Greenlee / A Textron Company 94455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

CK06FT CrimpingTool

Maintenance

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection could

result in serious eye injury from

flying debris or hydraulic oil.

Skin injection hazard:

Do not use hands to check for oil

leaks. Oil under pressure easily

punctures skin. If injured, seek

medical attention immediately to

remove oil.

Failure to observe this warning could

result in serious injury, gangrene, or

death.

Do not use solvents or flammable

cleaners to clean the tool body.

Solvents could ignite, causing

serious injury or property damage.

Daily

Before use:

1. Inspect nibs for wear or damage such as cracks,

gouges, or chips.

2. Inspect the crimping tool for damage or leaks.

Return a damaged or leaking crimping tool to an

authorized Greenlee service center.

After use:

1. Use a damp cloth and mild detergent to clean the

housing. Allow the housing to dry.

2. Fully retract the ram. Place the crimping tool in the

carrying case and store in a cool, dry place.

Monthly

1. Thoroughly clean all surfaces.

2. Check the oil level.

3. Perform the “Periodic Pressure Relief Valve Check.”

Annually or After 10,000 Crimps

1. Replace the hydraulic oil.

2. Send the tool to an authorized Greenlee service

center for inspection.

Checking the Oil Level

1. Remove the two screws that retain the tank housing

cover. Remove the tank housing cover.

2. Point the crimping head downward and remove the

oil reservoir plug. Fill reservoir if necessary.

3. Replace the oil plug and tank housing cover.

Recommended Hydraulic Oils

AVIA®HVI 15

Shell Tellus T 15

Mobil®DTE 11M

NUTO®H 15

Periodic Pressure ReliefValve Check

Keep hands away from the crimping

tool head when crimping.

Failure to observe this warning can

result in severe injury or death.

Relief valve adjustments must be done by an

authorized service center.

Test the crimping tool periodically to ensure that the

pressure relief valve activates at the proper pressure.

Testing the Crimping Tool

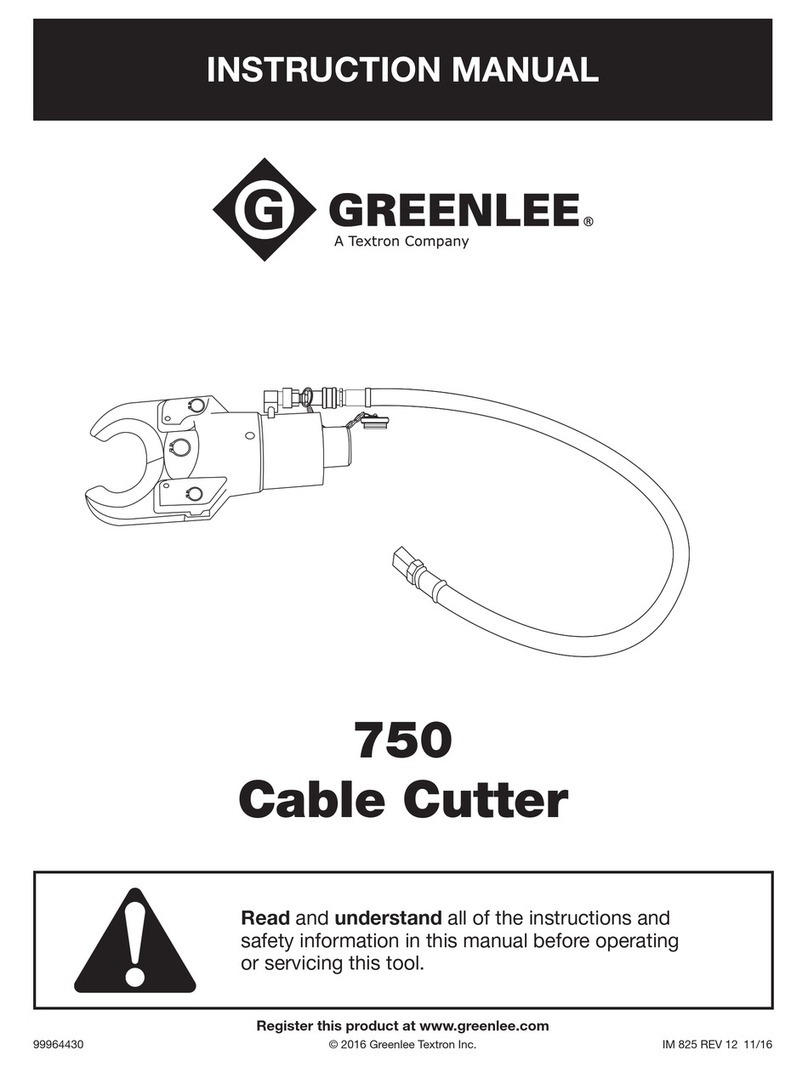

1. Center a test slug between the nibs.

2. Pull the trigger to advance the nibs. Hold the trigger

down until the pressure relief valve activates.

3. After achieving pressure relief, the ram automatically

returns to the start position and the nibs retract.

4. Evaluate the test slug as follows:

•If the test slug does not

fit into GO slot, the

pressure relief valve is

set too high. Send the

crimping tool to an

authorized Greenlee

service center.

•If the test slug fits into

the GO slot, the pres-

sure relief valve is set

correctly.

•If the test slug fits into the NO GO slot, the pres-

sure relief valve is set too low. Send the crimping

tool to an authorized Greenlee service center.

GO

NO GO