position. Plug-in

power cord.

5. Turn driver on and check for proper rotation. FOR-clockwise,

REV-counterclockwise.

6. To apply torque, squeeze the lever (Push-to-Start models - place light

downward pressure on the nose of the driver). The driver will

automatically stop when the preset torque has been reached. Never

run the motor continuously for extended periods. Use tool intermittently:

(example 5 seconds on and 3.5 seconds off).

7. To remove the screw, turn the FOR/REV switch to REV.

CARE & Safety

1. The VB-Series screwdrivers are a precision torque control instrument and should be handled with care at all times.

2. Operate under safe conditions. Do not place in operation where such objects as hair, strings, clothing, etc. can become

tangled in the rotating bit.

4. Keep away from moisture. Never use in high humid, moist or damp environment.

5. Use the tool intermittently (example 5 seconds on & 3.5 seconds off).

6. Do not tighten more than 900 PCS of tapping screws during a period of 60 minutes.

7. When using the VB4504PS at high torque settings, please use a torque arm or Shock-Resistant stand with the tool. The

high impact on the operator’s hand may result in Carpal Tunnel Syndrome.

8. Never lubricate electrical parts.

9. Tool is not for tightening wood screws.

10. Use tool with proper voltage (120V).

11. While tools is in use, never change Forward and Reverse direction immediately.

12. Do not pull the cord as means to unplug the driver. Unplug driver using the plug-end.

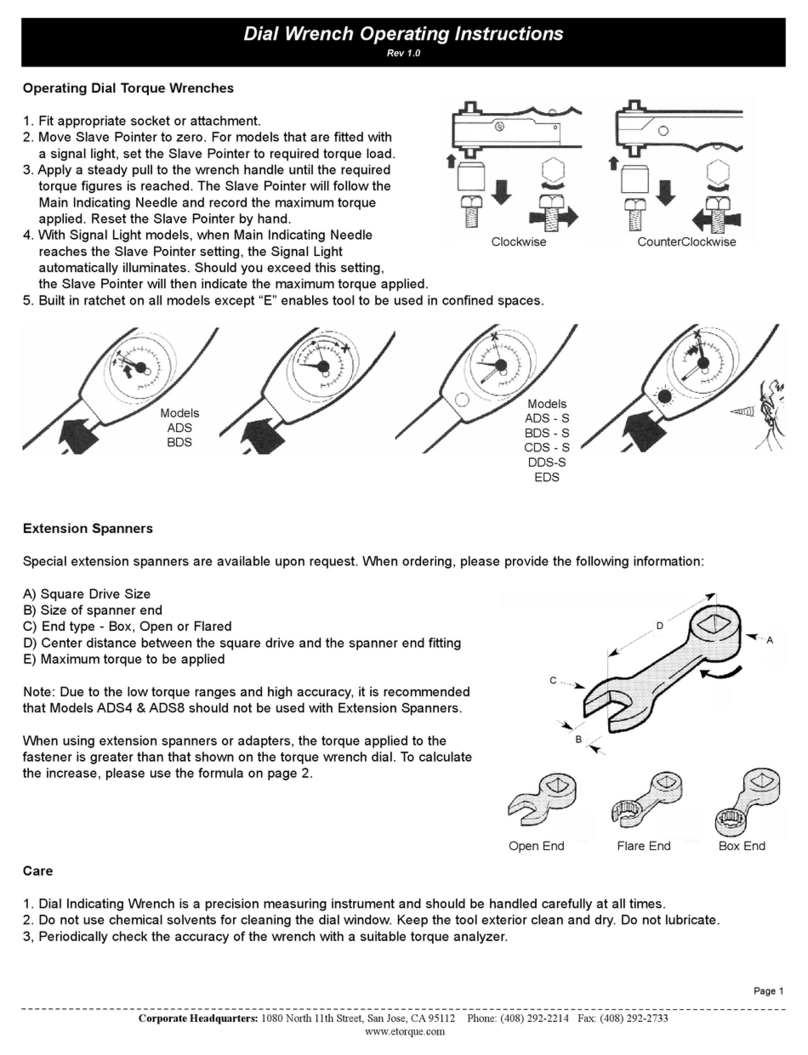

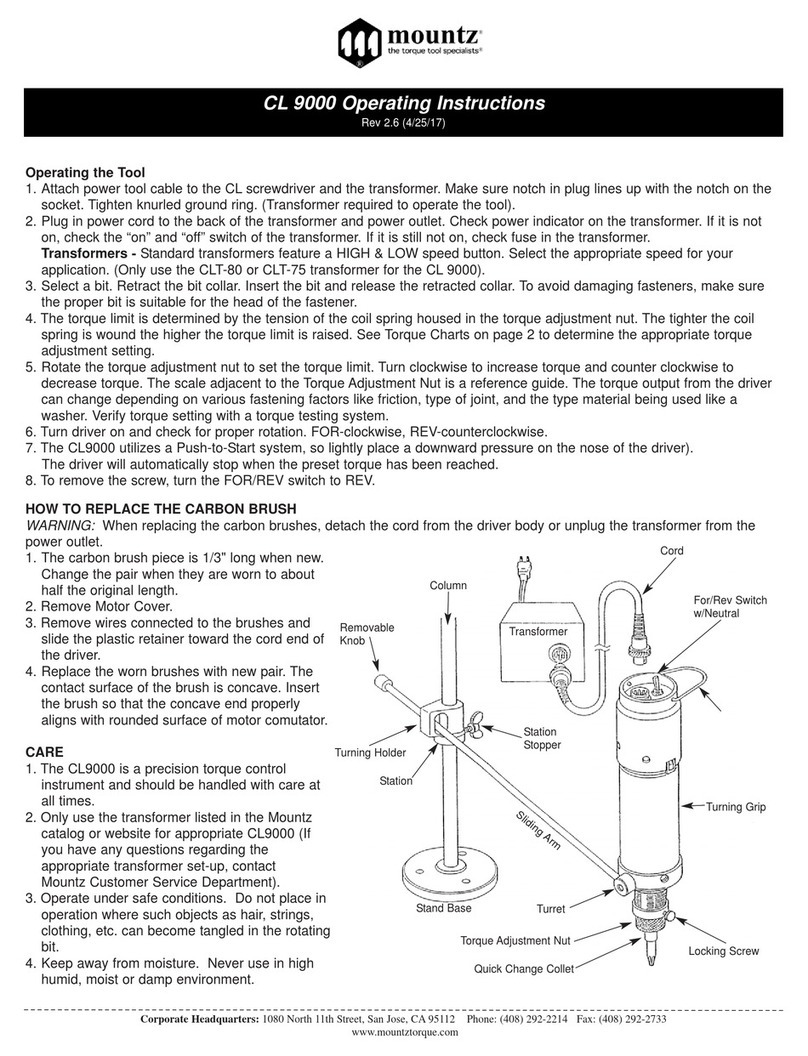

AC Plug

Cord

Hanger

For/Off/Rev

Switch

Lever

Torque

Adjusting Nut

Shaft Collar

Bit

Lever Model Push-to-Start Model

Scale

Cover